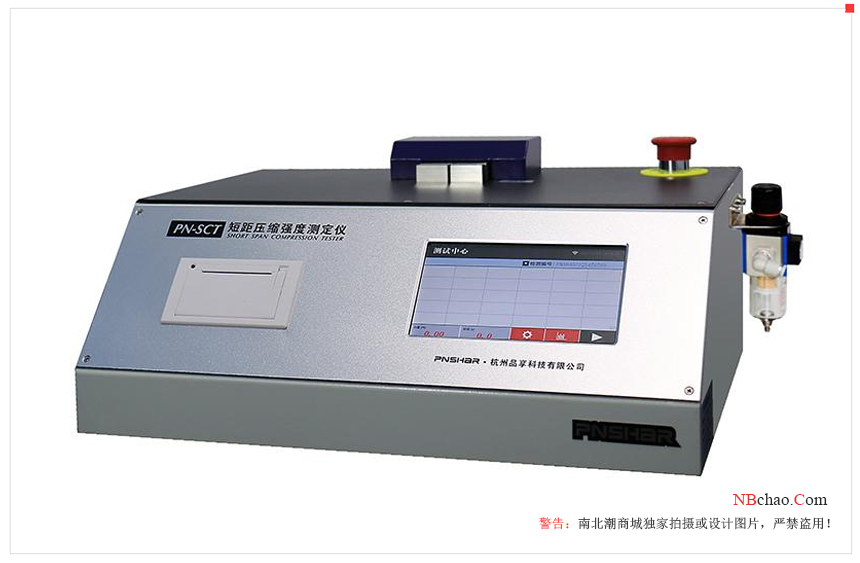

Principle and Operation of Short Range Compression Tester

Structure and working principle

The short-distance compression Tester is composed of a clamping device, a control device, a display, etc. Put the sample between the clamps, press the test button, and the clamp will automatically clamp the sample under the action of air pressure, and then the sample will be clamped perpendicular to the clamping force. Apply pressure in the direction to crush the sample, and the maximum pressure value will be displayed on the instrument display. Because the compressed distance of the sample is only 0.7mm, it is called a short distance compression Tester.

Calibration procedure

a. Turn on the power and preheat the instrument for 30 minutes.

b. Adjust the zero point of the instrument and check whether its calibration value is the same as the standard value. If not, use the potentiometer to adjust to ensure the linearity of the pressure sensor.

c. The clamping force of the instrument can be checked with the pressure gauge on the side of the instrument.

d. The accuracy of the display value of the instrument can be measured by weight suspension method, the correction value is equal to 0.015 times of the display value of the instrument, and five points should be selected for calibration within the full range of the instrument.

e. Measure whether the distance between the left and right clamps is 0.7mm with a high-precision plug ruler. Before use, the plug ruler should be calibrated with a high-precision Thickness Gauge.