What causes printing ink to fly or atomize?

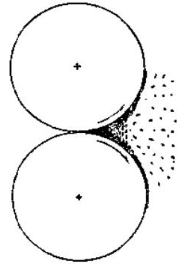

It should be assured that the ink will not be thrown from the ink spokes of the printing press by centrifugal action. Fogging is caused by the separation of the ink film, which is not due to the flow of the fluid (ink), but due to rupture. As the ink separates on the two rapidly rotating ink sets, it pulls the oil film out of the filaments and breaks. Due to the breaking effect, the ink filament will be broken irregularly into two equal parts, so the breaking position is generally not in the center. If the fracture of the filament occurs in more than two places, the broken part in the middle will be released due to the withdrawal (retraction) of the rest, forming a round and small sphere with surface tension, as shown in the figure. If these small spheres cannot be taken away by the rotating stick, they will exist in the form of free ink droplets and be ejected by the printing press. Therefore, the flying ink of the ink is caused by the multi-phase breakage of the ink filaments at the same time, which is caused by the droplets flying away from the printing machine.

Ink flying phenomenon when the ink filament breaks on the rotating ink roller

In 1935, it was discovered that the ink droplets flying off the printing press had both positive and negative charges.

When water is dispersed into very fine particles to form a gas phase, the water droplets are positively charged, and the corresponding part of the air is negatively charged.

The separation of charge needs to be attributed to the electrical double layer turned by the fragmented outer liquid film that appears in the ink filament and ink drop interface . Due to the separation of charge, these thin liquid layers are destroyed, and some remain in the The corresponding negative charge in the ink dissipates in the air, which is called Ballo-Electricity.

The retracted part of the broken filament will carry the charge to the ink roller or the rotating web. Several charged ink droplets formed after multiple fractures on the filament are expelled to the space due to the partial electric charge on the ink series surface, so that they cannot be adhered (attached) again. The ink from the printing press is mixed. As a result, the ink droplets are scattered in the air.

Due to electrical repulsion, the expelled charged particles have little tendency to associate together. The relatively small charged particles may be blown into mist.

It can be seen that there are many factors for Feimo, both internal and external. The external cause is the charge. The large amount of charge on the particles mainly depends on the separation rate of the ink film due to the printing speed. In addition, temperature and humidity are also very important factors.

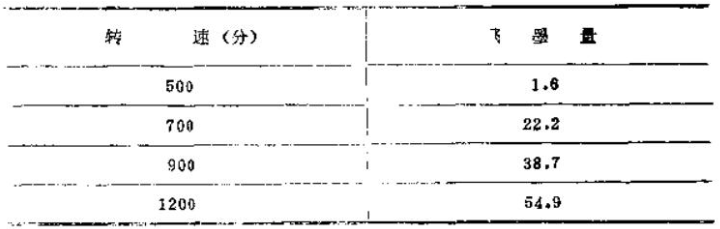

As can be seen from the table, printing speed is the most important factor. An ink that flies ink at high speed printing may not have ink flying at low speed. Generally speaking, as far as newspaper printing is concerned, at a speed of 1000 ft/min, ink misting is very serious.

When the absolute humidity is relatively low, more charges can be generated, so the cold and dry climate will increase the phenomenon of ink flying. Increasing the viscosity of the ink can also reduce the generation of charge. If the room temperature is relatively high, the misting ink will increase.

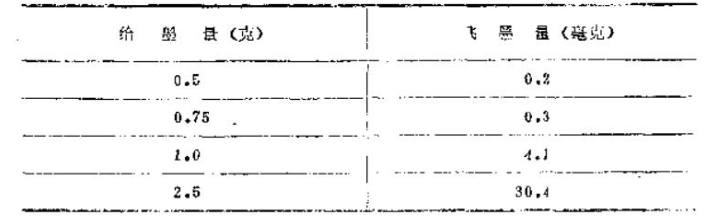

The following table shows that the more ink is supplied, the more serious the misting is. If the ink roller of the printing machine is deformed and worn to cause unevenness, the thickness of the ink layer will be increased to produce more ink filaments, resulting in more ink flying problems.

There is another point that should be noticed, that is, the parts where the large-scale ink is flying are generally the parts with more airflow, that is to say, the airflow brings these oiler droplets to these parts. Of course, changing the air flow does not mean changing the misting, it cannot reduce the phenomenon of misting.

The internal cause of misting is the rheological properties of the ink. Generally speaking, if the elasticity (force) of the ink is greater, the ink will be more viscous. Assuming that other properties are the same, the life of the filaments produced by the ink with greater elasticity ( force) will be shorter. It can also be said that the greater the elasticity of the ink, the shorter the thread head. In this way, the flying phenomenon can be greatly reduced. The yield value of the ink has little to do with Feisheng, because flying ink is mainly related to shear force, and has nothing to do with the structure related to the yield value. Since the elasticity (force ) is greater than the surface tension, ink misting has little to do with the surface tension of the ink.

The electrical conductivity of the ink is a relatively important parameter. If the electrical conductivity (value) of the oiler is larger, the ink will be lighter. Conductive inks such as those on a printer cannot become charged. Water-based ink is electrically conductive, and there is no ink flying when it is printed at high speed.

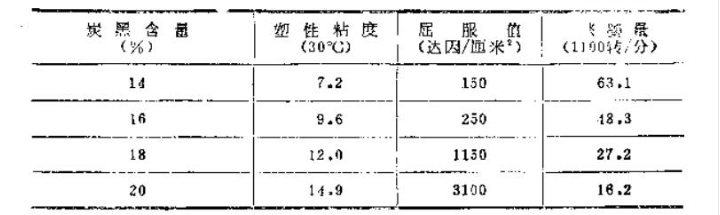

Obviously, for general oil (resin) type inks, their conductivity value is very small. But carbon black has a relatively high conductivity value, generally 10-13 reciprocal ohms. Therefore, the classification of these inks can be found in Between semiconductors and insulators. If the content of carbon black is increased in the ink formulation, the conductivity value will also increase. The relationship between carbon black content and flying ink can be seen in the table below.

The dielectric constant in the ink also has some influence on misting. Due to the repulsive force of the charged filaments, it is very easy to separate the filaments and increase the multi-breakage, thereby increasing the misting. But in an ink with a high dielectric constant, the repulsion is very low. Because the amount of electricity in the dielectric is inversely proportional to the large dielectric constant, the phenomenon of ink flying with high dielectric constant is relatively light.

- 1Working principle of mechanical liquid meter interfacial tensIon Meter

- 2Comparison of Liquid Surface/Interfacial Tension Testing Methods: Plate vs. Ring Method

- 3Selection guide for Surface Tensiometers

- 4Application principle and precautions of platinum ring Surface Tensiometer

- 5Analysis of the difference between contact angle meter and Surface Tensiometer

- 6The working principle, application and operation steps of surface tensIon Meter

- 7Fangrui surface tensIon Meter test data deviation, how to solve?

- 8Comparison of Fangrui's different series of automatic watch interfacial tensIon Meters

- 9What is the measurement principle of surface tension?