LAB Film Applicator selection, do not step on these pits!

How to choose the type of laboratory Film Applicator? Which pits should be avoided? In fact, the experimental Automatic Film Applicator is a Film Applicator platform that replaces artificial film. The accuracy of the film is mainly determined by the film apparatus, but the structural design of the Film Applicator also affects the film effect to a certain extent.

The selection of the experimental small Film Applicator is not difficult. It is still the same as the artificial Film Applicator. It depends on the properties of the sample, the film substrate, and the film thickness requirements to determine whether it is necessary to configure the heating or vacuum function, the scraping Film Applicator , the film appliance, etc. However, it is simple and simple. During the selection process, some pits are still easy to step on. Once you step on them, the selected equipment will be uncomfortable to use. The key is not consumables. Share a few points today, so that you can avoid detours and successfully cross the pit.

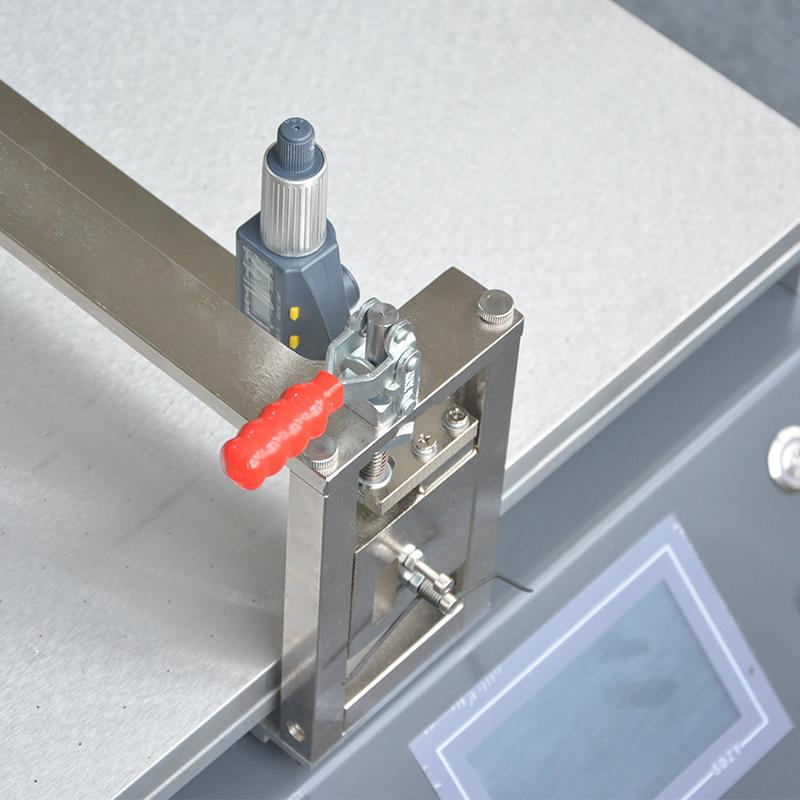

Film Applicator pressure bar load is not enough

An important part of the structural design of the wire rod Automatic Film Applicator is the load. There is a pressure rod with a load on the wire rod, which applies pressure to the wire rod for scraping. If you want to scrape an ultra-thin film on an ultra-thin substrate, the film thickness is even less than 2 microns, then when you choose the Automatic Film Applicator, pay special attention to whether the pressure is sufficient. If it is not enough, the scraping film may be too thick due to the gap between the rod and the substrate.

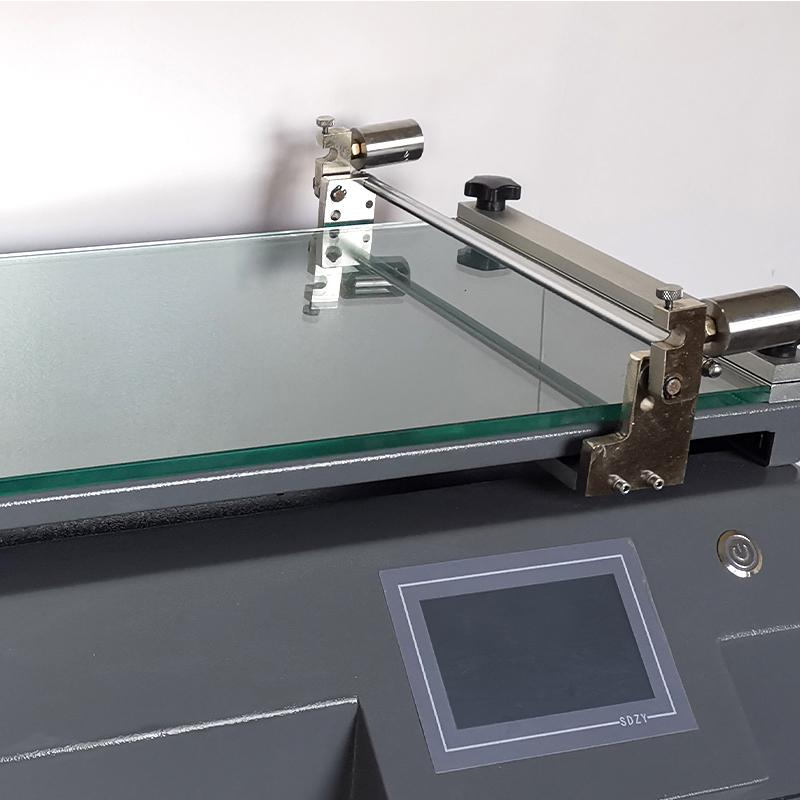

Drawdown Vacuum Plate Holes Too Large

There are vacuum holes on the Drawdown Vacuum Plate of the vacuum type Automatic Film Applicator, and the size of the vacuum holes determines the adsorption effect of the Film Applicator substrate. The finer the vacuum holes, the better the smoothness of the adsorption, especially for very thin film substrates. Of course, the smaller the aperture, the more difficult it is to produce, the greater the cost, and the larger the aperture, the simpler it is. Under normal circumstances, the aperture is about 0.8mm. If it exceeds 1mm, because the film is too thin, it is easy to cause the scratched film to have a trace.

Vacuumpump built-in or external row

We all know that the pump will have a certain vibration when it is working. If it is an Automatic Film Applicator with a built-in Vacuumpump, then in the film process, the equipment will generate vibration to some extent, which will affect the experimental film. If very small vibration is to be achieved, then the technical requirements are very high, which greatly increases the production cost. Therefore, many domestic manufacturers have chosen the external Vacuumpump to experiment with the vacuum adsorption function and reduce the vibration of the machine to avoid the film being affected by vibration.

The precision of film equipment is not good

After all, the laboratory Spreader is only a Film Applicator platform, and the film accuracy is still affected by the Spreader appliance. If the film appliance is selected well, then the film thickness accuracy control is better. If the precision of the film device is average, then the precision of scraping and coating is relatively average. Moreover, when choosing film appliances for different samples, it depends on whether the wire rod type or the scraper type is selected, and the wrong appliance cannot be selected in order to save costs. Generally, the wire rod for low viscosity film samples, the film is lower than 40μm, and the precision of the imported wire rod will be higher; in addition, for high viscosity and high film thickness samples, use a scraper.

The flatness of the baseplate is not good

In the film experiment, one thing is to require the flatness of the Film Applicator platform. If the workmanship is poor and the Spreader platform is uneven or rough, it will inevitably affect the effect of the scraped film. However, this problem does not exist in the Spreader equipment on NBCHAO, which has undergone quality review.

The above are the FAQs in the selection process of the laboratory Film Applicator , hoping to help users who choose the Automatic Film Applicator. If you have more detailed questions, you can communicate with the NBCHAOtechnical engineer.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Laboratory Film Applicator for Spreader Chitosan Film

- 5Application of doctor blade coater in electrode and solid electrolysis preparation

- 6Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 7Experimental application of water-based paints on film laminating paper by laboratory coater

- 8Experimental coater application case video of liquid silica gel on release paper

- 9Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]