The working principle and application of viscosity meter

Viscosity can also be defined as the stickiness of a substance, in other words, it can also be said to be the force required to separate two planes of a certain unit area (they are held together by liquid) at a given speed .

Viscosity includes not only the viscous properties of liquids, but also the elastic rupture properties of solids. It can be seen that viscosity is a very complex comprehensive situation, which is related to factors such as elasticity, adhesion performance and surface tension.

There are many specifications and models of TackOmeter, but so far , the typical one with the basic concept is the so-called ink viscosity meter (ink meter, ink meter) invented by RF Reed -Ink-O- meter. This is an instrument that measures the force of a thin ink film (separation) under power, like a printing press, consisting of two rollers .

Its principle is: when the two rollers rotate, the two layers of ink film coated on the rollers are combined into one layer first, and then they are subjected to shear force between the two rollers, and finally, the ink film is separated (cracked) open. When the ink film is separated, the total instantaneous force is equivalent to the couple force generated by the ink , which is called viscosity by Reid.

The viscosity coefficient is related to the relationship between the ink and the paper, especially when printing on coated paper at high speed, the viscosity of the ink needs to be lower than the critical point, otherwise the phenomenon of paper pulling will occur . If the printing conditions permit, the viscosity of the ink should be as high as possible , so that the printed matter can have clear and complete dots. Viscosity is the resistance inside the molecule, while stickiness is related .

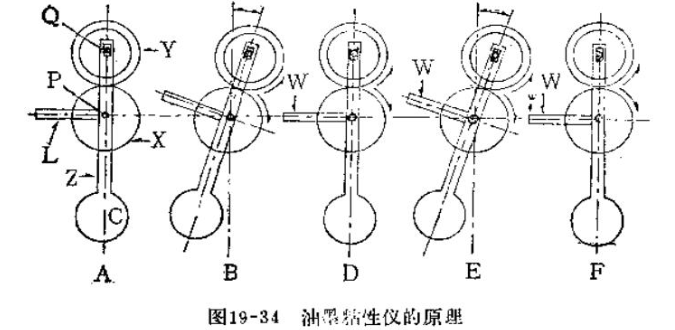

Generally speaking, viscosity is directly proportional to viscosity, that is, the greater the viscosity of the ink, the greater its viscosity. But not all. The basic structural principle of the viscometer can be seen in Figure 19-34.

This instrument uses the contacting X roller and Y roller to measure its force-viscosity when it is constantly rotating under the given pressure, speed and temperature conditions.

The X roller is a metal roller, which is hollow and can be fed with circulating water for mixing. It is driven to rotate , which is connected with the power. The Y roller is a synthetic rubber roller, with Q as the axis, and is pressed on the X roller by its own weight. Both the X roller and the Y roller are mounted on the swing rod Z. Both the swing bar and the roller can swing with P as the axis. There is a lever L on the fork, and a counterweight C on its lower part.

In Figure 19-34: (A) is the state when the instrument is at rest; (B) is the state when the pendulum Z has a certain angle due to the friction between the rollers after the rollers rotate without ink. Deflection: (D) is to add a gravity W to the lever L to bring the instrument back to the state of balance; (E) is to make the pendulum Z have a certain angle after the roller is coated with ink due to the viscosity of the ink The deflection; (F) is to add a gravity w on the lever L, so that the instrument is in a balanced state again.

In fact, the final gravity w added to the lever L is represented by the length of the force arm of the balance weight in meters. The longer the force arm after balancing, the greater the viscosity of the ink, and the shorter the force arm , the smaller the viscosity.

In addition to the above-mentioned main structure, there is also a rubber , so as to ensure that the ink can be evenly distributed on the roller.

Fig. 19-34 is a kind of general ink viscosity meter principle in the world at present (namely couple force measurement method), also has the principle of a kind of viscosity meter to adopt so-called dragging measurement in addition.

Viscometers can perform measurements at similar . At present, the B-45 ink viscosity meter is commonly . There are three speeds: 400 rpm; 800 rpm and 1200 rpm (equivalent to 314, 628 and 942 feet per minute). The C-46 type is rarely used in our country , and its speed is 400, 1200, 2000 rpm.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions