Also apply the film manually? Automatic small coater saves 50% energy and has an accuracy of up to 0.1um!

Manual coating, different force and speed control, sometimes it is difficult to ensure the consistency and precision of the coating. The automatic film coating machine can well solve the problem of constant speed and constant pressure.

The use of experimental automatic film coating machines in colleges and universities is relatively common. After all, scientific research experiments have very high requirements for the control of coating film precision.

Cooperation cases of some colleges and universities in NBCHAO Mall

In the field of new materials, thin film experimental research is an important part of quality inspection, but the difficulty of thin film substrates to ensure smoothness is also one of the intractable diseases of coating films. In addition, the temperature requirements for the film coating of rubber products also increase the difficulty of manual film coating.

The automatic film coating machine has attracted more and more users' attention for its constant temperature, constant pressure, constant speed and vacuum adsorption function for film substrates.

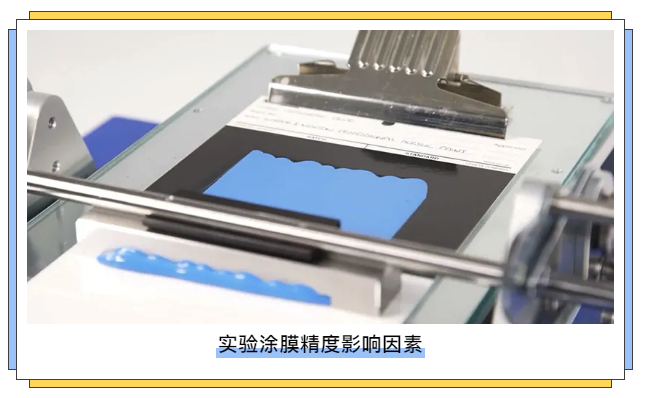

Factors Influencing the Accuracy of Experimental Coating Film

1. The material itself

A. The volatile fluid is difficult to control;

B. High viscosity is easy to scratch;

C. Samples with high environmental requirements: such as glue and lithium batteries require heating;

D. The grinding fineness should not be larger than the groove of the film coating device.

Second, the material of the coating film substrate

A. The water absorption of different papers has different ink absorption;

B. The film substrate is difficult to level;

C. Flatness and roughness of tin plate.

3. Accuracy of coating equipment

As a coating platform, the coating machine itself does not control the film thickness, and the control of the film thickness is determined by the wire rod or the Applicator matched with the coating machine. Therefore, the accuracy of the wire bar and the Applicator decisively affects the accuracy of the coating film.

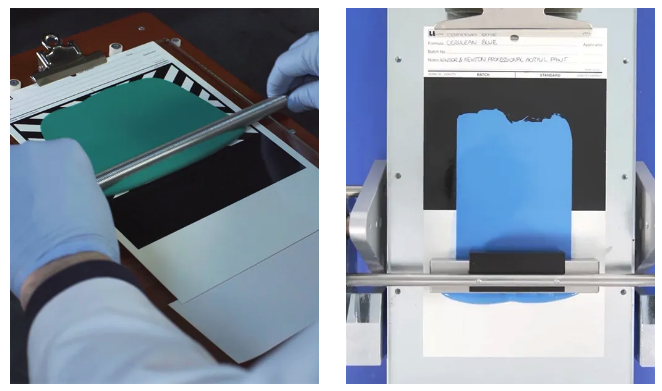

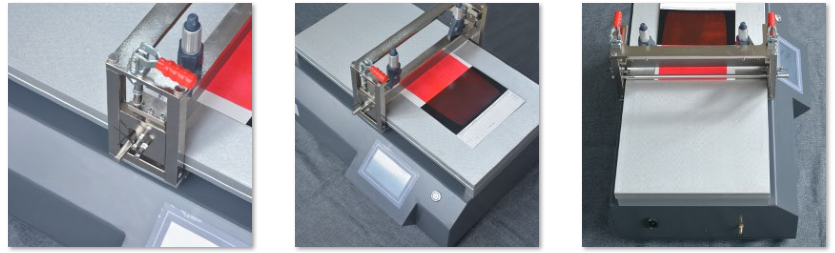

Wire Bar Coater: various film thickness, unlimited environment, ultra-thin coating (as thin as 1.5μm)

Scraper type Applicator: no scratches, easy to clean, suitable for ultra-thick coatings (thickness up to 5mm)

4. Human error

In addition to the influence of the above factors, the speed of the coating film and the control of the pressure at both ends also have a great influence on the control of the film thickness, especially on soft substrates, the uneven extrusion phenomenon that may be caused by excessive pressure, resulting in The phenomenon of scratches on the coating film one by one. Different viscosity samples require different speed control.

So why should you consider a film coating machine, do you understand? (✪ω✪)

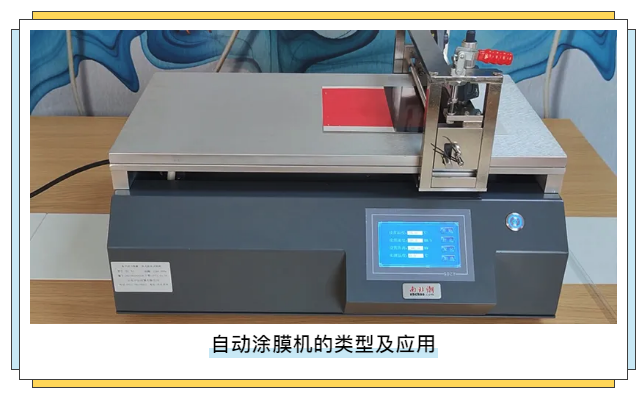

Types and applications of automatic film coating machines

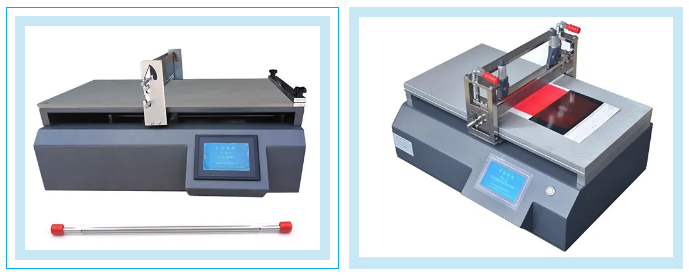

1. The difference of coating equipment

● Wire Bar Coater (below left); ● Doctor Blade Preparer (below right)

2. Different configuration functions

●Ordinary type; ●Heating type; ●Vacuum adsorption type

★All configurations can be freely combined and selected, such as simple wire rod type, wire rod scraper integrated, wire rod scraper+heating+vacuum, etc., and the north and south tides support customization .

configuration function | Main Application Selection |

wire rod | Ultra-thin/high-precision coating film, multiple coating |

scraper type | High-viscosity samples, relatively large film thickness, and large particle size |

heating type | Lithium battery film/glue, etc. need to be coated at a certain temperature |

vacuum adsorption | Difficult-to-level substrates such as thin films |

Remark | The fabric substrate is breathable, so vacuum is not an option. Choose vacuum for uneven paper. |

NBCHAO provides different coating solutions for thousands of customers with different applications every year, supports free sample testing services, and a convenient after-sales system to quickly solve user problems.

Scan the WeChat below, consult technical engineers online, and get help for film coating machine selection and more technical information!

WeChat ID|tuliaoz

Consulting Hotline|4006007498

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research