Analysis of common performance definitions for paper inspection

Bend Test/Bend Resistance

This test gives a measure of the "stiffness" of the paper, which is a measure of the force required to bend the sample at a specified angle. Stiffness is important for cardboard, boxboard, corrugated and printing paper. This property is measured by the resistance of rectangular samples to bending forces. Usually expressed in millinewtons (mN)

brightness

Brightness is an optical property of paper that measures the reflectance/reflectance of blue light at a dominant wavelength of 457 nm. Obtaining a brightness value at this wavelength indicates the quality of bleaching in the pulp. Pulp bleaching is done to remove residual "lignin" (the glue that holds the cellulose fibers together) which, if present, gives the paper a creamy/yellowish appearance. Since lignin absorbs strongly at 457 nm, brightness is measured at this wavelength. Commonly followed testing standards are TAPPI T452, ISO (2469 and 2470) and ASTM methods. This property is an important seller of paper, as lighter papers are more attractive than less bright papers.

Opacity

"Opacity" is a fundamental optical property of paper, which is a measure of the amount of light that can be transmitted or absorbed. The greater the opacity value of the paper, the less light it will transmit or allow to pass, and vice versa. Opacity is a very important property to consider when printing on many types of paper such as duplex, fixed, tracer, etc. The opacity of paper is affected by many factors and factors, such as the thickness/grammage of the paper, the amount and quantity of mass fillers, the degree of bleaching of the fibers, the papermaking process of coating, beating, pressing, calendering, super calendering, etc. It is a sheet of paper measured by the ratio of the percentage of light that is absorbed or reflected (diffuse reflectance), and is measured using an "opacity meter". There are two measurement methods, one is the "contrast ratio method" and the other is the "diffuse opacity method". The standard test methods followed are TAPPI T425 and ISO 2471.

Contrast method for turbidity measurement

This measure of "paper opacity" calculates opacity as the ratio of the reflectance (diffuse reflectance) of a paper sample with a black body or paper backing to the reflectance (diffuse reflectance) of the paper with a white backing. A subject whose reflectivity is known.

Diffusion Opacity Method to Measure Opacity

In the Diffuse Opacity Method, opacity is measured by taking the reflectance of a paper sample with a black body backing (diffuse reflectance) compared to the reflectance of a paper backed by multiple sheets or stacks of heavy paper (diffuse reflectance). reflection) ratio. the same test paper. Many believe that this method provides a better estimate of the opacity of the paper pattern than the "contrast ratio method".

