What is a paper and packaging test instrument? its corresponding standard

Paper packaging and shipping tests are designed to keep products safe at their destination. In fact, packaging, transportation, distribution and packaging processing are a huge and complex process, and the quantities are huge and different. Laboratory simulation testing will be a simple, fast, effective and low-cost method for evaluating the performance of packaging protection designs under actual use conditions. The tested paper packaging can thus ensure its stability, environmental protection and recycling meet the national indicators. So, what are our common paper and packaging material testing instruments?

Corrugated box crushing test machine GT-N09

The Crush Tester Machine has been carefully designed using modern mechanical design theories, ergonomic design standards and microprocessor programs.

Edge testing machine standard:

ISO 3035, ISO 3037, ISO 7263, TAPPI-T472, TAPPI 811, TAPPI T838, JIS-P8126, GB/T 2679.8, GB/T 6546, GB/T 6548, GB/T 2679.6

Four-post carton compression Tester (computer control) GT-N02D

Box compression Testers are used to determine the cargo capacity and stack height of cartons. Corrugated box testing equipment is suitable for compression and retention testing of various packages and cartons. Capacity: 0-10KN, 20KN, 30KN, 50KN. 70KN, 100KN (optional)

Automatic Bursting Strength Tester (High Pressure) GT-N29C

The Bursting Strength Tester is ideal for cartons, cardboard, corrugated cardboard, cigarette boxes, beer boxes, shoe boxes, milk cartons, plastic hollow panels, leather, fabrics, high strength aluminum foil and copper foil.

Corrugated box burst strength Tester standard:

ISO2759, GB/T 1539, GB/T 6545, TAPPI T810, JIS P8131, TAPPI T807

Inclined Impact Tester GT-N49

The Incline Impact Tester tests the ability of products to resist impact damage in actual environments, such as handling, shelf stacking, sliding motors, loading and unloading of locomotives, product transportation, etc.

Packaging tilt impact test standard:

ASTM D880, ISTA

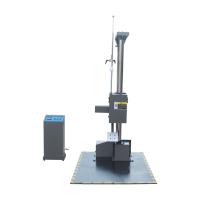

Packaging Carton Single Wing Drop Tester GT-LC05-1

The purpose of the single wing Drop Tester is to test the damage of product packaging and evaluate the impact resistance during transportation.

Carton drop test machine standard:

ISO 2248, JIS Z0202, GB/T4857.5, ISTA

-

JINGWEN JW-102C2Z paper Burst Tester$ 1556.00

-

-

-

-

-

-

-

-

- 1A complete guide to Dropping Tester types, applications and selection

- 2Bevel impact test for transport packages

- 3Vertical impact drop test for transport packages

- 4What are the factors that affect the bursting strength of carton cardboard?

- 5Why use an automatic Drop Tester?

- 6What are the packaging quality test methods?

- 7What are the standard test methods for hard packaging?

- 8How to check the drop resistance of the packaging box?

-

-

-

CHINA NBC-1050B Double drum Drop Tester$ 1139.00

-

-

-