How to properly maintain the high shear disperser?

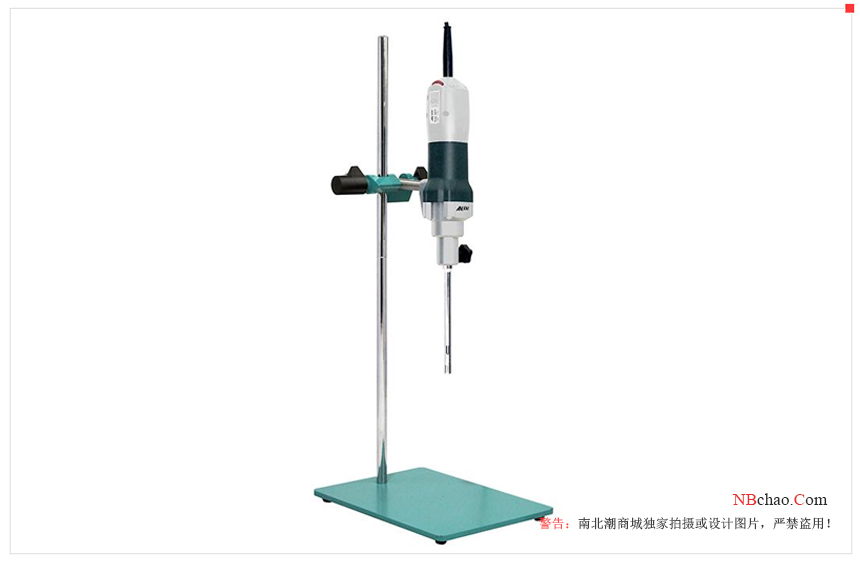

A disperser is a type of mixer in a broad sense. Due to the use of a high-speed stirrer (such as a sawtooth disc stirrer), a strong turbulent flow can be formed locally, and it usually has a strong dispersion and emulsification effect on the material. Therefore, this type of high-speed mixer is also called a disperser. The dispersing machine is mainly divided into lifting dispersing machine and kettle dispersing machine. The lifting dispersing machine can be divided into hydraulic lifting dispersing machine, pneumatic lifting dispersing machine, hand lifting dispersing machine, etc. according to the lifting method.

The high-shear dispersing machine adopts various specifications such as electromagnetic speed regulation, frequency conversion speed regulation and three-speed, and the operation is stable and powerful, suitable for various viscosities; hydraulic and mechanical lifting forms, lifting and rotating freely, suitable for various positions; ordinary and explosion-proof Configuration, safe and reliable, simple operation and maintenance; strong production continuity, rapid dispersion and dissolution of materials, good dispersion effect, high production efficiency, stable operation, and easy installation. According to the viscosity and processing capacity of different materials, there are different powers and models.

Main items for maintaining high shear disperser

1. The V-belts of the high-speed disperser should be equal in length, put them into the transmission box, tighten them properly, tighten the bolts of the slide plate, and cover the upper cover.

2. If the equipment of the high-speed disperser is not used for a long time, the power supply must be cut off, all cleaned, and all lubricating parts should be filled with oil, and the main shaft and oil cylinder should be oiled to prevent rust.

3. The oil tank of the high-speed disperser uses 46# hydraulic oil, which is replaced and cleaned every six months. The filter screen is cleaned once a month, and cleaned once within two or three days after oil change.

4. The gears, bearings, balls, shafts, bushings and oil cylinders of the rotating part of the high-speed disperser should be oiled once a week. If overheating or abnormal noise is found during use, it should be checked in time.

5. If the thermal relay of the high-speed dispersing machine stops due to overload, you need to press the "reset" button of the thermal relay to continue the operation.

6 The AC contactor of the high-speed dispersing machine is inspected every six months, and the equipment is overhauled once a year.

7. The dispersing machine of the high-speed dispersing machine regularly checks the wearing parts of the dispersing machine, such as bearings, oil seals, etc., and replaces them immediately if any wear is found.

8 The high-speed disperser needs to touch the pot of the disperser to check once a day, and make a record of touching the pot carefully.

9 When the diameter of the blade of the high-speed disperser is D, the diameter of the container is 3.4-3.9D, the height of the blade from the ground is 0.5-0.7D, and the filling height is 2.4-3D, which can achieve a good dispersion effect.

10 The column and stirring shaft of the high-speed disperser need to be lubricated regularly, usually once per shift.

11 Check the transmission V-belt of the high-speed disperser irregularly.

After reading the whole article, do you have a certain understanding of Weihua High Shear Disperser? If you have any questions about the high shear disperser, please consult our company.

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Several Common Coating Dispersers

- 3Inspection Contents of Chemical Plant Disperser

- 4The difference between Disperser ordinary and explosion-proof type

- 5Disperser stirring speed formula

- 6What's wrong with Disperser stirring?

- 7Main Structure of Vacuum Defoaming Disperser

- 8What oil is used in Latex paint Disperser?

- 9How to make a Disperser bucket holder?