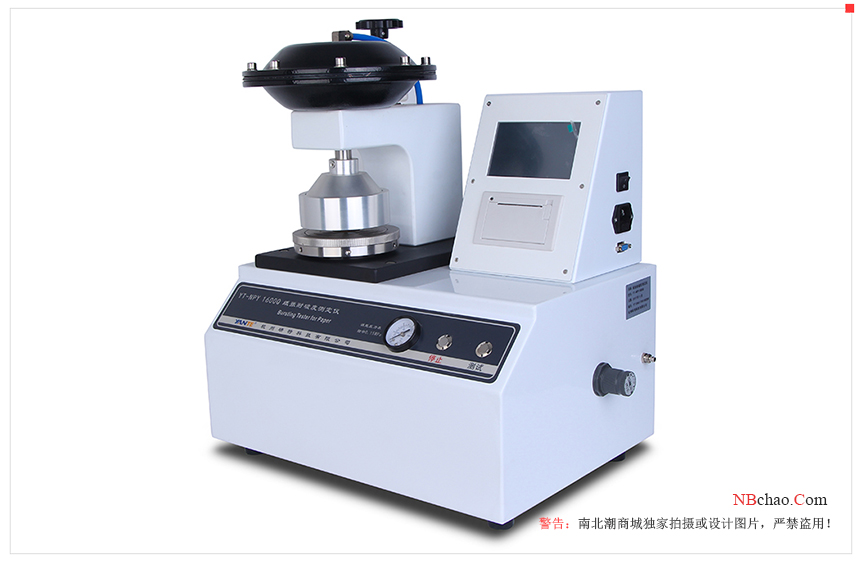

bursting strength of paper

Bursting strength indicates how much pressure a paper can withstand before it ruptures. This is one of the oldest tests done on paper to test its strength or resistance to breaking. This property is important for paper or paperboard intended for packaging purposes such as paper bags, corrugated boxes, etc. Bursting strength is measured by the maximum hydrostatic pressure required to rupture/rupture a paper sample by increasing the uniformly applied pressure through a rubber membrane of specified size across its sides. This property depends on many factors such as fiber quality in terms of type, ratio/amount, method of its preparation, degree of beating and refining and use of additives and fillers. This test is usually performed using a "Mullen Tester".

outbreak index

The purpose of determining the burst index is to facilitate the comparison of the burst strength of papers with different grammages (g/m2), or to standardize the burst strength of various papers. It is obtained or calculated by dividing the burst strength (unit: kPa) of the paper sample by the paper grammage (unit: g/m2).

compressibility

The compressibility of a paper sample is the reduction in thickness upon application of compressive force/pressure. In practice, it is calculated as the reduction in surface roughness when two consecutive roughness measurements are made without moving the test piece at the two standard contact pressures specified in the standard method. In simple terms, it refers to the paper's ability to be squeezed (on a flat surface) and then return to its original state. This property is an important indicator of paper printability. The high compressibility of paper can be used to produce good printed images. The compressibility of paper is a function of its apparent density, degree of fiber refinement, and degree of calendering and overcalendering. The extent of this parameter, as well as other indicators such as elasticity,

smash value

This test is a measure of the strength of aggregates and is commonly used to make concrete. It involves a standard compression of 400kN in a die of a known mass of individual particle size aggregates and then measuring the percentage of crushed particles.

elasticity

This property of the paper determines how much or to what extent its original dimensions and surface contours are restored after the compressive force is removed, as in printing. The resilience of paper depends on many factors, especially those related to the papermaking process, such as qualities such as fiber refining, calendering, supercalendering, and other parameters such as density, humidity, etc. Controls or defines the "print pad" of the paper in combination with its resilience, compressibility and stiffness/softness. Elasticity is a key point considered in "letterpress" and "gravure printing".

density

The density or specific gravity of a paper is its weight per unit volume, which is obtained by dividing the basis weight by the caliper. Paper density is usually expressed in g/cm3 or kg/m3, which indicates the compactness of paper. Typically, paper densities range from 0.5 to 0.8 g/cm3 or 500 to 800 kg/m3.

