What is the principle of corrugated core flute meter?

Structure and working principle

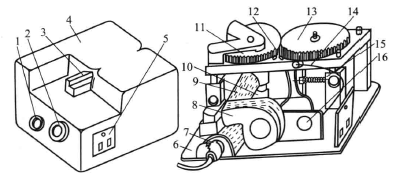

Corrugated core flute Tester is a special instrument for making corrugated core samples. Figure 2-35 is a WAG corrugated core flute Tester. Under the condition of 177°C, a pair of rollers with the same tooth shape parameters are used to pressurize the sample to form the corrugated core. The instrument is equipped with a motor and a movable system, a pair of A-shaped corrugated rolling wheels, a Heating Plate that can reach the temperature condition is installed under the rollers, and a comb plate and comb teeth for making corrugated core samples.

Figure 2-35 Corrugated core flute Tester

1-power socket; 2-wind hole; 3-sample introducer; 4-only cover; 5-switch; 6-bottom plate; 7-wire; 8-cooling fan; 9-air duct;

11-active rolling wheel; 12-sample guide groove; 13-passive wheel; 14-Heating Plate; 15-passive roller pressure regulating spring; 16-temperature regulator

Calibration procedure

a. The meshing of the two wheels should be proper. When the instrument reaches 177°C, feed 12.7mm wide paper and carbon paper between the two wheels for testing. The indentation lines of the carbon paper on the paper should be evenly distributed.

b. If the indentation lines are unevenly distributed, check the roller bearing clearance and the contact between the Heating Plate and the roller, etc.

c. Check the temperature of the wheel, cover the instrument cover, when the temperature reaches, the control light goes out; remove the instrument cover, measure the temperature of the wheel with a suitable thermometer. If it meets the requirements, the normal test should be carried out after covering the instrument cover; otherwise, it can be adjusted with a temperature regulator.