How to test the surface roughness of paper by needle tracing method?

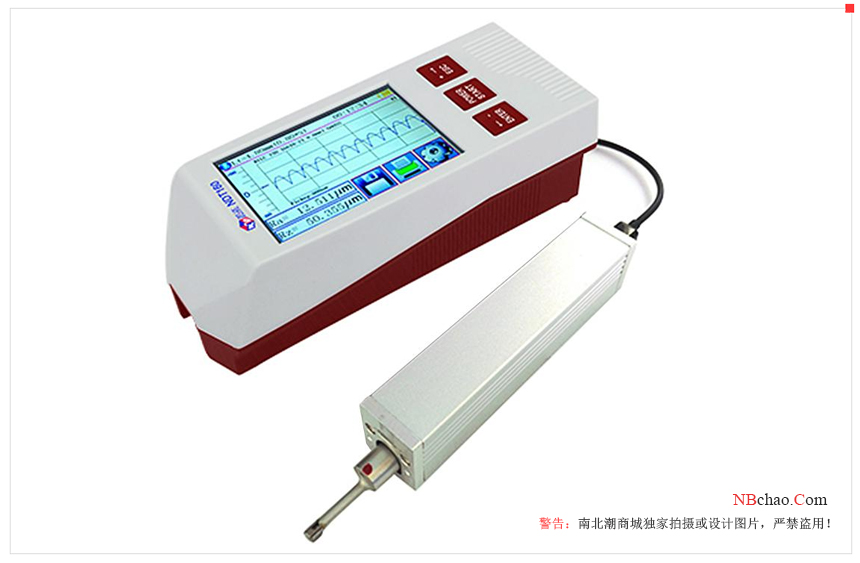

The needle drawing method is one of the methods for measuring the microscopic geometry of the surface. It uses a very sharp stylus to slide at a constant speed on the surface of a paper sample glued to a smooth glass plate. Due to the uneven peaks and valleys on the surface of the sample, the stylus moves up and down. If the up and down displacement parameters of the stylus are amplified and processed by mechanical or electrical methods, the recording instrument can be used to display the graph of its microscopic geometric shape. The test instrument is a needle roughness meter, which is suitable for measuring the degree of concave-convex shape of the printing surface and the microscopic condition of the surface. It consists of an amplification indicator, a signal transmission, a Detector, a recording system, a fixed plate with columns, and an inclination adjustment table. The testing principle of the SE-3A needle roughness meter is that the stylus touches the surface of the printing paper sample and sweeps a certain distance. Corresponding curves are given according to the unevenness of the printing surface, and are enlarged and displayed by the magnifying device. The shape of the curve reflects the degree of unevenness of the paper surface. The gentler the curve, the higher the smoothness; otherwise, the higher the roughness.

-

-

CHINA BLD-PH10 Smoothness Meter$ 1695.00

-

-

- 1Influence of smoothness on paper printing and its solution

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3Evaluation of steel surface roughness

- 4The relationship between abrasive and surface roughness

- 5Roughness and Surface Roughness

- 6Which industries need to use surface roughness meters?

- 7Surface roughness measurement

- 8What are the application fields of surface roughness meter?

- 9What are the main manifestations of the influence of surface roughness on parts?

-

KAIRDA NDT151P Roughness Gauge$ 810.00

-

-

-

-

-