Flexible gravure ink formula design

The formula design principle of this type of ink is generally that the ink should have better fluidity and viscosity. Dry quickly and properly. Adhesion to substrates is better. In addition, the solvent in the ink cannot affect the printing plate and rubber roller. The ink must not have an odor after drying. Have good storage stability. If it is a pigment-based ink, after long-term storage and precipitation , it should be easy to redisperse after stirring, etc. Of course, the above-mentioned contents are mainly related to several aspects such as colored bodies (ray materials, dyes), binders (resins), solvents and kinetic agents, etc., and are now described as follows:

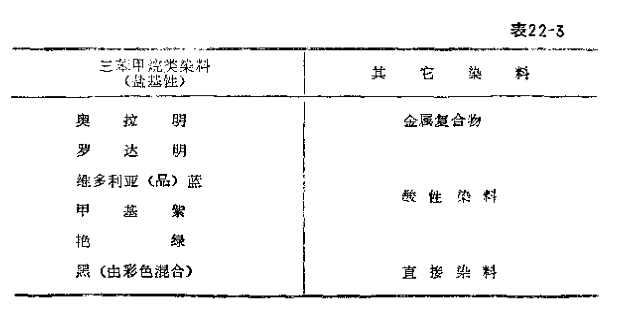

Because this type of ink is mainly used to print packaging materials, the requirements for color are relatively high. The requirements for forehead color mainly include two categories, one is bright colors , and the other is transparency. Bright colors are easy to understand, and only ink can see the items in the printed matter package, which can increase the look and feel of the package. - Generally speaking, most of the dyes are transparent colored bodies after dissolving. When they are printed on metallic glossy paper (such as aluminum clamps), they can show special glossy colors , thus greatly increasing the color of the printed matter. vividness. The names of dyes used in this type of ink are shown in Table 22-3.

The transparency of pigments varies greatly. Due to its strong hiding power is often used to print the background color (the first color) as a background foil. When printing on paper with strong absorbency, dyes and pigments are often mixed to prepare inks. Although such oils have better rheological properties, because the dyes have better solubility is relatively low, while the pigments have better rheological properties. Because it does not dissolve, it will increase the viscosity of the ink (the carbon black is relatively small in co-particles, so the prepared ink is often thixotropic). When mixing several pigments in solvent-based inks, pay special attention to color changes. For example, adding a small amount of red to yellow will cause the red to fade easily in the storage (even during processing). It may be due to the reaction between Yanke and the linking material . From an economic point of view, it is also desirable to use a part of the dye.

From the perspective of colored bodies, flexographic letterpress inks can be divided into three types: near-material type, dye plastic , and pigment and dye mixed type.

Considering that the ink may come into contact with food, the toxicological conditions of the colored body should be paid attention to (the dumping materials containing lead and cadmium are generally prohibited internationally). Generally speaking, pigments should be resistant to solvents used in inks and waxes (there are many packaging materials such as candy wrappers that need to be coated with a layer of wax). When it is used for printing thin and thin materials, attention should also be paid to the migration of colored bodies (most purple pigments have migration).

The selection of binder (resin) requires sufficient experience. With the difference of substrates, the resins used are also different. Therefore, the range of resins is quite wide.

Polyamine resin has good adhesion to various substances (especially suitable for printing polyolefin films), plus good dispersion, high gloss, fast solvent release , and good printing performance (Shan ink It is easier to understand), prints are clear, etc., so it is a relatively common resin in flexographic letterpress inks. However, due to its poor heat resistance, it cannot be used alone when it is used in composite packaging.

Alcohol-soluble polyamide resins can be filled with alcohols as solvents. In fact, co-solvents are generally used. Because the ink is easy to gel (freeze) when alcohol is used alone, it is beneficial to use some naphtha. For example, a pulp amide resin has a gel (freeze) point of 10C in monoethanol, and when 50% ethyl alcohol is used, When 50% petroleum solvent, its gel (freezing) point can drop to minus 10C. Also, co-solvents dry faster than single solvents. Nitrocellulose, cellulose distilled ester or ether can be used in most solvent-based flexographic letterpress inks. It has good heat resistance, scratch resistance, and deep-friction resistance . Used alone, it is often combined with other resins (such as polyamide etc.), and the blending property is relatively good.

Solvent-soluble acrylic resin has good adhesion to ethylene thin film , and has good heat resistance when used with nitrocellulose, and can be used in thermal compounding process (good to styrene and other vinyl substances) Adhesion). However, resins such as caps tend to be drawn and form a network, and the prints are not very clear in comparison. The acid groups on the carboxylated acrylic resin can be used in high-quality water-based inks that are resistant to friction and scratches after being neutralized with amines or other bases. Luxol resins can be used in high heat-resistant water-based inks. Rosin-modified malic acid resin can be used in some solvent-based inks, and has the characteristics of good gloss and excellent printing performance. This kind of resin with high acid value can also be used in water-based ink towels after being treated .

Shellac is an earlier resin used in flexible letterpress inks. Because of its good alcohol solubility and friction resistance, it is still used in some current water-based inks. Polyketone resins are mainly used in inks for composite packaging because of their better adhesion . Phenolic resins are mainly used in dye-based inks, which can react with dyes to increase light resistance and reduce oil bleeding. Polyurethane Inflammation Pro is currently mainly used as a binder, and may also be used in lithograph .

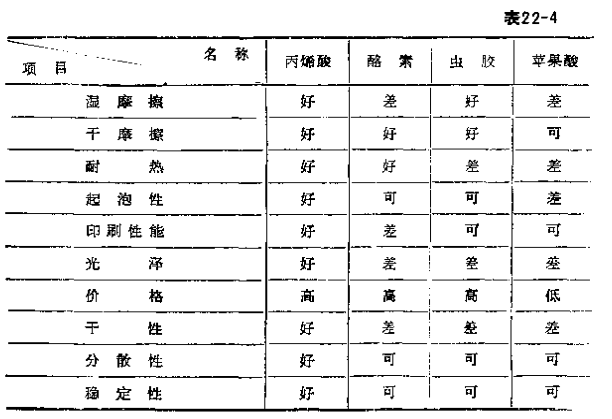

The characteristics and prices of several representative resins used in water-based inks are compared in Table 22-4.

Generally speaking, the binder in this type of ink should have a relatively high resin content at an appropriate printing viscosity , because not only the printed product has a high gloss, but also the printing performance is relatively good. The binder should also have color, low viscosity, and fast drying (the solvent is easy to "run away". The solvent release of the resin is very important, otherwise it will stick into blocks, residual odor, and bubbles will be generated during compounding. If there are too many plasticizers or the resin itself is relatively soft - when the softening point is low, the ink may still be sticky and stick to the disadvantages of sticking ), good dispersibility, and strong adhesion (adhesion) (the ink film Softness is also very important for flexible packaging printing), good printing performance (in solvent- based inks, printing performance almost mainly refers to the solubility and resolubility of the resin - that is, when the printing plate is pressed The oil on the plate can be redissolved , and the solvent release), can accommodate - quantitative plasticizer, heat resistance (heat sealing process), friction resistance and resistance to various Various application properties, such as alcohol resistance, freezing etc.

- 1Significance and method of INKS surface tension detection

- 2Testing and test methods for performance of different inks

- 3Determination of Wear Resistance of Ink Film by Abrasion Meter

- 4Thixotropy - the viscosity of inks and paints

- 5What are the subjects of ink testing for food, pharmaceutical and other packaging?

- 6ASTM Ink Tape Testing

- 7What is the cheese and oil resistance of ink?

- 8How to test the heat resistance of ink?

- 9Test method for wax resistance of ink