Friction resistance of screen printing ink film

The ink film is printed on the soft polyethylene film and should be able to bend with the material. If the adhesion is good but cannot bend as well as the film, the ink film will crack. Advertising posters are generally used in matte inks for paper printing such as posters. Commodity advertisements and packaging paper printed with this ink often crack when they are folded and stacked after printing. The poor flexibility of the ink film is due to the fact that more pigments and fillers are added in the ratio and less linking material. Therefore, the resistance of the film to withstand bending can be improved by increasing the linking material. In order to enhance the coloring power and hiding power of yellow and white inks, the proportion of pigments is generally relatively large, so this problem is also more obvious.

If there are many pigments and fillers in the mixing ratio of the ink, although the dullness will be increased, the formed film will also become brittle, just like the chalk used for writing blackboards, it is easy to peel off in powder form. This peeling phenomenon is called "powdering." When the printed matter is stacked, the ink film that is easy to be powdered will cause the back of the printed matter to contaminate each other due to mutual friction. In addition, even if a printed matter with a firm film has been formed, if it is posted outdoors, it will be exposed to wind, rain, and sunlight for a long time, which will cause the aging of the linking material due to the change of surface over time, resulting in chalking. Therefore, the most suitable ink should be selected according to the resistance requirements of the printing ink film.

The component that affects the physical strength of the ink film is mainly the ink binder, and the color fastness is the pigment. If you can mix the two well, it will be the most satisfactory oil V that is easy to print. To check the ink film layer on the metal, bend the metal plate coated with the ink layer to 99°, observe the change of the ink film layer in the bent part, repeat how many tests in this way, and check the strength of the ink film layer. For this degree of tolerance against bending; call it flexibility. Screen printing also requires that the oil-cutter film has similar flexibility. That is to say, for soft printing surfaces such as films, textiles, and papers, it is required that even if the oily film is rubbed vigorously, it cannot be pulverized and peeled off. For friction resistance, it is not only necessary to test in the air, but also to immerse the printed matter in water and other solvents. Sometimes several methods are used to test it. In short, it should be tested according to the requirements of the printed matter.

- 1Ink Rub Resistance Tester: Core Equipment and Application Analysis of Wear Resistance Testing for Printing Products

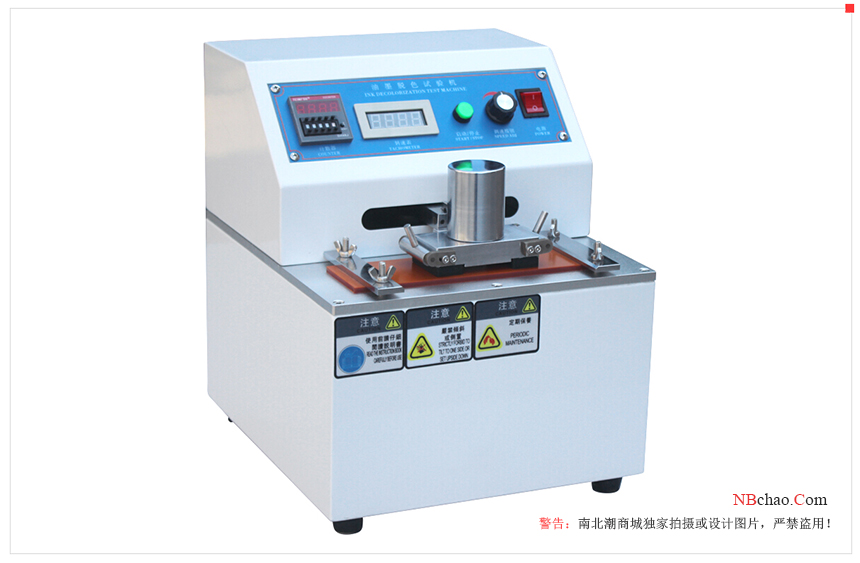

- 2Ink decolorization testing machine tests ink friction resistance

- 3GB/T36650 Optical Fiber Coloring Ink Performance Testing Scheme [With Instrument Parameters]

- 4Transfer phase of ink transport on the printing press

- 5What are the functions and benefits of ink friction testing?

- 6TAPPI T 830-2018: Ink Friction Test of Container Plates

- 7Specific steps for ink adhesion selection

- 8What is the light resistance and chemical resistance of screen printing inks?

- 9Stickiness of screen printing ink