Transfer phase of ink transport on the printing press

During the transfer (transfer) of ink from the plate to the paper, a series of meaningful and complex rheological properties are required.

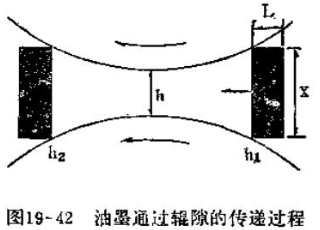

Obviously, the ink transfer (delivery) process is more complicated. Assume that there are two smooth metal rollers coated with ink that rotate against each other (peripheral speed is equal), and the thickness of the ink unit area is x, and the length is L (see Figure 19-42). Before passing through the nip, according to the transfer balance condition, the product per unit area (X*L) is equal, if the ink continues to flow in the direction of the nip due to the rotation of the ink roller, because h<x, so the unit The thickness x of the area is reduced. The surface of the ink layer is in tension.

It can be seen that from h1=x, a pressure that causes deformation per unit area , and the closer to the nip, the greater the pressure. This deformation also causes each oil particle to have a different speed, which creates a problem of speed difference . The speed difference is the largest at h where the gap distance is the smallest. When the ink roller surface starts to separate at h2 , the speed difference decreases. The speed difference between the nips (in frequency unit Hz) is between 10 4 and 10 5 s -1 , and the shear stress is about 107 dyne/cm

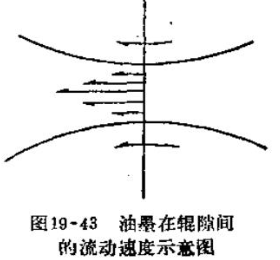

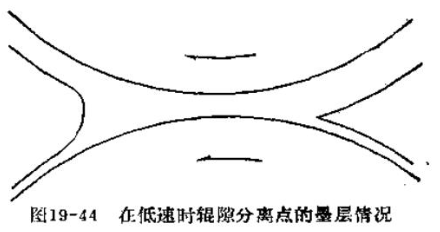

The flow speed is equal to the peripheral speed of the oil roller. In the middle of the nip, that is, at 1/2h, the flow speed of the ink is greater than the peripheral speed of the ink roller. Its velocity distribution is parabolic (see Figure 19-43). At the separation point h2 of the ink roller gap, since the ink is no longer affected by the shear stress, the speed returns to a stable state. At this time, the unit area of the ink also returns to the original state. In the case of stress, the ink forms (Fig. 19-44).

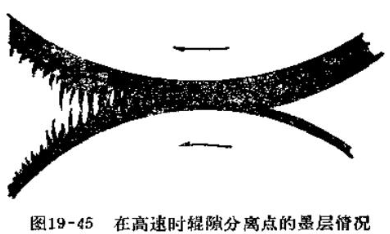

If the peripheral speed is quite large, the so-called "cavitation" phenomenon will occur, causing air bubbles to form in the ink. This bubble begins to expand at the separation point of the nip , and the expansion flows with the radial and tangential direction of the ink around the bubble. Each bubble coalesces with each other, becomes a large bubble, and finally breaks due to mutual impact. This phenomenon occurs when the separated ink layers cannot withstand atmospheric pressure. Therefore, the ink filaments produced by the bursting of the bubbles can be elongated as the roller surface continues to separate until the stress on the ink filaments reaches as much as possible, causing the ink filaments to break at a weak link (see Figure 19-45 ). At this time, the separation process of the base layer and the resulting ink transfer process are completed. The thickness of the ink layer covered on the surface of the two ink rollers is the final ink layer thickness.

The amount of ink transferred by the rotation of the ink roller or the roller can be expressed . It represents the ratio of the thickness of the transferred ink layer to the thickness of the covered ink layer (see Figure 19-46) (in the case of x1>x2)

β=x2 transfer thickness/x1 coverage thickness=x4/x3

It has been proved by experiments that the ink roller made of two smooth and non-absorbent materials can only transfer 50% of the ink supply . Therefore, the ink layer separation coefficient β is approximately 1.

It can be seen that relative motion occurs within the nip range between the elastic and rigid rollers even at equal peripheral speeds . In addition, this relative movement also takes place in the region where the ink filaments separate . The surface of the elastic roller will accelerate the ink filament and cause the ink filament to break at the first weak point close to the elastic roller. Therefore , when the ink is transferred from the elastic roller to the rigid roller surface, the rigid roller can always maintain more than 50% of the ink supply.

The main purpose of the printing process is to reproduce the print as closely as possible to the original. In the printing of halftone prints, since each dot is strictly copied , more satisfactory prints can be obtained. In high-speed letterpress printing , the imprint is imprinted on the paper under a pressure of 60 kg/cm² (milliseconds). Under such a large pressure, a part of the ink will be pressed out of the line, As a result, the amount of stars in the middle of the imprint is relatively small, while more ink is accumulated on the edge, forming twists and turns of dotted lines, making the lines unreal.

When printing on rough paper with lead printing, irregular dot lines often appear. This is because the viscosity of the ink is too small; the ability to resist deformation is relatively poor.

The imprint of ink with high plastic viscosity is not easy to level, especially when the yield value is also high, because it cannot pave the bottom layer. The ink with low yield value and viscosity is easier to pave (flow) the irregular plane of the paper. However, inks with high yield value and high viscosity have better printed dots.

Obviously, the ink transfer process is only completed . This process is of course the process of separating the ink film. Due to the viscosity of the ink, the force acting on the paper when the ink film is separated is very large. If the ink is too viscous, the paper may break or cause plucking. To avoid these disadvantages, the viscosity of the ink should not be too large, and this seems to be contradictory to what was mentioned above, because it has been mentioned that , generally speaking, the viscosity is proportional to the viscosity. Therefore, in the transfer phase from the plate to the paper, the ink should have a relatively high resistance to deformation and the viscosity should be appropriate , so that it can be printed on a web at high speed without pulling out the paper wool.

If the separation ratio of the ink layer increases, the force separating the surface also increases. As the printing speed increases, the viscosity of the ink also increases. Therefore, when the printing speed is relatively low, the viscosity of the ink will also decrease accordingly. It can be seen from this that in order to obtain satisfactory reproductions, the speed of the printing press should be lower-some, and the viscosity of the ink can be correspondingly larger.

Some people think that in offset printing, the transfer rate of ink from the printing plate to the blanket is 50%, and the transfer rate from the blanket to the paper is 76%, so the ink is 38%. In letterpress printing, the transfer rate from the printing plate to the paper is between .

It should also be pointed out that in the process of transferring ink from the plate to the paper, the ink effect on the paper has a lot to do with the quality of the paper.

- 1Ink Rub Resistance Tester: Core Equipment and Application Analysis of Wear Resistance Testing for Printing Products

- 2Ink decolorization testing machine tests ink friction resistance

- 3GB/T36650 Optical Fiber Coloring Ink Performance Testing Scheme [With Instrument Parameters]

- 4What are the functions and benefits of ink friction testing?

- 5Specific steps for ink adhesion selection

- 6Friction resistance of screen printing ink film

- 7What is the light resistance and chemical resistance of screen printing inks?

- 8Stickiness of screen printing ink

- 9What is screen printing ink thixotropy?