Gypsum board for paint thickness measurement

DeFelsko manufactures handheld, non-destructive ultrasonic coating Thickness Gauges that are excellent for non-destructive measurement of dry film thickness of paint on plasterboard (drywall/stone/wallboard).

Figure 1 The PosiTector 200 B1 measures the total thickness of a single coat of paint and primer.

Drywall is usually painted with 3 coats of paint (one primer and two coats of paint). Traditionally, destructive testing methods have been used to determine paint thickness. Today, the primary purpose of ultrasonic testing is to non-destructively measure the total thickness of a coating system, typically in the range of 3 to 5 mils (75 – 125 μm). Other challenges include the tendency of the primer to absorb into the drywall paper film, the effect of paint surface roughness or texture, the measurement effect on joint compound and the possible need to measure individual paint or primer layers.

Both models are excellent choices for drywall.

1. The PosiTector 200 B1 (standard model) is an economical, commonly used solution for measuring total coating thickness systems.

2. The PosiTector 200 B3 (advanced model) is capable of measuring the total coating thickness and the individual layer thickness of up to 3 layers in a multi-layer system. It also has a graphical mode for detailed analysis of coating systems

Measurement application:

1. Measure the total thickness of the paint system using the basic PosiTector 200 B1

2. Measure on a textured surface

3. PosiTector 200 B3 graphics function

4. Working with Surface Textures

5. Measure joint compound

6. Ultrasonic multi-layer function

additional terms:

how to measure

graphics mode

Other measurement methods

Background of drywall paint

Why measure with ultrasound?

Application 1: Measuring Total Thickness

For those familiar with magnetic coating Thickness Gauges, using an ultrasonic coating Thickness Gauge is simple and intuitive. The measurement method is simple and non-destructive. The displayed result is the total thickness of the coating system (primer + paint layer).

The PosiTector 200 B1 can instantly measure most drywall paint applications. With a measurement range of 13 to 1000 microns (0.5 to 40 mils), it is an excellent choice for measuring the overall thickness of coating systems. The basic version of the instrument is adjustable for most applications without calibration, is mil/micron switchable, and features a large, thick, impact-resistant Lexan display.

Gypsum board presents two distinct substrate surfaces: the panel paper of untreated wallboard siding, and the tape compound over joints, corners, and fasteners (screws or nails) . The measurements of the PosiTector 200 B1 do not require any special adjustments.

Both PosiTector 200 models feature a large LCD made of thick, impact-resistant Lexan.

Some walls have coating systems that have been applied in many layers over the years. When the applicator only needs to know the final total thickness of the coating system, our PosiTector 200 B1 is the ideal solution. Since the primer coat is thin and mostly absorbed by the substrate, it has little effect on the total thickness measured.

Application 2: Measurements on textured surfaces

Some painted wall surfaces will have a slight surface texture from the applicator roller (see Figure 3).

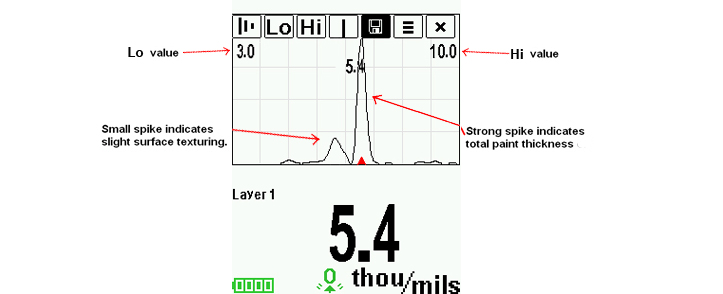

Figure 3 Measurements taken on a textured surface.

On textured or rough surfaces, the PosiTector 200 will typically identify the thickness from the coating peak to the substrate. This is represented by distance #1 in Figure 4. A couplant fills the gap between the probe and the coating to help the ultrasonic pulses enter the coating.

Figure 4 Couplant fills the gap between the probe and the coating.

Sometimes this surface roughness causes the gauge to show a lower thickness value (distance #2). This happens because the couplant/coating interface is more echogenic than the coating/substrate interface. The positioner 200 has a unique user-adjustable SET RANGE feature (see Figure 5) to ignore roughness echoes.

Lo sets the minimum thickness limit and Hi sets the maximum thickness limit. In this range, the measured thickness is 3.3 mils.

The more advanced PosiTector 200 B3 model provides additional information about surface texture, as described below.

Application 3: Using PosiTector 200 B3 graphics capabilities

The advanced model called PosiTector 200 B3 is capable of measuring the thickness of the entire coating system as well as up to 3 individual layer thicknesses in multi-layer systems. It also features graphical readouts for detailed analysis of coating systems.

The gauge's large LCD display is capable of displaying both numerical and graphical representations of measurements. The graphic display can be set to appear on the right side of the screen. It shows a graphical representation of an ultrasonic pulse as it travels through a coating system.

Surface texture:

Some painted wall surfaces will have a slight surface texture from the applicator roller (see Figure 3).

Figure 6 Open the graphical display of the B3 model.

In the screen capture (Figure 6), the graphic display clearly identifies the total paint thickness by showing the strongest echo from the ultrasonic pulse. The instrument's graphical display may provide additional information. In this example, it indicates the amount of surface texturing.

Joint compound:

When taking a total thickness measurement, the gauge will show periodic high readings when it encounters the joint compound covering the drywall joints. The resulting measurement will include the thickness of the joint compound in its total thickness calculation. This is due to the density difference between drywall and joint compound being greater than the difference in density between joint compound and primer. By changing to 2-coat application using the gauge menu, the gauges will identify the total paint thickness and joint compound thickness separately.

Multi-layer function:

The multilayer measurement capability of the PosiTector 200 B3 also has the potential to identify the thickness of individual paint layers, but this will be application specific as the gauge is limited by the difference in sound velocity between the primer and paint layers. At least each layer of paint can be measured separately as it is applied, allowing the user to calculate the thickness of the most recently applied layer.

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge