Common problems and countermeasures of film coating

Labs often encounter operational difficulties when coating films on thin films. On the one hand, it is difficult to fix the flatness of the coating film due to the thin and soft substrate. On the other hand, it is difficult to control the pressure of the coating film and the speed of scraping the material. Inhomogeneity, it often takes a lot of energy for researchers to prepare an exquisite membrane. Therefore, laboratory researchers are increasingly favoring the use of automatic film coating machines to make films. But there are some problems that follow, which may be a headache for everyone:

1. How come there are still scratches when the sample is scraped by a film coating machine?

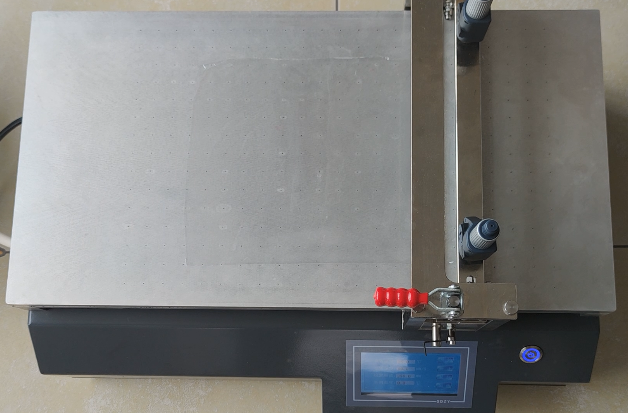

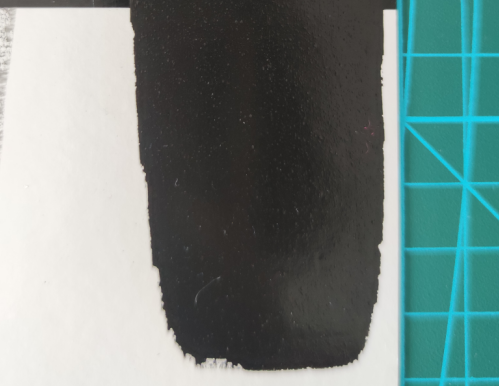

Reason: The first factor of this problem is to consider the fineness, assuming that the sample fineness is 20μm, and the height difference of the Film Applicator you prepared is only 10μm, no matter you use a scraper or a wire rod, the large particles will be scraped off, resulting in scratches. The case shown in the figure below (the customer’s fineness is more than 30 μm, and a 1.5 μm wire rod is used for scraping)

1.5 μm stick coating effect

Obvious graininess after scraping with 80μm rod

Another factor is to doubt the accuracy of the Film Applicator. Good products are not cheap, and cheap products are not good. Not much to say.

The last reason is the roughness of the substrate, if the roughness is too large, it will also affect it.

Solution: Grind the sample as much as possible to ensure that the fineness is below the nominal fixed film thickness of the preparer. If there are still scratches, consider the second and third reasons.

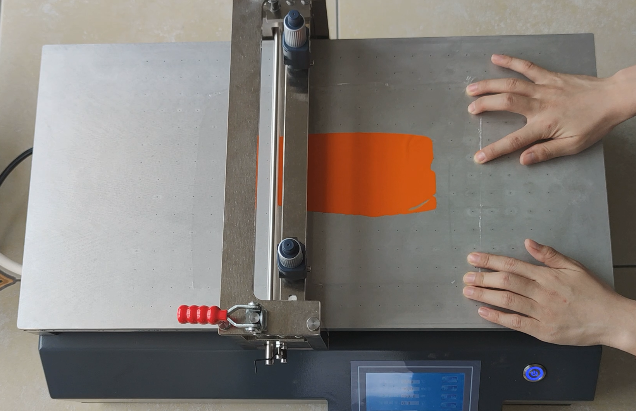

2. Vacuum adsorption is also difficult to absorb and smooth, and there will be waves in the ultra-thin film thickness

As shown below:

Reason: This phenomenon often occurs on film, and paper is relatively rare. The reason is that the vacuum adsorption holes are arranged regularly, the adsorption holes are firmly adsorbed on the line, and the ones away from the adsorption holes are relatively less firm, resulting in a wave-like phenomenon.

Solution: The thinner film is coated with the thinner film layer, and the thinner and denser vacuum plate is selected. Adjust the adsorption pressure well. The other is to advance a piece of paper or glass plate through the coating area in the middle of the film to ensure that the surrounding film can be adsorbed to the vacuum plate, and just flatten the film in the coating area on the paper/glass. This method of operation is relatively easy to implement in the laboratory , it is recommended to use. Because theoretically all adsorption is impossible to be very good, but just make sure that the coating area is flat, don't get too tangled. The film has a certain degree of adhesion, and it is easy to cause wrinkles on the film if you are not careful. You can use soft materials to polish the skin without damaging the surface as much as possible. Be careful not to stain the surface with oil, especially if you are not used to grinding with your hands. Otherwise, the oiled area of the sample will not be able to adhere due to surface tension problems, and the film will be scrapped.

- 1NVP anode film FAQ and solution

- 2Application of laboratory coater in LED fluorescent film Spreader

- 3Application of Automatic Film Applicator in preparing fluorescent diaphragm

- 4Brief analysis of the preparation technology of ionic liquid polymer composite electrolysis and anode pole piece

- 5Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- 6Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]

- 7Experimental Application of Automatic Film Applicator on Glass substrates

- 8Experimental Application of Automatic Film Applicator for Coating Hot-melt adhesive on Breathable Film

- 9Study on Experimental Technique of Scraper Automatic Film Applicator Coating Adhesive on Film