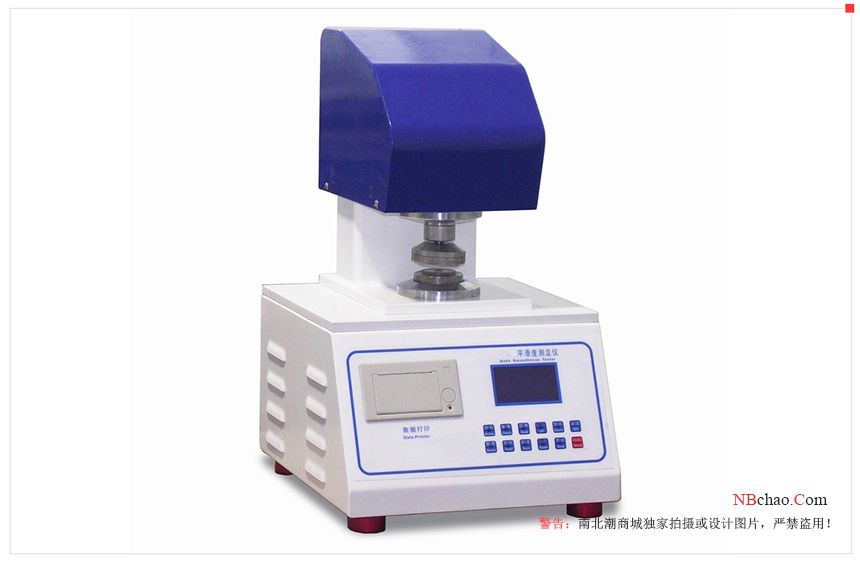

thickness or thickness

The caliper or caliper of paper, cardboard and tissue paper is its thickness, measured after applying a static load for a specified time. The importance of this measurement in assessing the uniformity of the paper across its length and width cannot be overemphasized. This property can affect some basic properties of the paper, such as strength, optical properties, roll quality, etc., and can also affect aspects of printability and runnability when printing. Thickness is controlled by many factors such as grammage, fineness of pulp and degree of wet pressing, calendering and overcalendering. This property is very important for filling cardstock, printer paper, saturated paper, etc. Using a micrometer for measurement, you can measure two shapes that are circular, flat, or parallel under a pressure of 1 kg/cm2. Test results are reported in μm. The standard testing protocol followed is TAPPI T411. Swell thickness is the thickness of a sheet of paper calculated from the thickness of several sheets.

Short Span Compression Test

The "Short Span Compression" test measures the compressive strength of paper and especially corrugated cardboard materials under very short compression spans. Grips are generally designed to prevent "buckling" of the test piece during testing. The standard test methods generally followed are TAPPI T826 and ISO 9895.

ring pressure test

The "Ring Crush" test measures the resistance of paper or corrugated board formed into a cylinder to compressive forces at the edges. This test helps evaluate the performance characteristics of a paper or corrugated box component so that it can withstand damage during shipping or stacking. The test results are expressed in kN/m, and the standard test methods adopted are TAPPI T818 and TAPPI T822.

Paper weight

The grammage or "basic weight" of paper, cardboard or tissue is defined as the weight per unit area of the test sample which has been conditioned under the following conditions: temperature (0°C) 23 ± 1 and relative humidity (%RH) 50 ±2. Gram weight is usually expressed as g/m2. From a business point of view, it is an important attribute as it determines the buying criteria for a particular paper product.

Folding resistance (double fold)

The "Fold Endurance" of a paper tape is a measure of the tape's resistance to external pressure in the form of multiple folds before breaking. This test determines the suitability of a paper type for use under repeated folding, bending and crumpling. Therefore, this test is suitable for papers that are subjected to such forces or are handled very frequently, such as currency paper, wrapping paper, maps, brochures, cartons, cover paper, bond paper, ledgers, etc. Currency paper has a high folding resistance. Factors affecting this property of paper include fiber length, fiber strength, moisture content, use of fillers, etc. To study the aging properties of paper, the folding endurance values before and after accelerated environmental aging were utilized. Quantitatively, it refers to the number of double folds associated with a specified load, the number of times a paper strip of a particular size can withstand before breaking. There are four different instrument types or designs that can be used to perform this test, and they will produce different test results due to variations in applied strip load, strip folding angle, and folding speed. Tests using different instruments are carried out according to separate standards, for example, according to TAPPI T423 for a Schopper type Tester and according to TAPPI T511 for an MIT type Tester. Paper associated with a specific load, of specific dimensions, can withstand it before breaking.

rigidity

Paper stiffness refers to the ability of a test sample to withstand bending forces. Determines the force required to bend a pattern to a specified angle. Stiffness is usually expressed in two forms: (1) Bending stiffness: refers to the resistance of paper to externally applied bending forces. This is also called "stiffness". (2) Handling stiffness: Refers to the ability of paper to support its own weight. Factors that affect paper stiffness include the type of fibers used, the degree of refinement of the fibers, the grammage, thickness and bulk of the paper. Stiffness is an important consideration for some papers such as containerboard, corrugated box, bond and printer paper. Measurements can be made using different types of instruments using different conditions. For example, Clarke stiffness measures stiffness in terms of the free length (in centimeters) of a paper strip bent under its own weight. According to TAPPI T451. Take measurements.

