Test method of dynamic friction coefficient and static friction coefficient

When two objects in contact with each other slide or have a tendency to slide relative to each other along the contact surface, a force that hinders this movement acts on each other, that is, friction. The friction force when there is no relative sliding is called static friction force. The frictional force when sliding occurs is called sliding friction. During the printing and packaging process of paper, when paper is in contact with paper or other materials, friction forces are usually generated, and these friction forces have a great impact on printing and packaging production. For example, if the paper used for paper bags has too high a coefficient of friction, there may be adhesion between stacked paper bags, while too low a coefficient of friction may cause slippage between stacked paper bags, which will affect the packaging quality.

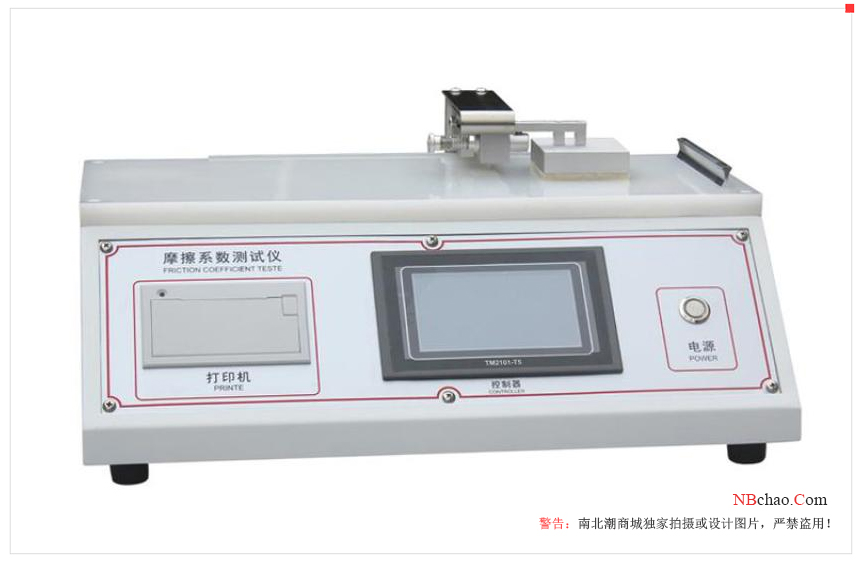

According to the friction theory, under certain positive pressure conditions, the friction force is proportional to the friction coefficient. The coefficient of friction of paper can be measured by using the static and dynamic friction coefficient instrument developed by the Netherlands Packaging Research Institute. In addition, the MXD-02 friction coefficient meter produced by Jinan Languang Electromechanical Technology Co., Ltd. can also test the dynamic and static friction coefficients of packaging materials.

(1) Static friction coefficient test

The static friction coefficient meter is composed of a motor-driven tilting table, a sample chuck and a weight block. The principle of the test is: put the weight block on the left side of the table and at a horizontal position, then start the motor to make the table tilt slowly. When the weight block starts to slide, stop the motor immediately, and read the coefficient of static friction directly on the dial. The specific test steps include the following points.

①Sample collection and processing. Sampling according to GB450, cut samples of two specifications of 80mm×180mm and 30mm×120mm, two pieces are matched as a group, and the temperature and humidity of the samples are pretreated according to the requirements of GB10739.

②Put the instrument on a platform and adjust it to the level, and turn on the power. Use the motor switch to adjust the tilting plate just in the horizontal position, at this time the pointer of the instrument just points to the "O" point of the dial.

③ Loosen the locking boom on the table, align it with the table, and clamp the 80mm×180mm sample on the inclined plate.

④ Clamp the 30mm×120mm sample on the weighted slider with spring rubber spokes, and place the slider together with the sample on the left side of the inclined plate.

⑤Push the motor switch to the right, the motor runs to make the inclined plate rotate clockwise, and tilt more and more, carefully observe the slider, once the slider starts to slide, release the switch immediately, the motor stops moving.

⑥ Read the coefficient of static friction from the position pointed by the pointer on the dial, that is, tana, where α is the inclination angle of the inclined plate when the weight block starts to slide.

⑦Push the switch to the left, the tilt plate moves counterclockwise to return to the horizontal position, release the switch, the pointer points to zero, ready for the next test.

The test results are expressed as the arithmetic mean value of the kinetic friction coefficients of all samples, and three significant figures are taken.

(2) Dynamic friction coefficient test

The dynamic friction coefficient meter is composed of a pendulum with a certain weight, a cylindrical drum and a pointer dial. The pendulum is fixed to a rotatable cylinder that can be released from a horizontal position. The sample strip is wound around the cylinder, covering 1/4 of the circumference of the cylinder. Hang a clamp with a certain weight on the other end of the sample, so that a certain pressure is generated between the sample and the cylinder. When the pendulum is in the initial position, it has potential energy E; when the pendulum falls, the friction between the sample and the cylinder prevents the pendulum from rising, and the potential energy of the pendulum at this time is E2. The coefficient of dynamic friction is calculated by friction energy consumption (E1-E2), and the value can be read directly from the dial during the test. The specific test steps include the following points.

①Sample collection and processing. Sampling according to GB 450, cut 5 samples of 15mm × 200mm, and carry out temperature and humidity pretreatment on the samples according to the requirements of GB10739.

②Clamp one end of the sample in the horizontal fixture, wrap the other end in 1/4 of the cylinder, and clamp a 100g weight block on the end point.

③Lock it after placing it horizontally, and turn the pointer to the maximum position. Push the pendulum locking lever to let the pendulum fall freely, gently catch the pendulum with your hand when it returns, place it in the locked position, then read the dynamic friction coefficient at the position pointed by the pointer on the dial, and take the average value of the test results.

④ If you need to measure the coefficient of friction between paper and other materials, you can replace the cylinder of different materials for the test.

The test results are expressed as the arithmetic mean value of the kinetic friction coefficients of all samples, and three significant figures are taken.

- 1Difference between static friction coefficient and dynamic friction coefficient

- 2What is the coefficient of friction and how is it determined?

- 3Why is coefficient of friction testing important?

- 4What are the packaging quality test methods?

- 5How does it work to calculate the coefficient of friction of plastic packaging films?