GB 1727 film general preparation method

1. Subject content and scope of application

This standard specifies the surface treatment of the base plate for the preparation of general paint films, the drying and state adjustment of the paint film, the constant temperature and humidity

conditions, and the thickness of the paint film, etc.

This standard applies to the preparation of test panels for the determination of general properties of paint films

2. Reference standards

GB 912 Technical conditions for ordinary carbon steel and low alloy structural steel sheet

GB 1736 Preparation method of insulating paint film GB

2520 Electro-tinned steel sheet and steel strip

GB 3186 Sampling of coating products

GB 3880 Aluminum and aluminum alloy sheet

GB 4871 Ordinary flat glass

GB 6741 Uniform paint film preparation method Spin Coater method

GB 9271 Color paint and varnish standard test panel

GB 9278 Temperature and humidity of paint sample state adjustment and test

Construction standard 25 Construction standard Asbestos cement pressure plate standard for electrical engineering

3. Materials and equipment

3.1. Materials

3.1.1 The tin plate

shall comply with GB 2520. The amount of tin plating is E4, the registered hardness is T52, and the thickness is 0.2-0.3mm. Unless otherwise specified, a test panel with a size of 25*120mm, 50*120mm or 70*150mm.

3.1.2 Glass plate

Unless otherwise specified, the glass plate shall meet the technical requirements specified in GB 4871. A test plate with a size of 90*120mm*(2~3)mm.

3.1.3 Steel plate

Unless otherwise specified, the steel plate shall comply with the technical requirements of GB 912 ordinary carbon steel. The size of the test plate is 50*120mm*(0.45~0.55)mm or 65*150*(0.45~0.55)mm.

3.1.4

Unless otherwise specified, the aluminum plate should meet the technical requirements specified in GB 3880. The test plate with a size of 50*150*(1~2)mm.

3.1.5 Asbestos cement board

Unless otherwise specified, the asbestos cement board shall meet the technical requirements stipulated in Construction Standard 25. The thickness of the test board is 3~6mm.

3.1.6 Steel rod

Ordinary low-carbon steel rod has a diameter of 13±2mm, a length of 120mm, a smooth surface at one end, and a hole or ring at the other end.

3.2. Equipment

3.2.1 PaintbrushWidth 25-35mm

3.2.2 Spray gunNozzle inner diameter 0.75-2mm

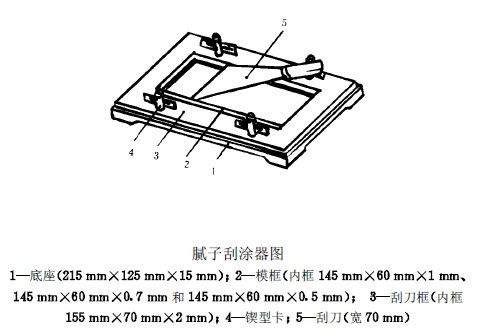

3.2.3 Squeegee applicator

3.2.31 The putty scraper, as shown in the figure, is composed of a model plate and a scraper, and there are 4 wedge-shaped cards on a smooth base to compress the scraper frame and the mold frame. Choose according to the putty thickness required by the product standard

3.2.3.2 Paint film preparer

3.2.4 ViscometerTu-4 viscometer or ISO Flow Cup

3.2.5 Lever micrometer or other paint Thickness Gauge

3.2.6 The scale of the stopwatch is 0.2S.

3.2.7 Drying boxDay blast constant temperature Drying Oven

4. Surface treatment of the bottom plateAccording to the provisions of GB 9271

5. SamplingAccording to the provisions of GB 3186

6. Board making method

Stir the sample evenly before painting. If there is skin on the surface of the sample, it should be carefully peeled off first. The multi-component paint is weighed and mixed according to the ratio specified in the product standard, and stirred evenly. If necessary, the uniformly mixed sample can be filtered with a 0.124-0.175mm (120-80 mesh) sieve, and then one of the following methods is used to prepare the paint film according to the product standard

6.1The brushing method

dilutes the sample to the appropriate viscosity or the viscosity specified in the product standard, and brushes it on the specified test plate quickly and evenly along the vertical and horizontal directions. Make it into a uniform paint film. Blanks or overflows are not allowed, and the painted samples should be dried according to the regulations in Chapter 7.

6.2Dilute the sample

to the spraying viscosity (at 23±2°C, the measured value in the Tu-4 viscometer, the oil-based paint should be 20-30s; the volatile paint should be 15-25s. In the ISO Flow Cup The measured value of the oil-based paint should be volatile paint should be 45-80s; or according to the viscosity specified in the product standard, and then spray on the specified test plate to form a uniform paint film without blank or overflow. Spray gun when spraying The distance

from the surface to be coated is not less than 200mm, the spraying direction should be at an appropriate angle to the surface to be coated, and the air pressure should be 0.2-0.4MPa (the air should be filtered to remove oil, water and dirt). Clause 7 specifies drying.

