How to test Ring Compressive Strength (RCT)?

Test Principle

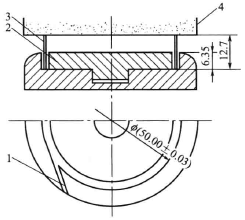

The ring compressive strength of cardboard refers to the maximum pressure that a sample of a certain size can withstand before being crushed when a sample of a certain size is inserted into the sample holder to form a ring and compressed between two measuring plates. The unit is expressed in N. The test instrument uses a spring plate type compression Tester and a sample holder, and a sensor type compression Tester can also be used. The sample holder is a device for clamping and fixing the sample, as shown in Figure 2-36, it consists of an outer disk and an inner disk. The sample is inserted between the outer disk and the inner disk of the sample holder to form a circular sample.

Figure 2-36 Sample holder

1-sample socket; 2-sample core plate; 3-sample; 4-upper platen

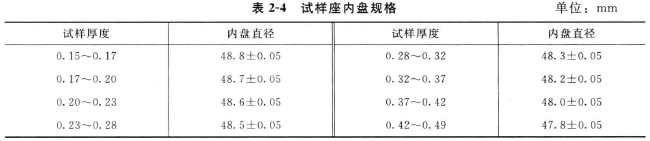

The diameter of the inner disk has different specifications according to the thickness of the sample, as shown in Table 2-4.

Test Methods

The test is carried out according to the national standard GB 2679.8 "Determination of Cardboard Ring Compression Strength". The specific test steps include the following points.

a. Sample collection and processing. Sampling according to GB 450, cut 10 samples each with a width of 12.7 mm and a length of 152 mm with a special punching knife along the longitudinal and transverse directions of the paper web, and the non-parallelism of the two sides of the sample is less than 0.015mm. According to the requirements of GB10739, carry out temperature and humidity pretreatment on the samples.

b. Insert the sample into the sample holder vertically and horizontally respectively, and then place the sample holder at the center of the lower platen, with the sample opening facing forward. When inserting the sample, half of the front faces inward and the other half faces inward. , Note that the orientation of the interfaces at both ends of the sample should be uniformly facing the operator. Adjust the pointer to zero.

c. Start the compression Tester to make the upper platen lower and compress the sample evenly until the edge of the sample is crushed, lift the upper platen after the pointer no longer moves, record the maximum bending deformation of the spring plate (that is, the reading of the dial indicator), and then Find the maximum pressure required to crush the sample from the stress-strain curve of the spring plate, accurate to 1N.

For the sensor-type compression Tester, after the sample is crushed, stop the instrument, then reverse the motor to return the upper platen to its original position, and record the reading on the display, that is, the ring compression strength.

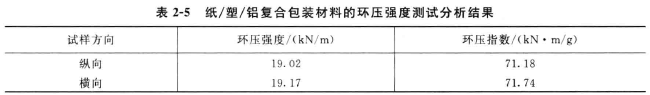

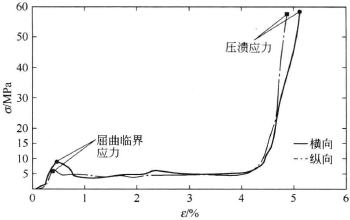

For example, Table 2-5 and Figure 2-37 are the analysis results of the ring crush strength and ring crush index of Tetra Pak packaging paper/plastic/aluminum composite materials, and the influence of the longitudinal and transverse directions of the cardboard on the puncture strength of this composite material Very small, the transverse ring compressive strength is slightly higher than the longitudinal.

Figure 2-37 Ring compressive stress-strain curve of paper/plastic/aluminum composite packaging material

- 1YT-H152 Ring Pressure Sampler Operation Manual

- 2YT-YSK series compression testing machine operation instructions