The conveying phase of the ink conveying on the printing machine

There are basically two situations in the process of conveying phase: one is that the relatively thin ink (such as news rotary ink, etc.) is pumped (delivered) from the storage tank to the ink fountain on the printing press, and the second is the ink (especially It is a relatively thick ink) from the ink fountain to the printing press. In both cases, the fluidity of the ink is involved . If the fluidity of the oil is not good, (1) the ink is difficult to pump from the storage tank , and (2) the ink is not easy to get off from the ink fountain. ink.

If the thixotropy of the ink is too large, the yield value is too large, the viscosity is too small, the thread head is too short, etc., the combination of these conditions must be that the fluidity is too poor, so that the ink from the ink fountain must be unsatisfactory. of. The good condition of the ink is also related to the leveling of the ink. This is because the rotation speed of the roller that contacts the ink in the ink fountain is very slow , so the ink is basically under a very low shear stress. (Most modern high-speed printing machines are equipped with automatic ink fountain stirring devices, so this phenomenon does not exist). It is close to the flow conditions of oil leveling, that is to say, it basically depends on the flow Spreading performance - relies on the gravity of the ink to flow out horizontally. Therefore, the ink is required to have a relatively small yield value and almost no thixotropy. For example: For , when the critical yield value is 4000 dyne/cm² (data measured by Raleigh viscometer) , there is a direct relationship between fluidity and yield value. However, if the thixotropy is large, the ink will not flow even if the yield value is low. Therefore, the fluidity of this type of ink can be explained by the yield value and thixotropy index. For example, the current yield value is 4000 dynes/cm², and the thixotropy index is 1.6 (based on the static time-shear stress peak diagram method) When measured), the flow is very good, but if the thixotropic index increases, the flow performance will decrease. When the thixotropic index is as large as 3.2, the ink will lose its flow (the yield value has lost its meaning).

Therefore, it is impossible to estimate the fluidity and printing performance of the oil quantity by measuring the plastic viscosity and yield value of the ink. However, from the two parameters of the thixotropic index and the yield value, some ink flow performance problems can be seen. Transgender is more important.

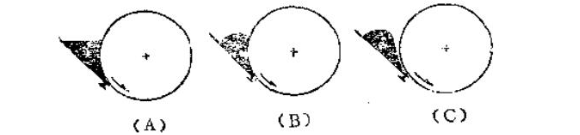

The quality of the ink in the ink fountain can be observed through the phenomenon of ink in the ink fountain. When the ink flow is good, it will also rotate when the fool roller rotates. If the situation is poor will follow the rotation. (off) open, see Figure 19-41.

Figure 1 Ink cleaning in the ink fountain of the printing machine

(A), (B) ink , (C) no ink . Among them: (A) the phenomenon that the yield value of the ink is low and the viscosity is small, (B) the phenomenon that the yield value is high and the viscosity is large (and thus the adhesion is also large); (C) the yield value is high and the viscosity is small (lack of adhesion) sex) phenomenon.

- 1Application of Manual Ink Proofer

- 2How to calculate flexo ink consumption?

- 3Keep your screen printing customers happy with accurate printing colors

- 4Maintain your screen printing quality with proper screen tension

- 5Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 6Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

向华,龚逸仙,李军,林木雄,欧建志 - 《《用于塑料薄膜的荧光凹印油墨的制备与性能研究》》

- 7What faults are prone to photogravure printing? What remedies are there?

- 8Distribution phase of ink transport on the printing press

- 9What effect does ink color have on paper?