6.3 Dip coating method

Dilute the sample to an appropriate viscosity (so that the thickness of the paint film meets the requirements of the product standard), then immerse the test plate vertically in the paint solution at a slow and uniform speed for 30s and then take it out of the paint at the same speed. Put it in a clean place to drip dry for 10-30min, and hang the dripped sample or steel rod vertically in a constant temperature and humidity place or in an electric blast constant temperature Drying Oven to dry (the drying conditions are as specified in the product standard). If the product standard is for the first time

The drying time of the dipping paint is not specified and can be determined by yourself. But it does not exceed the drying time specified in the product standard. Control the drying degree of the first paint film to ensure that the paint film will not sag and bite or wrinkle after the second dipping. After that, the sample is turned upside down and dripped for the second dipping according to the above method, and dried according to the provisions of Chapter 1.

6.4 Scratch coating method

6.4.1 Putty scraping method

Put the test plate on the base of the putty scraper, put the mold frame and scraper frame with suitable thickness on it and clamp it tightly. Then use a metal scraper to evenly coat the putty on the test plate to make it into a uniform and flat putty film. Remove the putty sample and dry it according to the provisions of Chapter 7.

6.4.2 Paint film scraping method

Place the test plate on the platform and fix it. According to the thickness of the wet film specified by the product, choose a paint film preparer with suitable clearance. Place it at one end of the test plate, the long side of the preparer is roughly parallel to the short side of the test plate or placed on the specified position of the test plate, and then place an appropriate amount of sample evenly in front of the preparer. Hold the preparer with a certain downward pressure and at a constant speed skating the test plate to the required thickness

Wet film. Preparation method of uniform paint film Rotary lacquer coating method shall be carried out in accordance with GB 6741

6.5 Casting method

Preparation of paint film according to the provisions of GB1786 Chapter 4

During the plate making process of the above methods, direct contact between the fingers and the surface of the test plate or the surface of the paint film is not allowed, so as not to leave fingerprints that affect the test of the performance of the paint film.

7. Drying and condition adjustment of paint film

7.1Unless otherwise specified, the paint film prepared according to the method specified in Chapter 6 should be placed flat under constant temperature and humidity conditions, and dried according to the time specified in the product standard. Unless otherwise specified, self-drying paints are generally adjusted for 48 hours (including drying time) under constant temperature and humidity conditions, and volatile paints are adjusted for 24 hours (including drying time), and then various performance tests are performed.

7.2 Drying paint

Unless otherwise specified, the paint film prepared according to the method specified in Chapter 6 should be placed at room temperature for 15-30 minutes, and then placed flat in an electric blast constant temperature drying box to dry according to the temperature and time specified in the product standard. .

Unless otherwise specified, the dried paint film is adjusted for 0.5-1h under constant temperature and humidity conditions, and then various performance tests are carried out

8. Constant temperature and humidity conditions

Unless otherwise specified, constant temperature and humidity conditions shall comply with the provisions in

9. Paint film thickness

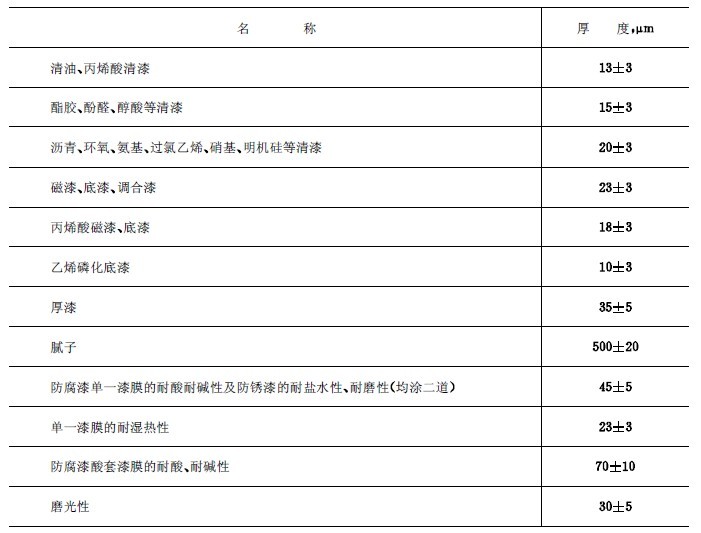

Unless otherwise specified, the thickness of various paint films after drying is specified as follows:

Additional Notes

This standard was proposed by the Ministry of Chemical Industry of the People's Republic of CHINA.

This standard is under the jurisdiction of the National Paint and Pigment Standardization Technical Committee.

This standard is drafted by Harbin Paint Factory.

The main drafter of this standard is Zhang Bingli and Yang Mingyu.

- 1Polyurethane-graphene composite prepative film

- 2Thin layer chromatography, TLC method for preparing PLA film

- 3What are the main differences between Mayer Rods and doctor blade Applicators?

- 4How to measure the viscosity of paints with ISO Flow Cup?

- 5Why choose nbchao for experimental film instrument procurement?

- 6Why does the appearance of the paint film wrinkle, bleed and change color?

- 7Characteristics of alkyd paint

- 8How to choose these experimental coating equipment?

- 9What is the difference between a frame prepper and an I-type prepper?

蜈蚣 - 《南北潮商城》