How does it work to calculate the coefficient of friction of plastic packaging films?

Plastic packaging is used in the market to package various products, be it heavy or light. In addition to that, heavy objects are not easy to break, but can be easily damaged. From this information, we can assume that almost every packaged item is susceptible to a certain degree of damage if it slips. Slippage is common with products wrapped in plastic. This is because plastic materials have less friction than paper or fiberboard materials. Its rough, structured surface provides greater friction than any plastic material. To fix the friction of the plastic film, it needs to be measured with a friction coefficient Tester first, and then the necessary changes can be made as needed to make it meet the requirements.

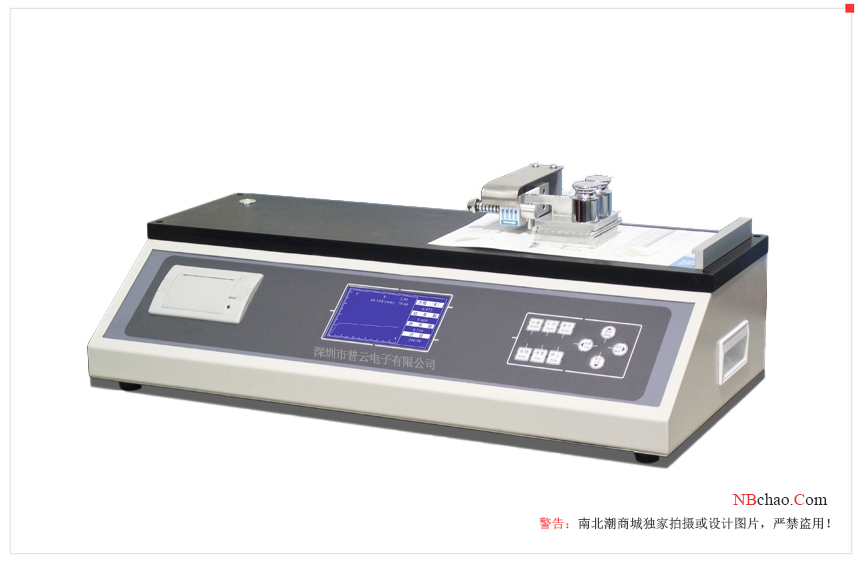

The device will help measure static and kinetic friction of plastic packaging films. Friction can be measured sample-to-sample or sample-to-glass and metal. The equipment is designed following international testing standards such as ASTM D618, ASTM D 883, BS 2782 and ASTM D1894. Among these standards, ASTM D 1894 defines a test method that can calculate the static and dynamic friction of plastic films and plastic films. sheet. The unit is constructed of mild steel material with a powder coat finish and bright chrome/zinc plating applied to the exterior for corrosion resistance. This is very important for long-term performance of the instrument without having to worry about the instrument being serviced all the time.

The SS slide is installed in the machine and is used to drag the sample material over other materials. Sample films are sliced and draped over blocks to slide over glass, metal, or the sample sheet itself. Equipped with a load cell to evenly distribute the force applied during sliding. VERY REMEMBER: Sliding friction should be evenly distributed over the entire surface, while recording test results or uneven friction will not meet the requirements. Digital force values are recorded via the digital unit of the machine. The indicator system is based on a microprocessor program that accurately measures the amount of friction applied while sliding. Easy-to-clamp grips are used in the machine to provide a smooth testing experience.

- 1Difference between static friction coefficient and dynamic friction coefficient

- 2What is the coefficient of friction and how is it determined?

- 3Test method of dynamic friction coefficient and static friction coefficient

- 4Why is coefficient of friction testing important?

- 5What are the packaging quality test methods?