smoothness/roughness

This property of paper is a measure of the flatness or profile of the paper's surface. The profile or appearance of a paper surface can be described in terms like 'finish' and 'pattern'. Smoothness and roughness are inversely proportional and depend on many factors involved in the paper manufacturing process, such as the degree of refining of the fibers, degree of wet pressing, degree of calendering, degree of supercalendering, use of coatings, and the desired paper finish. Smoothness is an important parameter for writing, printing properties of paper, aesthetic value and is also important for paper bags. Paper smoothness is usually measured using an "air flow meter". These instruments make measurements based on the principle that the volume of the void between a paper and a flat surface such as glass is proportional to the smoothness or roughness of the paper, and the rate of airflow between these surfaces is proportional to the volume of the void present on the paper. Some instrument types are Bekk, Bendtsen, Sheffield and Print-surf smoothness Testers. Depending on the instrument used for testing, standard testing protocols vary.

Tear Strength/Strength

This property provides a measure of the paper's resistance to the tearing forces it is subjected to. It is measured in the longitudinal and transverse directions and is expressed in mN. Two types of instruments are used, Elmendorf and Trouser tearing instruments. Tear resistance depends on the degree of refinement of the fibers and the quality and amount of fillers used. The importance of this attribute cannot be overemphasized in the many applications involving cover stock, wrapping stock, bond stock and envelope stock. The standard test methods followed are TAPPI T414, TAPPI T470 and ISO 1974.

tensile strength

It is the force required to create a break in a strip of cardboard and is measured in the machine and cross directions (ie parallel and opposite to the grain direction). It is expressed in kN/m and indicates the ability of the paper to withstand tensile forces. Therefore, this property is an important consideration where paper needs to be used under high stretch conditions. Tensile strength indicates fiber strength, fiber bonding and fiber length. The standard test method followed is TAPPI T494.

Water Absorption and Cobb Test

"Water Absorption" is a measure of the amount of water absorbed by the wet surface of paper samples and wood panel materials. Water absorption expressed in grams/square meter

Ash test

Ash testing of paper provides an estimate of the amount of inorganic fillers and coatings (such as calcium carbonate, clay, and titanium dioxide) used in the papermaking process. This parameter is determined by complete combustion of organic matter at a specified temperature and then calculated from the weight of an oven-dried sample. Although the importance of this property of paper is limited, it is important in the case of ashless filter paper from Whatman's point of view. Measurement standards are TAPPI T413 and ISO 1762.

pH value

pH is an estimate of the concentration of hydrogen ions, so it refers to whether the paper is acidic or basic. pH is equal to the negative logarithm of the hydrogen ion concentration. Paper with a pH of less than 7 is acidic. If the pH is greater than 7, it is alkaline; if the pH is greater than 7, it is neutral. This property is related to the "permanence" of the paper. The pH of paper can be determined in various ways, for example: (1) Determine the pH of paper extract obtained by decomposition in hot distilled water. (2) The pH of the paper extract obtained by disintegration in cold distilled water was measured. (3) Measure the pH by using a wet electrode directly on the surface of the test paper. These three modes give different test results on the same paper sample.

-

JINGWEN JW-102C2Z paper Burst Tester$ 1556.00

-

-

-

-

-

-

-

-

- 1Application of Paper Thickness Gauge in Paper and Cardboard Thickness Test

- 2Test method for bursting resistance of paper and paperboard

- 3Roughness/Smoothness Test Method for Paper and Board

- 4What are the factors that affect the printing performance of paper

- 5How to calculate the rupture coefficient of paper and corrugated board?

- 6Why is the blasting factor important in the packaging industry?

- 7How does the rupture strength Tester check the quality of paper?

- 89 Corrugated Box Test Methods to Ensure Packaging Quality

- 9Method for determination of bursting resistance and folding resistance of paper

-

CHINA BLD-01C paper Thickness Gauge$ 425.00

-

-

-

-

-