What are the standard test methods for hard packaging?

包装设计和开发的完成似乎是重要任务的结束。但是工作真的完成了吗?不,不是。接下来是测试。

测试是整个包装周期中重要性无庸赘述的一部分,适当的程序实施对于确保开发的包装能够满足所有要求重要性无庸赘述。它给出了包装在运输过程中以及在装配线中的包装过程中将承受什么样的压力的想法。

现在,当我们谈到测试时,刚性包装是需要格外小心的事情。刚性包装主要包括硬质塑料瓶和塑料瓶,气雾剂瓶,铝瓶,玻璃瓶等。即使在其中,硬质塑料在包装和容器中也占很大的份额。它们用于食品工业,制药以及其他广泛产品中,例如化妆品或文具。刚性包装通常分为多个部分–瓶盖和容器分别制造。因此,刚性包装的测试可以分为两个部分:单个组件的测试和单个包装的测试。

以下是According to测试方法分类的一些刚性包装方法测试。

硬包装的完整测试

本节介绍应用于整个包装的包装测试方法。这些包括尺寸测试,抗裂测试,跌落测试 etc.。

外型尺寸

需要进行尺寸测试的原因是需要正确捆扎以及使用自动装配线进行填充和标记的能力。测试产品的高度,宽度,长度或直径。重量也经常测试。但是,装配线具有非常准确的机械,如果瓶子或罐子的尺寸不同,则可能无法正常工作。此外,在贴标签或密封时,正确的尺寸可确保自动化过程可以进行而不会出现任何错误。

溢出量

与尺寸密切相关的是填充能力。溢出容量是指瓶子或广口瓶充满边缘时的容量。这使制造商可以确定某些类型的产品是否将填充某些类型的瓶子。

抗环境应力开裂试验(ESCR)

抗环境应力龟裂性或ESCR测试是塑料瓶非常普遍的测试。硬质热塑性塑料瓶经常成为环境应力裂缝的受害者。随着时间的流逝,宠物瓶在暴露于天气时会变脆。塑料会随着时间的推移经历聚合物降解。这破坏了聚合物分子中的二级键。经过这种降解的塑料容器在暴露于任何形式的外部机械力时通常会破裂。硬包装的ESCR测试使制造商可以观察到聚合物降解对容器的影响,以及在长期保存后容器可以承受的压力。

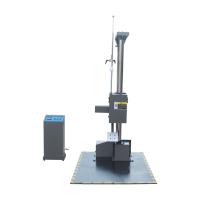

跌落测试

检查装满产品后容器是否能承受跌落。跌落测试具有某些标准,其中将装有产品的包装从一定高度掉落到坚硬的表面上。

泄漏测试

Leak testing allows manufacturers to see if a container can hold a product under different pressures or in different orientations. This is one of the important considerations in testing methods for packaging materials. Leak testing is usually broken down into two parts - vacuum leaks and inclined leaks.

In the case of testing for vacuum leaks, the container containing the product is placed in a vacuum-sealed chamber and the pressure in the chamber is reduced. If not manufactured properly, the walls or seal area of the package will start to leak.

The tilt leak test checks for different orientations of the bag for leaks.

transport test

Shipping testing checks how much pressure the package can withstand when shipped in bundles. When a package is transported from point A to point B, it is subjected to different types of stress as it travels on the road. These pressures are very different from those faced by retail stores or end users. Shipping tests check how much drops, tilts or vibrations the package can withstand.

individual component testing

Packaging testing standards appreciate the testing of individual components of packaging. Individual component testing will examine caps and closures. These include hinges, locking mechanisms, and the materials they are made of. Here are some tests performed on bottle caps and caps.

Bottle cap accessories

This test ensures that the lid fits properly on top of the container and does not cause any leaks.

Maximum Load Test/Compression Test

A top load test or compression test for rigid packaging checks how much load the closure can withstand before it ruptures. Rigid packaging testing is important because jars are stacked on top of each other when shipping jars. A peak load test or compression test gives an idea of how many bales can be stacked.

Hinge performance test

For closures with a hinge mechanism, the hinge performance test checks how much force the hinge can withstand and how durable it is, ie how many times the hinge can be opened or closed before it fails.

Flip opening force

On the flip tops that are common on ketchup bottles, the flip opening force determines how much force is required to open the lid. Opening the top cover can also break the hinge if the flap is opened with too much force.

Top cover removal force

The removal force of the cover should be greater than the opening force of the flip cover. This ensures that the lid fits snugly on top of the container.

Torque test

This test checks whether the lid can withstand the shear forces required to open or close the lid. This was primarily tested against bottle caps that open and close using a screw mechanism.

In addition to hard packaging, here you can also read about other materials available in the market.

Beyond that, there are a host of other standard testing strategies for specific rigid containers. Manufacturers use these tests to determine the durability and longevity of packaging. Rigid containers not only help manufacturers deliver products to consumers, but also keep them with consumers for a significant amount of time. Therefore, it is very important to perform quality control testing on plastic containers.

Still confused which is better for your business, rigid or flexible packaging? Read on for answers.

-

CHINA BLD-613D Single Wing Drop Machine$ 1830.00

-

-

-

-

-

-

-

-

- 1A complete guide to Dropping Tester types, applications and selection

- 2Application of Sealing Tester in chemical industry

- 3Application scheme of Sealing Tester in pharmaceutical industry

- 4Application of Sealing Tester in food industry

- 5Low/high Temperature Test Chamber for high-low temperature resistance test of rubber pads

- 6Low/high Temperature Test Chamber application test sealing strip temperature resistance

- 7Vertical impact drop test for transport packages

- 8Sealing performance test of soft packaging bags

- 9Sealing performance test of plastic packaging containers

-

-

-

CHINA NBC-1050B Double drum Drop Tester$ 1139.00

-

-

-