The relationship between paste ink and viscosity (viscosity)

Viscosity is a measure of the internal friction of a fluid. However, if dispersed species are present in the fluid, the viscosity of the fluid changes.

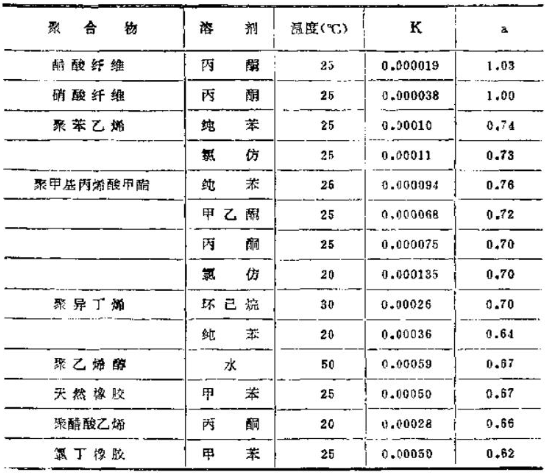

Generally speaking, for the same pigment system, the greater the viscosity of the binder used in the ink, the greater the viscosity of the ink. For the same binder system, if the amount of pigment (or filler) is more, the viscosity of the ink will be greater. The larger the original particle size of the pigment (or filler), the smaller the viscosity of the ink. The better the dispersibility of the pigment (or filler), the lower the viscosity of the ink.

Therefore, the plastic viscosity of the ink can be considered from the viscosity of the binder and the concentration of the pigment (or filler).

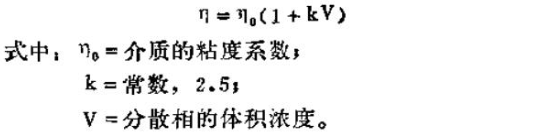

In 1906, Einstein derived a formula for the viscosity of dispersed suspensions:

In the derivation, he put forward several assumptions: (1) The particle is spherical; (2) The particle itself is a rigid body; (3) The number of particles in the system is not large, and they will not affect each other in the flow; (4) There is no turbulence Phenomenon.

According to the above assumptions, it can be seen that the particles cannot react with the liquid, and the particles do not interact with each other. This is a formula for predicting the viscosity of a dispersion based on the concentration of the simple dispersed phase. It can be seen that the ink dispersion does not obey Einstein's law, because (1) the pigment (or filler) particles are not all spherical rigid bodies; (2) the ink is a relatively thick and thick dispersion system; ( 3) Particles and linking materials can interact with each other; (4) Particles can interact with each other; (5) The dispersion is abnormal due to shearing.

The interaction between the particles and the linking material is caused by the non-flow effect of the linking material on the wheat flour of the pigment particles and the absorption of the linking material by the pigment. When the applied force is large enough to break the absorption bonds, the system has a pseudoplastic viscosity property. This effect is more pronounced at low shear rates, because the absorption bonds become very weak due to the increased distance from the particle surface. weak reason. The particle-particle interaction is due to the stagnant action of the binder in the interstices of the aggregated particles. It can also lead to pseudoplastic viscous properties if shear action can reverse the destruction of aggregated particles. This pseudoplastic viscosity can also be caused by the distortion of the liquid (fluid) body after shearing or the alignment of non-hard particles (or non-spherical particles).

Based on the above situations, we can basically know that the viscosity of the paste ink mainly depends on the viscosity of the continuous material used and the amount of pigment (or filler).

As for the viscosity of the ink, since it is basically proportional to the viscosity (but not necessarily), the situation is relatively simple.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions