Paper chemical pulp production process: introduction to cooking

A very important process in the production of chemical pulp is cooking. Its purpose is to allow chemicals to react with lignin in the raw material as much as possible, so that it can be separated from the intercellular layer (the "common area" between adjacent cells is called intercellular layer). interlayer), and less loss of the degree of polymerization of cellulose, maintain a relatively high strength, but also retain some hemicellulose. Because hemicellulose is beneficial to the "swelling" effect of fibers in the "beating" operation, so that better wood pulp can be produced.

The cooking process is achieved by processing raw materials under high temperature and pressure.

After cooking, go through: (1) washing. To remove non-fibrous impurities and residual chemicals . Another purpose of pulp washing is to reduce the consumption of bleaching agent during bleaching; (2) Screening. Its purpose is to remove the undigested part, debris, lumps, etc. in the pulp; (8) bleaching. Generally, cheap calcium hypochlorite is used to bleach the pulp; (4) beating. Practice has proved that the pulp used for papermaking needs to be treated mechanically (or by physical and chemical methods) in water. Otherwise, the paper produced is a thin sheet with loose tissue and low strength, which has no practical value . This is because after the paper is cooked and bleached, there are still some fiber bundles mixed in it . Some individual fibers are either too long or too thick, or the surface is smooth and hard itself. thin paper.

The operation process of pulp "mechanically treated in water" is called "beating". After beating, the paper is compact, uniform and has good strength.

During the beating process, due to the influence of water and mechanical force, the fibers are subjected to impact, swelling , cutting, crushing and dispersion. As a result, the fiber bundles are separated, the long fibers are cut to a suitable length, and the fibers that have been disintegrated and split become soft due to simultaneous water absorption and swelling. Therefore, the beating process is essentially a very complex physical and chemical change process of fibers. The fibers absorb water molecules in water, and are subject to mechanical impact and mutual friction between fibers, making the primary wall and secondary wall (cell wall) outside "Cracks" appear in the first layer , and even partially worn or peeled off, so that it is ready ; (5) Papermaking. The so-called papermaking is actually a dehydration process of fibers, that is, to let the pulp disperse freely in water first, and then escape the dehydration to make the fibers interweave with each other and become paper.

The higher the pulp consistency, the more opportunities for fiber flocculation and entanglement, and the more uneven the formed paper sheet . Generally, when making paper, the concentration of the pulp should be controlled between 0.3-0.7%, and when making thin paper, the concentration of pulp should be lower. The minimum concentration can reach 0.1%. Of course, low concentration does not necessarily ensure uniform , because the slurry will produce "flow direction" during the flow process. Therefore, the design of the headbox also needs to take into account the uniform dispersion of the fibers and the smooth flow of the slurry onto the copper mesh.

Copper mesh is a net made of copper wire with many meshes on it. Copper mesh with different "mesh" can be used for copying different kinds of paper. The so-called mesh refers to the number of meshes per inch (25.4 mm). A large mesh means a small number of "mesh" and fast water filtration; a small mesh means a large number of "mesh" and slow water filtration. The copper mesh used for papermaking generally has specifications such as 60 and 100. The pulp is dehydrated on the copper net to form a wet paper sheet in the following ways: ①Free dehydration, using the gravity of the water itself and the suction force when the table roller rotates, so that the water leaks through the copper net; ②Vacuum dehydration, using a Vacuum Pump to draw Suction, make the suction box generate negative pressure and force the water in the fiber gap to be discharged; ③Mechanical dehydration, use the extrusion force of the upper couch roller to remove the water . When the wet paper leaves the copper section, it generally contains about 85% moisture. At this time, the tissue is relatively loose.

Next, the wet paper is sent to the press section, and the paper is forced to be squeezed by two press rollers separated by felts and rotated , so that the moisture content in the paper reaches about 65%. Although mechanical pressing can squeeze out part of the water, it is impossible to remove all the moisture in the paper , because the first pressure cannot be too large, otherwise the wet paper will be crushed; The bound water of the "water bridge" cannot be removed by mechanical pressure .

In order to further dehydrate, it is necessary to use a drying section composed of multiple cylindrical drying cylinders to remove moisture by heating and evaporating, so that the paper reaches a dryness that is generally suitable for applications (88-95%). The temperature of the first few drying cylinders in the drying section is generally around . The wet paper is preheated, and the temperature of the drying cylinders in the middle part is generally around 100-105°C, which is the key to paper dehydration. Then, the temperature is lowered to about 80°C to gradually cool the paper sheet.

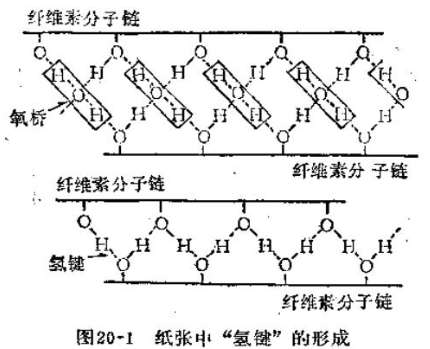

When the paper is heated and the water molecules escape, the "water bridges" that are combined with the cellulose molecules, that is, the oxygen bridges, are destroyed. Due to the effect of surface tension when water evaporates, the fibers closer to each other. The hydroxyl groups in the cellulose molecule are shortened to a very small distance (2.55-2.75) from each other , and the hydrogen atom in one hydroxyl group is tightly combined with the oxygen atom in the other hydroxyl group to form a "hydrogen bond", as shown in Figure 20 -1.