Gurley triad test paper test paper smoothness

(1) Gurley Tripod

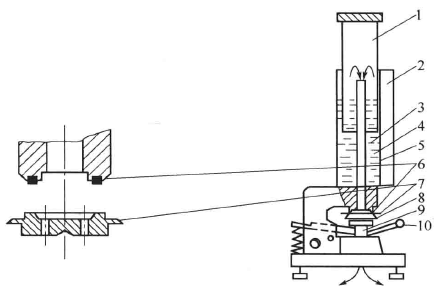

①Structure and working principle Gurley three-purpose instrument is composed of outer cylinder, inner cylinder, pressurizing device, chuck, etc., as shown in Figure 2-8, and is suitable for measuring the smoothness, air permeability and softness of paper. The principle of the Gurley three-purpose instrument to measure the smoothness of paper is: put the sample on the sample holder, lift the inner cylinder, and the inner cylinder falls by its own weight, so that a certain amount of air passes through a certain area under a certain pressure The time required for the measurement is the smoothness value of the paper.

② Calibration procedure

a. Check the tightness. Place a metal sheet or cellophane in the paper sample holder to clamp, then lift the inner cylinder and keep it for 5 hours, the air leakage shall not exceed 50mL.

b. Calibration of the weight of the inner cylinder should be within the range of (567±1)g.

c. Proofreading of the simple volume of the inner circle.

Figure 2-8 Gurley three-purpose instrument

1-measuring cylinder; 2-panel; 3-breather pipe; 4-oil; 5-fixed cylinder; 6-upper measuring ; 7-sample; 8-lower measuring plate; 9-bracket; 10-test Sample clamp handle

(2) Test method

①Sample collection and processing. Sampling shall be carried out according to GB450, and temperature and humidity pretreatment shall be carried out on the samples according to the requirements of GB 10739.

②Adjust the level of the instrument, remove the inner cylinder, inject special oil into the outer cylinder, and the oil level reaches the ring-shaped line on the middle surface of the outer cylinder.

③ Raise the inner cylinder until the spring pointer is connected to it under its flange. After clamping the specimen, do not raise the inner cylinder; otherwise, oil will be sucked into the air tube.

④ Install the measuring head and related gaskets on the instrument.

⑤Insert the processed and balanced sample into the puncher on the base, and punch a small round hole. The number of layers of paper depends on the smoothness of the sample. For general printing paper, eight layers of paper can provide a more suitable reading.

⑥ Clamp the punched sample in the sample holder to ensure that the punched hole is not covered by any part of the ring contact of the clip.

⑦ Slowly clamp the sample with a rod-shaped screw, reverse and leave, and use the weight of the lever arm to apply clamping pressure.

⑧Let the inner cylinder fall freely, and when the zero mark line is aligned with the top of the outer cylinder, start the stopwatch or timer immediately. The inner cylinder presses out the air in the system by its own gravity, and it also falls for a certain distance. When the 50mL engraved line is aligned with the outer cylinder, stop timing, and the counted time is the smoothness, and the unit is s/50mL.

-

CHINA BLD-PH10 Smoothness Meter$ 1695.00

-

-

-

-

-