What are the different performance tests in the automotive industry?

The automotive industry is growing exponentially. Competition among automakers has intensified as more and more brands jump on the bandwagon. Much has changed in the way cars are built and designed today. Parts are imported from various places and assembled in one place. In fact, assembly is done with as little human interference as possible. Everything is controlled by high-end computers. The assembly line is actually a very fascinating place to be.

Beyond that, every vendor is extremely cautious about industry standards. Because human safety is at stake. On the one hand, manufacturers dismiss shipments that do not meet specifications. On the other hand, the supplier is worried that his production cost will be affected by the rejection. Also, what matters is reputation and relationship with customers. That's why, quality and timely delivery are the keys to success for automotive suppliers. In order for the quality to meet expectations, suppliers often carry out certain mandatory tests.

Salt spray test

Every part made of metal is subjected to a salt spray test. In this test, the sample is exposed to a salt mist for a certain period of time and its behavior is observed under these conditions. This test determines the corrosion resistance of the samples. Under actual operating conditions, the heat in which automotive parts are exposed to different environmental conditions can induce corrosion. To protect the metal from this, there is a coating on the metal parts. This coating is either paint or electroplating. The effectiveness of these protective layers is evaluated by this test. The samples with the desired coating were placed in the Test Chamber and their reactivity with NaCl mist was evaluated by visual inspection.

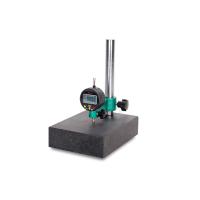

cupping test

This test is used to check the performance of body paint coatings. Due to physical impact, the bodywork is sometimes dented and can chip the paintwork. A cupping Tester is a small test instrument, but it can tell you a lot about the paint coat and sometimes the condition of the sheet metal. Combined with the tensile properties of metal plates, the elongation properties of coatings are tested. In this test, a metal sample coated with paint of the desired quality is held in a fixture. It has a punch that is moved forward with a rotating handle. When the operator turns the handle, the punch moves from its position and begins to move towards the sample. The punch will continue to move until it deforms the sheet metal. Cupping will be measured with a dial gauge. It is also important to visually inspect the performance of the paint. In a good coating, the sheet metal will crack without the coating coming off. Whereas in inferior paint, the paint becomes flaky due to the deformation of the sheet.

Stretching test

Literally any automotive component can be tested for tensile properties. But the tensile test is done according to industry requirements, like you don't need to do a tensile test on taillights or headlights. Can be used on tires, door seals, sheet metal, fiberboard, seat fabrics, steering covers, wires and more. It evaluates the performance of materials when subjected to external forces.

Color matching test

In a car, aesthetics are very important, regardless of the class of the car. From the color of the dashboard to the color of the handlebars, everything needs to be in sync throughout the production line. In fact, in terms of vehicle lighting, relevant departments have formulated strict standards. The color of the tail lights shall not deviate from the prescribed color. The biggest rejections automotive suppliers face are due to color mismatches.

Thickness test

Everything needs to be engineered to design and specification. Thickness measurement is very important for airbag manufacturers. They should be designed so that upon impact to the sensor's critical force, the airbag module should rupture. If the groove of the airbag module is too thick, it will not allow the airbag to inflate when required. If the airbag is too thin, it will inflate in a crash.

weathering test

Vehicles provide better performance in any situation, and users would never expect their colors to fade when parked in an open car park, or the bodywork to corrode when its metal parts are exposed to rain. In order to obtain satisfactory performance, the samples were subjected to a cycle test with an aging Test Chamber under 5 different climatic conditions. Heat, rain, condensation, UV rays and humidity.

For more information about automotive testing equipment, such as cupping Testers, weather chambers, salt spray chambers, etc., please contact us at NBCHAO Mall.

- 1Application, Principle Introduction and Precautions for Selection of Pipeline Thickness Gauges

- 2Principle, Characteristics and Application of FISCHER Coating Thickness Gauge

- 3Working Principle and Application Analysis of Ceiling Salt Spray Tester

- 4Salt Spray Tester in salt spray testing

- 5Hardware salt spray test method

- 6Purpose and method of durability testing of building materials

- 7Test Scheme for Temperature and Moisture Resistance of Packaged IC Chips

- 8Application of Film Thickness Gauge in automobile paint thickness measurement

- 9Paint layer Thickness Gauge unknown selection skills