What are the functions and benefits of ink friction testing?

Labels are important for all products, including safety and electrical products. Because labels contain important information, it is important that labels are durable and long-lasting. Ink wipe tests are routinely performed on all labels to ensure they are durable enough to stand the test of time. The benefit of ink rub testing is that it helps improve product safety, ensures compliance with international standards and provides long-lasting product value.

What is the Ink Rub Test?

The ink rub test is a test performed on a label whereby the label is rubbed against an abrasive. Maybe rub it hundreds of times, then check the readability of the label information on the label. Different liquids can also be used, such as alcohol, or even soap.

While the label is typically tested on devices where safety is important, any product label or even brochure can be rub tested. This test can be used for any critical application where it is important that the ink does not fade from wear.

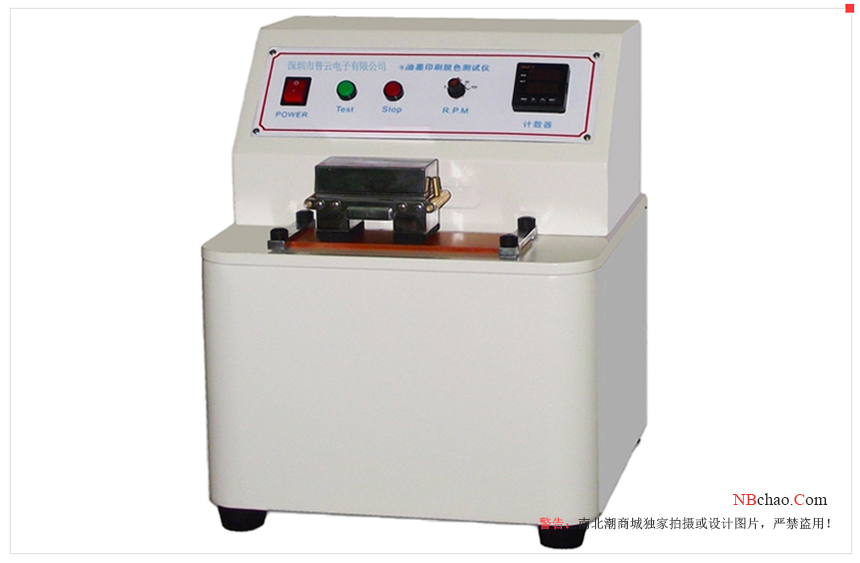

The ink rub test is performed on a dedicated machine. The results of the ink rub test are important to ensure that the product complies with recognized standards.

Improve product safety

One benefit of ink rub testing is improved product safety. Important product safety information is printed on the label. In machinery, labels contain information such as electrical ratings (voltage and amperage required), warnings, model numbers, and even basic instructions for use. These need to be visible for the life of the machine, or they could cause serious safety issues.

If this information is not readily available to the operator, a product security situation arises. This may create liability for the product manufacturer or user. An ink wipe test ensures that labels are durable and that due diligence has been done.

Standards compliant

Compliance with national and international standards such as IEC means that the importance of ink rub testing cannot be overemphasized. Meeting these criteria can be the difference between entering the market and failing in international purgatory. These standards are stringent when it comes to label durability.

UL has high standards when it comes to labeling and ensures that labels will not fade. It is understood that understanding product information is the first step in ensuring safety. That's why their standards require a certain amount of durability for product labels. This durability can only be demonstrated by performing an ink rub test.

increase product value

The benefit of third ink testing that cannot be ignored is that it enhances the value of the product. Putting a label on a product is a form of pride in doing a good job, much like the way a painter signs a painting. Part of the value of any product is its resale value. The high resale value is the real selling point.

When looking at a product, especially after a few years, a good, durable label is often seen as a sign of quality. An ink wipe test will ensure that a product's labels will last for the life of the product. This value-added feature comes with the product.

The ink rub test is a single method of demonstrating that your labels are durable and able to withstand the rigorous demands of the environment in which they will be used. It improves product safety, ensures compliance with standards, and increases product value. This is the right thing to do.

- 1Ink Rub Resistance Tester: Core Equipment and Application Analysis of Wear Resistance Testing for Printing Products

- 2Ink decolorization testing machine tests ink friction resistance

- 3GB/T36650 Optical Fiber Coloring Ink Performance Testing Scheme [With Instrument Parameters]

- 4Transfer phase of ink transport on the printing press

- 5Specific steps for ink adhesion selection

- 6Friction resistance of screen printing ink film

- 7What is the light resistance and chemical resistance of screen printing inks?

- 8Stickiness of screen printing ink

- 9What is screen printing ink thixotropy?