Type of ink scraper

The scraper is composed of two parts, a rubber strip and a jig, and can be divided into two types of scrapers for manual printing and mechanical printing according to the way of use. Fixtures are usually made of wood and aluminum metal materials. The connection between the rubber strip and the clamp is mainly fixed by screws.

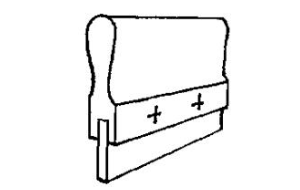

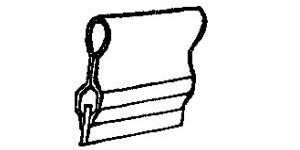

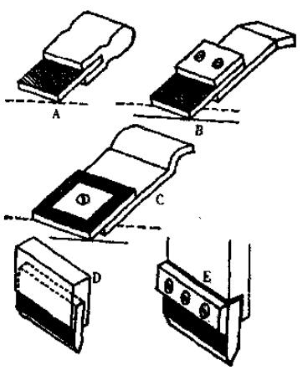

The scraper used for manual printing, as shown in Figure 7-23 and Figure 7-24 , requires that the handle part should be easy to hold and easy to use. Scrapers and fixtures for screen printing machines require high processing precision and are easy to install and use.

Figure 7- 23 Squeegee for wooden hand-printing

Figure 7-24 Squeegee for aluminum hand printing

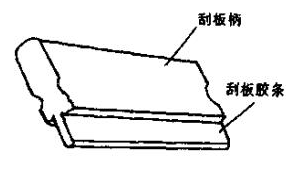

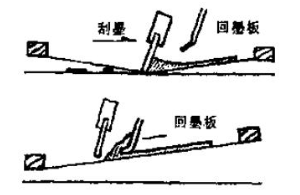

The so-called screen printing squeegee usually refers to the ink squeegee. In automatic screen printing, two scrapers, the ink scraper and the ink return board, are often used to alternately move back and forth during printing. According to different purposes, screen printing scrapers can be divided into hand-used scrapers (as shown in Figure 7-25 and Figure 7-26 ) and machine-used scrapers (as shown in Figure 7-27)

In manual screen printing, both printing and ink return strokes are completed by a squeegee. During machine printing, printing and ink return are completed with two kinds of ink plates respectively. Among them, the ink return plate is a metal plate with a thickness of about 2mm, and the blade is rounded. During the printing process, the two ink plates rise and fall alternately.

Figure 7-25 Hand squeegee

Figure 7-26 Two types of scrapers for machine printing

Figure 7-27 Squeegee of flat printing machine and curved surface printing machine

- 1Ink Rub Resistance Tester: Core Equipment and Application Analysis of Wear Resistance Testing for Printing Products

- 2Application of Manual Ink Proofer

- 3Ink decolorization testing machine tests ink friction resistance

- 4GB/T36650 Optical Fiber Coloring Ink Performance Testing Scheme [With Instrument Parameters]

- 5How to calculate flexo ink consumption?

- 6Keep your screen printing customers happy with accurate printing colors

- 7Maintain your screen printing quality with proper screen tension

- 8Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 9Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

向华,龚逸仙,李军,林木雄,欧建志 - 《《用于塑料薄膜的荧光凹印油墨的制备与性能研究》》