What are the common physical properties of paper?

There are many physical indicators of paper, such as quantitative, size, front and back, longitudinal tip, thickness, tightness, dustiness, whiteness, sizing, smoothness, air permeability, stretch moisture, etc. According to these indicators, the quality of the paper can be evaluated.

Quantitative

The so-called quantitative. Refers to the weight of paper with an area of one square meter, and the unit is g/m². In factory production, 5-10 small pieces of paper , weighed on a balance, and then multiplied by 20-10 times to convert. Quantitative is an index that determines the thickness of paper. Generally speaking, the basis weight of thin paper is low, and the basis weight of thick paper is high. The basis weight of tissue paper is generally between 18-22 g/m² , and that of kraft paper is between 80-110 g/ m² .

size

Size is the length and width of the paper.

front and back of paper

On the fourdrinier paper machine, the pulp flow is laid on a copper wire to be filtered and dehydrated to form paper. Therefore, on one side of the net, due to the loss of fine fibers and fillers with water, the paper surface is relatively rough, leaving net marks 3, while the side away from the net is relatively fine and smooth, which makes the two sides of the paper slightly different. Although it has to be dried and calendered, this difference still cannot be completely eliminated. For the paper made on the rotary paper machine , where the paper surface is in contact with the dryer cylinder, due to the high temperature, the water is paper surface is ironed, so that the paper surface is smooth and the other side is rough. This is called The two sides of paper . The printing and writing effects on the front side of the paper are better than those on the reverse side.

Vertical and horizontal

During the papermaking process, the running direction along the paper machine is the longitudinal direction of the paper, which can be identified from the acute angle presented by the web marks. Perpendicular to the longitudinal direction is the nuclear direction. The physical strength (including tensile strength and folding endurance) of paper in the longitudinal direction is better than that in the transverse direction. Therefore, on the rotary machine, pay attention to loading the paper along the longitudinal direction of the paper when printing.

thickness and tightness

In terms of printing and transportation, the significance of paper thickness is not as great as that of tightness . Tightness refers to the degree of tightness of the paper. If it is the same weight and high thickness, the paper will be loose; otherwise, the paper will be tight. The tightness is directly proportional to the strength of the paper. Generally speaking , the tighter the paper, the better. Tightness refers to the specific gravity, and its unit is the number of grams per cm³ (g/cm³ ) , which can be calculated by dividing the quantitative value of the paper by the thickness of the paper (which can be measured with a paper Thickness Gauge).

Dust

This means that the "small stains" on the paper should be as few as possible.

BaiDu

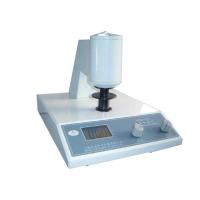

Whiteness refers to the brightness (brightness) (not light), the more light the paper reflects, the whiter it is. Whiteness is generally measured by instruments, and it is customary to use the unit "%" of whiteness as a synonym for "degree". For example, the whiteness of newsprint is 75-80% (degrees).

Sizing degree

Indicates the size of the paper's water resistance. A duckbill pen is often dipped in a special standard ink to draw a line on the paper within 2-3 seconds to see how wide . The unit is millimeters.

smoothness

Generally speaking, the smoothness of the paper is expected to be higher. The smoothness of paper is to allow a certain amount of air to pass through a certain area of ommatidium under specific conditions, to flow between the smooth glass plate and the surface of the paper, and to measure the time it takes for the air to pass through. Fast passing speed means low smoothness and rough paper surface; slow speed means high smoothness and fine paper surface, the unit is in seconds.

All printing papers require a certain degree of smoothness. Printing pictures usually use an 85-line mesh plate per inch (25.4mm), and there are more than . The color picture of the 133-150 line mesh version has 23-36 fine points. If you want to print fine dots clearly, the paper is required to be very smooth. If the paper is not smooth, the amount of ink will be increased, and a relatively large impression force is required during printing so that the depressions of the paper can also be filled with ink. As a result, the cost increases and the printing quality decreases.

air permeability

Air permeability is an index to check the moisture-proof performance of paper. The tighter , the less air permeability it has. The unit of air permeability is milliliter (ml), which refers to the amount of air that passes through 10 cm* of paper in one minute .

Scalability

The stretch rate refers to the relative change in paper size after immersion and drying. In color overprint printing, the smaller the expansion ratio of the paper, the better. The stretch rate is expressed for elongation and a negative sign (-) for contraction.

moisture

Paper is placed in the air, and its water content often changes with the relative humidity . On the one hand, this is due to the presence of bound water inside the fiber, and on the other hand, it is the result of maintaining a balance with the relative humidity in the air. Rolled off the paper machine

The water content of paper is about 5-12%. The moisture content of paper has a great influence on storage and use. If the moisture content of the paper is too high, it will reduce . If the moisture is too small, the paper will be brittle.

- 1Porosity Tester verification & maintenance

- 2Determination Principle and Maintenance of Paper Smoothness Instrument

- 3Application of Porosity Tester in Thermal Paper

- 4Briefly describe how different industries view product packaging

- 5Simple and Accurate Method for Measuring Gram Weight (GSM) of Paper/Board/Corrugated Board and Laminates

- 6What are whiteness and yellowness?

- 7What is the whiteness index?

- 8How can the paper industry achieve greater whiteness?

- 9How to use the differential pressure method to test air permeability?