How to choose a good latex paint?

For interior wall latex paint, styrene-acrylic emulsion, vinegar-acrylic emulsion, vinegar-tert emulsion and vinyl acetate-ethylene copolymer emulsion can generally be used. Styrene-acrylic emulsion and vinegar-acrylic emulsion are widely used in CHINA. The price of vinegar-acrylic emulsion is moderate, and the ability of styrene-acrylic emulsion to bind pigments is high.

For exterior wall latex paint, silicone-acrylic emulsion, pure acrylic emulsion, styrene-acrylic emulsion, and vinegar-tert emulsion can all be selected. Styrene-acrylic emulsion is currently the most used in CHINA, because its cost performance is easy to be accepted by people.

For some special latex products, such as matching latex wood coatings with properties no less than conventional acid curing, nitro and polyurethane series, from sealers to glossy or matt varnishes and paints: aminoacrylic latex baking varnishes, including coils Industrial paints including paints; Glossy latex door and window paints with gloss similar to alkyd paints but better durability, and rich in pressure resistance and viscosity: suitable for general bridges, towers, large oil storage tanks, etc. A complete set of anti-corrosion latex paint for alkyd series, such as epoxy acrylic latex paint, including primer and top coat, etc. There are also mature products for selection abroad.

Glass transition temperature, minimum film-forming temperature, average particle size and particle size distribution are quantitative indicators that affect the selection of polymer emulsions. For example, glossy latex paints generally use Tg. The higher the emulsion, the smaller the average particle size of the emulsion, the better the bonding ability of the pigment filler. But what really determines the choice of emulsion is often some qualitative and quantitative indicators or factors that are not directly expressed in the instructions. For example, the composition of the polymer, the residual monomer content, the effect of the emulsion on the film gloss, adhesion, physical and mechanical properties, and indoor and outdoor durability, etc. Some of these indicators or factors are kept secret by the manufacturers and are difficult to provide, and some of them have too many factors affecting the formula and cannot be simply quantified. However, a comprehensive digestion of product instructions, especially their formula examples, including communication with the technical staff of the emulsion supplier, coupled with your own accumulation of knowledge on polymer emulsions, will allow you to more accurately select those who are qualified to enter your screening process. alternatives, and then determined through experimental comparison. For example:

Spread the emulsion on a glass plate, place it at (50±2)°C for 4 hours, observe the transparency of the emulsion film, the more transparent the better.

Soak the above-mentioned glass plate in distilled water, and observe the time required for it to appear white. The longer the time, the better the water resistance. This can be used to choose the emulsion for real stone paint.

The selection of emulsion for exterior wall latex paint can also pass the whitestone test (whitestone test). The so-called white stone test is to prepare latex paint with white marble chips as filler. White marble chips are easy-to-color particles. After artificial accelerated aging or natural exposure, it is easy to identify, so as to determine the performance of the emulsion. A test method.

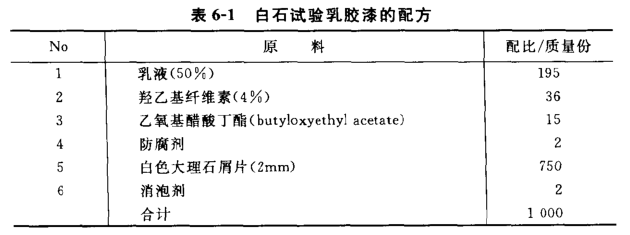

The formula of Shiraishi test latex paint is listed in Table 6-1.

The Shiraishi test latex paint was tinted with 0.03% phthalocyanine blue. Tests show that 0.03% phthalocyanine blue has negligible effect on emulsion test.

White marble shavings are chosen for the first reason that when the blue emulsion film is pulverized and peeled off, the white marble will be displayed and easily identified;

Ethoxybutyl acetate was added to avoid differences in drying times.

It can be tested by coating Shiraishi test latex paint on the fiber cement board.

According to reports, using the Shiraishi test method to evaluate the photochemical stability of polymer emulsions can shorten the test time by 4 to 5 times compared with natural exposure. The Whitestone test shows that if a polymer emulsion shows visible degradation after only 6 months, the emulsion should not be used in emulsion-rich formulations such as gloss paints and varnishes.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets