Influence of impeller structure of high-speed disperser on rheological properties of coatings

Cast coating is a mixture of liquid phase and solid phase materials. When the suspending agent in the system components fully exerts its effect, the solid phase aggregate is fully dispersed in the liquid phase carrier to form a network-like three-dimensional structure. To achieve this goal, the stirring and dispersing process of the coating is very important. In the high-speed disperser, the agitator-impeller is its core component. According to the flow form of the fluid, the impeller can be divided into two types: axial flow and radial flow. The impellers with different flow patterns have a very direct impact on the stirring effect of the high-speed disperser.

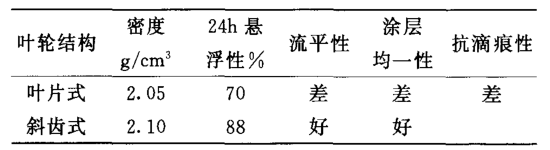

Every fluid has its rheological properties, and many technological properties of casting coatings are the specific performance of its rheological properties. In order to fully understand the influence of different forms of impellers on the rheological properties of coatings, two typical impellers with structures are selected here: vane-propelled impeller and helical-toothed radial impeller, and alcohol-based coatings are prepared respectively. The coating ratio/% (parts by mass): zircon powder 100, suspending agent 3-4, binder 2-3, solvent 30-40, and test its various technological properties, the results are shown in Table 1.

Table 1 coating process performance test results

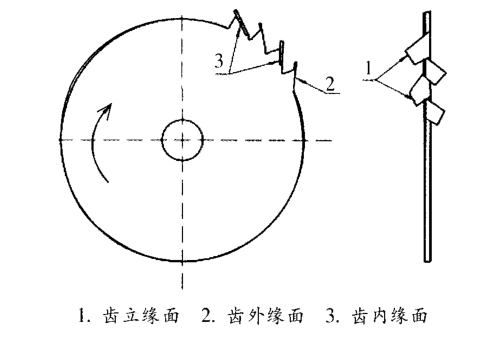

It can be seen from Table 1 that the various process performances of the paint prepared by using the helical radial impeller are significantly better than that of the blade propulsion impeller. The structure of the helical radial impeller is shown in Figure 1. The upper and lower teeth are alternately bent on the edge of the impeller. Type, its inclination angle is 20°~40° along the tangent direction, the vertical edge surface of each tooth can produce strong impact; the outer edge surface of the tooth pushes the material to flow outward to form circulation and shear force, and a part near the upper tooth The material decelerates inward and slides over the inner edge of the tooth, which intensifies the shearing effect. When the paint circulates to the vicinity of the helical tooth, it is continuously accelerated and decelerated, resulting in a good dispersion and shearing effect, so that the mixed paint can be well processed. Performance, that is, it has the rheological properties to meet the requirements of the mold coating. However, when the blade-propelled impeller is stirring, the material is sucked from the top of the blade to the bottom, discharged in a spiral shape, and forms an axial flow. The degree of turbulence of the material is not high, and the shearing effect is not large, but the circulation is large, so it is not necessary. It is suitable for liquid-solid phase dispersion system, which is consistent with the test results of the technical performance of the prepared coating.

Fig.1 Schematic diagram of helical radial impeller

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Briefly describe the difference between High Speed Disperser and Homogenizer

- 3Several Common Coating Dispersers

- 4Inspection Contents of Chemical Plant Disperser

- 5The difference between Disperser ordinary and explosion-proof type

- 6Disperser stirring speed formula

- 7What's wrong with Disperser stirring?

- 8Main Structure of Vacuum Defoaming Disperser

- 9What oil is used in Latex paint Disperser?