Characteristics and Applications of Synthetic Paper

Synthetic polymer film is different from natural fiber paper in many ways. First, it is not stiff (hard enough); second, because it has no porosity, it is impossible to absorb ink like paper. Of course, they also have characteristics. Such as good chemical resistance, folding resistance , good toughness, continuous folding resistance, and smooth surface, which can print better prints, etc.

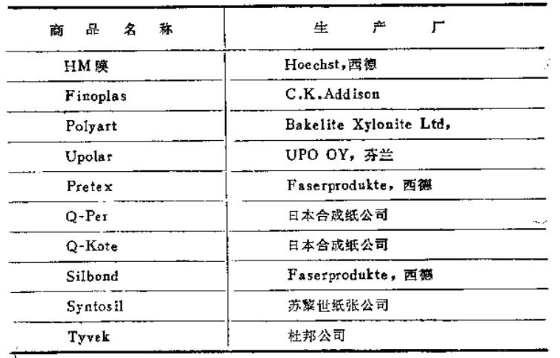

For synthetic paper, opacity, color, surface gloss, printability . Opacity is generally obtained by adding titanium dioxide and fillers (such as kaolin, calcium carbonate, etc.) to synthetic paper. The Q-Kote synthetic paper in the table is opaque after surface coating.

The products in the table are produced by two-way drawing (extension) or similar processes . Among them, Polyart synthetic paper is a representative variety produced in the early stage. It is a high-density polyethylene film containing fillers. It has the characteristics of good whiteness, good gloss, smooth and non-absorbent surface. As long as you pay attention to control, it can be applied to various printing method. Although it is less absorbent and absorbs less ink, under proper conditions, a small amount of oil can also get good results. This is because the natural plant fiber paper will absorb more ink, and due to the light diffusion effect of the fiber, the effect of the pigment will be reduced, so the gray level of the printed product will be increased, thereby reducing the effect of the printed product.

In order to obtain good printing adaptability of synthetic paper, it is necessary to pay attention to controlling the surface properties of high-density polyethylene film. Generally, synthetic paper can get better adhesion fastness to oiler after being treated with electric charge.

The disadvantage of this kind of paper is that it is more expensive (2-3 times more expensive than ordinary paper), the printing requirements are relatively strict (especially in flat printing), and the ink fastness and dryness requirements are relatively high. Of course, since synthetic paper is mixed with a large amount of fillers, its surface condition is much superior to that of polymer (plastic) films, so the requirements for ink fastness and dryness are lower than those of plastic films. .

Due to its good fastness and folding resistance, synthetic paper is mostly used in areas that require a long service life, such as maps, labels, book covers, etc., and the price will not bring any problems to these areas. Of course, their scope of application is constantly expanding.

-

-

-

PUYUN PY-H619 inks Absorption Tester$ 3830.00

-

- 1Application of Manual Ink Proofer

- 2How to calculate flexo ink consumption?

- 3Keep your screen printing customers happy with accurate printing colors

- 4Maintain your screen printing quality with proper screen tension

- 5Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 6Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

向华,龚逸仙,李军,林木雄,欧建志 - 《《用于塑料薄膜的荧光凹印油墨的制备与性能研究》》

- 7What faults are prone to photogravure printing? What remedies are there?

- 8The conveying phase of the ink conveying on the printing machine

- 9Distribution phase of ink transport on the printing press