How to adjust the thickness of the scraper coating film for the laboratory small coater?

The laboratory small coating machine can choose a wire rod or a scraper to coat the film. The wire rod is relatively simple. The thickness of the coating film of the wire rod is fixed, and the thickness of the film that can be scraped by a wire rod is constant. But there are two types of scrapers, one is a wet Film Applicator with fixed film thickness, and the other is an adjustable scraper coater. Generally, for samples with relatively large particles and relatively high viscosity, a scraper is preferred, but for samples that need to be scraped and coated with various film thicknesses, an adjustable scraper is often more cost-effective.

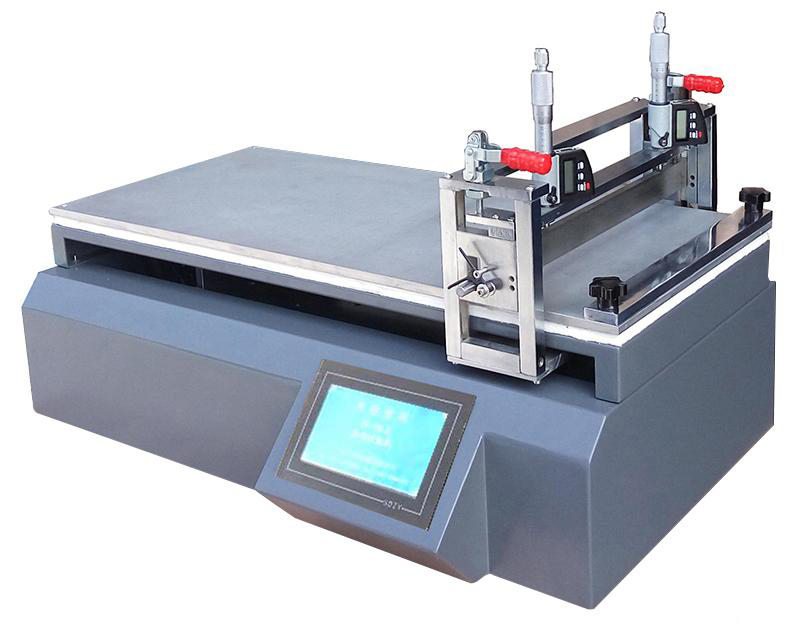

So how does the adjustable scraper on the small coater adjust the thickness of the coating film? This article takes a domestic coating machine as an example. The adjustable scraper is adjusted and controlled by a micrometer regulator.

This adjustable knife coater is controlled by a differentiator to control the film thickness. So first, let's understand how differentiators are used. There are only two buttons on the differentiator, one is the switch key, and the other is the unit conversion key. In addition to the switch, the switch key can also be zeroed by long press. The unit conversion key is mainly used to convert the units of mm and inches.

In addition, there is a knob on the differentiator, the small part at the top and the thick white part in the middle. The small part is used to adjust the scraper height in a large range, while the thick white part in the middle is used to adjust the specific decimal point value. The "SET" button above is both an on-off key and a zero-adjustment key. And the ABS/INC button next to it is to convert the thickness unit.

After knowing the differentiator, let's take a look at how the scraper coater controls the thickness of the scraper.

1. Tighten and fix the micrometer differentiator with screws , and place the coated substrate.

2. Put down the pressure rods at both ends and press the coated substrate tightly.

3. Adjust the differentiator to zero first, and then turn the two knobs clockwise to adjust the gap between the scraper and the substrate (that is, the thickness of the coating film). First turn the black knob on the top clockwise to adjust the coating thickness in a wide range, and then turn the white knob in the middle to adjust the value of the last digit.

4. Make sure that the scraper is kept in a horizontal state. If necessary, you can use a level to determine it, so that the film produced by scraping is uniform as a whole.

The above are the detailed steps of adjusting the adjustable blade coater before coating.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater