Pressure sensitive adhesive tape

The preparation of pressure-sensitive tapes generally includes:

(1) Manufacture of pressure-sensitive adhesive; (2) Coating of pressure-sensitive adhesive and dry coal; (3) The process of coiling, cutting and packaging of pressure-sensitive tape. The manufacturing methods and equipment of various types of pressure-sensitive adhesives have been described in more detail in the previous chapters, and will not be repeated here.

The coating and drying process of pressure-sensitive adhesives is done on specially designed coating and drying machines, which are the central part of the manufacturing of pressure-sensitive adhesive tapes.

Coating process and coating performance of pressure-sensitive adhesives

The so-called pressure-sensitive adhesive coating process refers to the process of evenly coating pressure-sensitive adhesive (including primer and height separator, etc.) on the substrate with a specially designed coater.

In order to produce high-quality pressure-sensitive tapes, in addition to choosing the right materials such as pressure-sensitive adhesives, substrates, primers, and release agents, the more important thing is the designcompareThe right coating process and the right equipment. The principle of design is not only to ensure that the quality of the adhesive line, such as the thickness of the adhesive line and the appearance of the tape, is not only to ensure that the quality of the adhesive line is determined, but also that the coating operation is high and very reliable. Over herecompareIt is important to choose a pressure-sensitive adhesive based on its coating properties and the specific requirements for the tapecompareAppropriate coating method and applicator, and determine the various process parameters of the coating operation.

The viscosity and other rheological properties of pressure-sensitive adhesives affect their coating behaviorcompareImportant performance. We know that according to the dependence of viscosity with shear velocity, fluids can be distinguished into three types: Newtonian fluids, expanses, and pseudoplastics. According to the change of viscosity with shear time, the fluid has Newtonian fluid, f; There is a distinction between ivariants and rheological variants. The greater the rheological properties of the pressure-sensitive adhesive from the Newtonian fluid, the more prone it is to quality problems during the coating operation. Especially when the pressure-sensitive adhesive presents the properties of an expansive body, because its viscosity will increase rapidly with the increase of coating speed (i.e., shear speed) during the coating process, it takes a large mechanical force to make the adhesive unfold, so the faster the coating speed, the more difficult it is to get a uniform coating, and often the substrate will be broken due to excessive tension, and even damage the scraper. When the adhesive exhibits thixotropic properties, the leveling of the adhesive layer is poor when applied, so it is difficult to obtain a smooth pressure-sensitive adhesive line.

(1) Coating performance and process of solution-type pressure-sensitive adhesive

When the viscosity is small, the rheological properties of solution-type pressure-sensitive adhesives are close to Newtonian fluids, and when the viscosity is large, they are generally characterized by pseudoplastics and rheology. In addition, the viscosity of the adhesive can be easily adjusted with solvents as needed, so the coating technology of solution-type pressure-sensitive adhesives is generally easy to master. However, for cross-linked solvent-sensitive adhesives, if the polymer has been partially cross-linked before coating, the glue will have an obvious Weissenberg effect (that is, the elastic effect of the polymer melt or concentrated solution, because a part of the energy acting on the system is stored in the form of recovery energy), which brings great difficulties to the coating operation. In severe cross-linking, gels can appear in the glue: particles or even small pieces, making the coating impossible.

(2) Coating performance and process of emulsion pressure-sensitive adhesive

The coating performance of emulsion-type pressure-sensitive adhesive is relatively complex, so its coating technology is not easy to master, and various problems often occur during the coating process. First, the rheological properties of polymer emulsions are more likely to deviate from Newtonian fluids than those of dissolution. Emulsion hydraulitizers exhibit expansive properties and can appear in a wide range of emulsion particle sizes. Even emulsions that exhibit pseudoplastic properties often show thixotropy when the viscosity is too high, resulting in a decrease in the leveling of the adhesive line. Secondly, the viscosity of the emulsion is generally small, and it needs to be thickened before it can be suitable for coating requirements. Different thickeners can often obtain thickened emulsions with different rheological properties even if they are used for the same emulsion, which is suitable for the requirements of different applicators. For example, the effects of different acrylic acid modulators on the coating performance of emulsion hydraulic adhesive have been studied, and the results show that the non-drawn buttery thickened emulsion hydraulic adhesive can be obtained with AcrysolASE 60, which is suitable for coating with a reversible roller applicator. The thickener can be used AcrysolASE_95 thickening emulsion hydraulic sensitive adhesive that can be drawn, which is more suitable for coating with gravure roller applicator; If an air scraper applicator is used, both thickeners can be used. In addition, the viscosity of the emulsion changes during storage when thickened with ammonia, which complicates the application process of emulsion sensitive adhesives. Thirdly, the surface tension of the emulsion is high, and the wettability on the surface of the plastic film substrate is poor, and the emulsion coating will produce a "shrinkage" phenomenon when coating, and it is not easy to obtain a uniform and smooth adhesive layer. The addition of wetting agent to the emulsion reduces the surface tension and improves its wetting ability to the substrate. However, the polyene film still needs to be treated for electric years to ensure that the adhesive film has sufficient anchoring effect after drying. When coating silicone barrier paper, "shrinkage" occurs even when a wetting agent emulsion is added. In this case, the problem can only be solved by increasing the viscosity appropriately. In addition, the calculation of the shear speed also has an effect on the wetting effect, the higher the shear speed, the easier it is to wet, so the small coating speed requires the emulsion to have a greater viscosity. Fourth, the emulsion is more likely to produce foam when applied at high speed, so that the surface of the dried adhesive layer cannot be smooth and uniform. The addition of a defoamer can reduce the tendency for foam to form, but adding too much can impair the flow of the emulsion and cause the coating to "pit". Fifth, high shear force, dry surface of the film, and crusting of the emulsion in the air will cause the emulsion to produce clots, which will cause "streaks" during coating or remain in the adhesive layer to make the printing process difficult in the future. Therefore, when these small clots appear, the emulsion needs to be filtered again, in order to prevent the emulsion from crusting, the container needs to be capped, and the emulsion needs to be kept in motion on the coater all the time, even when the machine is temporarily stopped, rollers, pumps, filters, etc. are not recommended.

(3) Coating performance and process of hot-melt and calendered pressure-sensitive adhesives

The rheological properties of the melt of the hot-melt pressure sensitive adhesive are similar to those of the solution pressure sensitive adhesive in principle, but the viscosity of the melt is generally much greater than that of the pressure sensitive adhesive solution. Because pressure-sensitive adhesives are prone to oxidation and deterioration at high temperatures, and their viscosity is high, they need to be coated on a specially designed coating machine. Controlling the coating operating temperature to ensure that the pressure sensitive adhesive has the appropriate melt viscosity and to prevent the pressure sensitive adhesive from oxidizing is the hot melt pressure sensitive adhesive coating processcompareTwo important things.

The calendering paste overcoating process uses the heat and pressure of the calender roller to form a solid pressure-sensitive adhesive layer into a thin sheet and laminate it on the substrate, which is mainly suitable for the coating of calendered pressure-sensitive adhesive with recycled rubber as the main body. Controlling the temperature, pressure and speed ratio of the roller is the key to the coating process, and the substrate used is mainly cloth with high strength and rough surface, and the pressure-sensitive adhesive layer is generally thick. Therefore, it is mainly used to manufacture adhesive products such as cloth adhesive tape, medical eraser books and various medical pastes.

Coating method and industry of pressure-sensitive breaker

There are three basic coating methods of pressure-sensitive adhesive: (1) the method of coating pressure-sensitive adhesive on the substrate is called practical coating method; (2) The coating method of limiting the coating amount of pressure-sensitive adhesive is called quantitative coating method; (3) The method that can make the surface of the pressure-sensitive adhesive layer smooth and uniform is called the uniform coating method. The latter two are generally used in industry.

The quantitative coating method is divided into the prescribed coating method (or pre-quantitative coating method) and the over-coating method (or post-quantitative coating method). The thickness of the adhesive layer coated by the former is uniform, but the flatness is affected by the uneven thickness of the substrate. The latter coats a flat adhesive line, but its thickness is affected by the uneven thickness of the substrate.

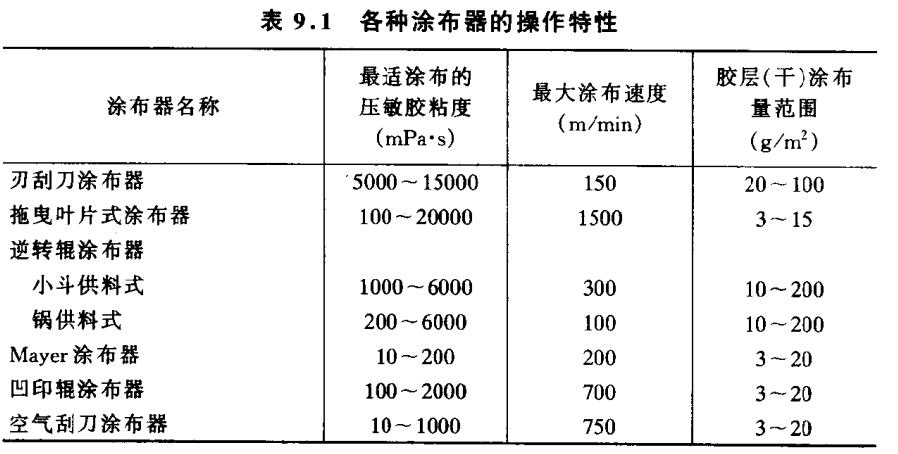

The commonly used coating devices belonging to the pre-quantitative coating method include reverse roller coater, calender roller coater, rod roller coater (or Mayer coater), gravure roller coater, etc.; The commonly used coating devices that belong to the post-quantitative coating method are bladed scraper applicator and various applicators derived from it, such as roller scraper coater, comma roller coater, drag blade coater and so on. The different applicators have different operating characteristics and are suitable for coating pressure-sensitive adhesives of different viscosities, as well as different coating speeds and coating weight ranges, as detailed in Table 9.1. In these applicators,compareIt is important to have two types of blade blade applicators and reverse roller applicators.

1) Blade scraper applicator and its derived applicator

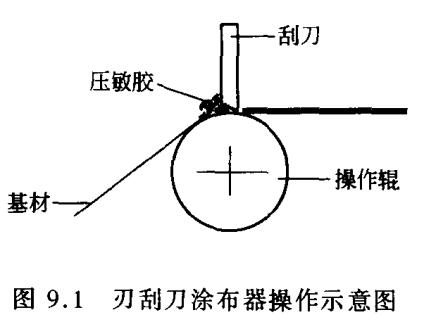

As shown in Figure 9.1, the blade blade applicator uses the gap between the blade of the scraper and the operating roller to adjust the thickness of the adhesive line.

In industry, blade blade applicators are widely used for the coating of solution- and emulsion-based pressure-sensitive adhesives. The advantages are:

(1) The mechanical structure is simple and the cost is low.

(2) It is suitable for coating pressure-sensitive adhesives with a wide range of viscosity, especially high-viscosity adhesives that are difficult to coat with other coaters.

(3) The coating operation is relatively simple and easy to master.

(4) It is convenient to clean the residual liquid and replace the coating solution, so it is widely used in industry.

Its main disadvantages are:

(1) It is easy to be clogged by dirt, undispersed particles or clots, etc.

(2) It is easy to produce large shear stress, especially when coating at high speed, the greater stress will push the scraper away, so it is not easy to coat evenly, and the substrate may be pulled off when it is serious, and even the scraper may be broken.

(3) Even if the shear stress is not large, the thickness of the coating will change with the original existence of the substrate or the uneven thickness caused by the change of tension, so it is necessary to have an accessory device that can easily adjust the thickness.

(4) The bubbles of the coating are not easy to eliminate.

In order to overcome these shortcomings, many different shapes of scrapers have been designed.

The above-mentioned scraper is replaced by a calibrating roller, and the gap between the calibrating roller and the operating roller is adjusted to control the thickness of the adhesive layer, and it can become a roller scraper applicator, and the shear stress generated during coating can also be reduced by adopting the roller scraper applicator, but sometimes the so-called "tailing" phenomenon occurs, therefore, it is not easy to coat evenly, and this applicator is suitable for coating high-viscosity glue and thicker coating.

The calibrating roller in the roller scraper applicator is replaced with a comma roller, which becomes a comma roller applicator, which has the characteristics of both blade scraper applicator and roller scraper applicator. The shear stress is smaller than that of the blade scraper applicator, the coating thickness can be adjusted, the high viscosity glue can be applied, and the width can be adjusted laterally, and the comma roller applicator can also be applied to the reverse roller applicator.

The dragging blade coater is to use a relatively soft blade instead of a squeegee with a very stiff scraper, dragging the coating device that scrapes the glue on the substrate, and can also be coated with a roller scraper applicator first, and then use the scraping of the dragging blade to control the thickness of the adhesive layer, this kind of coatercompareIt is suitable for high-speed coating of thin layer barrier agents.

(2) Reverse roller applicator

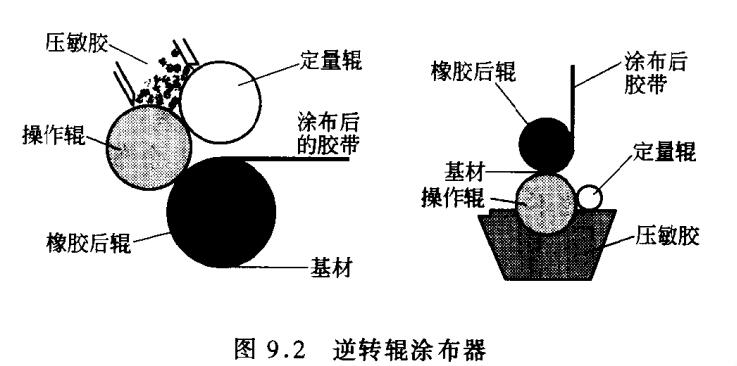

This is another important type of coater in the industry, which is widely used for the coating of solution, emulsion and hot melt pressure sensitive adhesives. There are two commonly used types: three-roller small bucket feeding type and three-roller double feeding type. The former is suitable for applying higher viscosity adhesives; Low-viscosity adhesives that tend to flow out of the gap between the hopper and the baffle should only be applied with the latter.

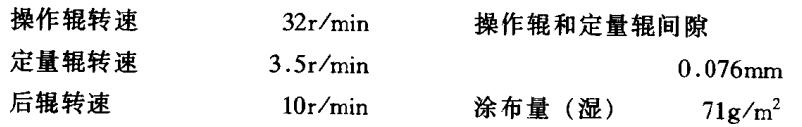

This type of applicator consists of a handling roller, a rear roller and a dosing roller (see Fig. 9.2), the rear roller is made of hard rubber, which supports the back of the substrate and runs in the same direction and speed as the substrate, which can bite the substrate and reduce the tension of the substrate. The operating spokes travel in the opposite direction to the substrate and at a different speed than the substrate and can be adjusted according to the rheological properties of the pressure-sensitive adhesive. Therefore, the adhesive with different properties can be accurately and evenly coated, not affected by the tension of the substrate, and the thickness of the adhesive line can be accurately controlled by adjusting the interval between the dosing roller and the operating roller or changing the speed of the dosing report. In order to reduce the blockage of the coating solution, the dosing roller and the operating roller are slowly rotated in the same direction or in the opposite direction, and the surface of the dosing roller is continuously scraped with a soft scraper attached to the roller, and the speed ratio of the operating roller and the rear roller and the speed ratio of the operating roller and the quantitative pori are determined according to the rheological characteristics of the pressure-sensitive adhesive and the specific requirements for the pressure-sensitive tape. This is very important. For the coating of emulsion-type acrylic pressure sensitive adhesives, typical reversing roller applicators are used under the following operating conditions:

It can be seen that the reverse roller applicator not only overcomes the main shortcomings of the blade blade applicator, but also maintains a wide range of viscosity that can be coated, easy adjustment of coating thickness, and easy operation

Advantages, of course, are more complex and expensive than bladed scraper applicators.

In addition to the above-mentioned three-spoke type, there are also various reverse roller applicators with different configurations, such as four-roller type, three-roller pressure type, and two-roller type, which can be adapted to different requirements.

(3) Gravure roller applicator and pressure roller applicator

These two applicators are mainly used for the smooth coating of thin surfaces of low-viscosity glues such as primers and release agents.

Gravure roller coater is composed of a dipping roller and a conveyor roller, the surface of the dipping roller is engraved with a groove of appropriate shape, the glue that is coated is covered with the groove during operation, and the excess glue is scraped off at the same time, and the amount of coating is different due to the shape of the concave, the depth and the angle of the scraper, and the thickness of the coating needs to be changed, but only the concentration of the coating solution can be changed.

Most rod roller applicators are constructed with piano wire spirally wound tightly on the rod roller, and the thickness of the piano wire determines the amount of coating required, so this kind of rod roller coater is also called wire winding roller or Mayer roller coater. Although the rod roller applicator can also be used alone for the coating of glue, it is generally used in conjunction with other applicators to quantify and scrape the coating layer. For example, when the anastomosis roller is used for plane coating, in order to control the thickness of the coating and obtain a smooth surface, the rod roller applicator is commonly used, and according to the calculation, the thickness of the wet glue layer coated with this wire winding roller applicator is about 0.2L45R, where R is the radius of the copper piano wire used, industriallycompareThe diameter of the commonly used piano wire is 0.076~0.64mm.

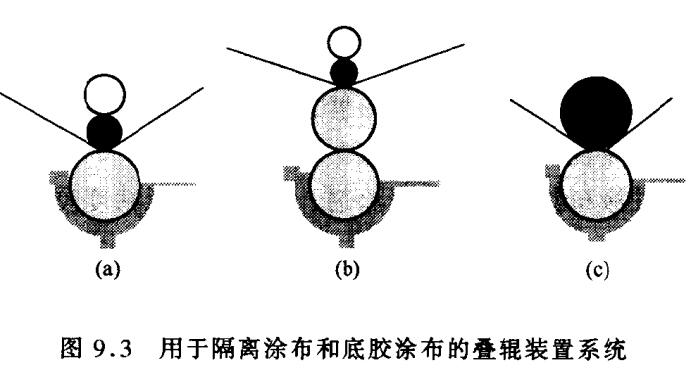

(4) Stacking roller applicator

Before the 80s of the 20th century, gravure roller applicators were generally used for the coating of height separators and primers, but now the volume roller applicator (ACCV_Gravur_system) can be used, see Figure 9.3.

As a third-generation device, this II-roll applicator has the following features for solvent-containing adhesives.

When the working catch is more than 250m/min, the coated rubber material does not contain bubbles; It can be coated with rubber compounds with high solid content; It also has good performance for the thinnest coatings; If due to the selection of the wrong drum seam E; or misoperation caused by the squeegee sewing, there will be no increase in the amount of material supplied here (important for explosion protection).Compared with general applicators, solvent can be reduced by 1/3~l/6.

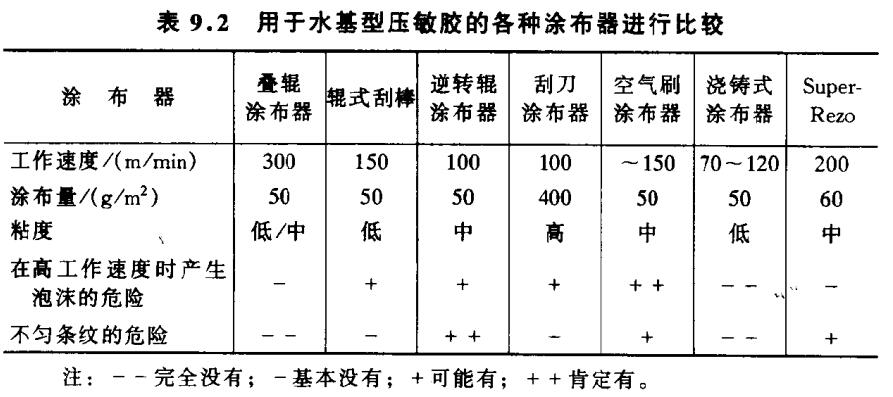

The roller applicator is the only coating system for water-based pressure-sensitive adhesives with a production speed of more than 200 m/min. Comparison of various applicators of water-based pressure-sensitive adhesives,

(5) Calender paste compound coater

These applicators are designed to apply solvent-free pressure-sensitive adhesives such as recycled rubber pressure sensitive adhesives. The adhesive is thoroughly mixed in the mixer, then preheated on a two-roller mill, and then fed into a calender applicator between the top spoke, which rotates slowly to maintain a high temperature (127 °C), and the operating roller, which rotates rapidly to maintain a lower temperature (38 °C), and extrudes the rubber from the gap between the two rollers due to the pressure of the two rollers softening and reverse rotation, and the softened rubber flakes further meet the substrate in the gap between the operating rollers and the bottom roller that maintains a medium temperature (93 °C). Due to the high temperature of the substrate and the pressure of the two rollers, the rubber flakes are laminated together with the substrate to form a pressure-sensitive tape. Due to the low surface temperature of the operating rollers, the resulting pressure-sensitive tape can be completely disengaged from the operating rollers.

When coating with this applicator, the substrate has a high tension, so it is only suitable for coating substrates that can withstand high tension, such as cloth or other fabrics. In addition, only a thick coating can be applied, and it is difficult to apply evenly when the thickness of the adhesive layer is less than 0.lmm. Therefore, this type of applicatorcompareIt is suitable for the manufacture of medical erasers and other medical pressure-sensitive tapes, and is also suitable for the manufacture of polyethylene pressure-sensitive tapes for some anti-corrosion. Pressure-sensitive adhesive and polyethylene can be calendered directly on a three-roller calender applicator or directly applied to a fabric-based substrate directly on a four-roller calender applicator.

(6) Applicator suitable for hot-melt pressure-sensitive adhesive

With the development of hot-melt pressure-sensitive adhesives, this kind of coater has gradually developed, and the coaters suitable for hot-melt pressure-sensitive adhesives in the industry mainly include roller coaters, jet slit coaters and extrusion coaters.

The gravure roller applicator and the reverse roller applicator described earlier can both be used for the application of hot melt pressure sensitive adhesives, but they are only suitable for coating hot melt pressure sensitive adhesives with low melt viscosity. The new generation of Hori-coated applicators is capable of applying hot melt pressure sensitive adhesives with a melt viscosity of up to 200 Pa·s. The principle of operation of this applicator is similar to that of a calender compound applicator, because the rotation of the A-roller lifts the molten pressure-sensitive tape and recombines it with the substrate in the gap of the C-roller; The B-roller rotates very slowly and actually only acts as a dosing roller. Since the travel speed of the substrate is much greater than the surface velocity of the A roller, even the adhesive with a high viscosity can be coated relatively evenly, and the disadvantage of the roller coater is that the glue is directly exposed to the air, which is easy to cause thermal and oxidative aging, which changes the performance of the pressure-sensitive adhesive.

The narrow-base applicator is closed, and the molten pressure sensitive adhesive is fed through a narrow gap to the moving substrate without direct contact with the air. There are two kinds of slit applicators: __ kind of slot applicator, the slit that transports the adhesive is on the top of the substrate, and the adhesive only relies on its own gravity to flow from the slit like a thin cord to the moving substrate to achieve the purpose of coating; The other is called the jet slit applicator, the slit that transports the adhesive is under the substrate, and the adhesive is sprayed to the moving substrate through the slit by the pressure of the pump, obviously, the former can only apply the pressure sensitive adhesive with small viscosity, and the latter can apply the adhesive with a large melt viscosity (up to 200pa·s) due to the high pressure of the pump. For this reason, jet narrow bell applicators are commonly used in industry. The disadvantage of this type of applicator is that it is easy to get clogged with curds and impurities, and it is cumbersome to clean and change the adhesive.

The extrusion applicator is a primordial extruder that delivers molten pressure-sensitive adhesive to the substrate and is therefore also a closed type with no oxidation of the adhesive. Obviously, the screw extruder is one of the key equipment, the components of the pressure-sensitive adhesive are mixed in the extruder while moving forward, and heating and melting at the same time, because the adhesive is easy to stick to the blades of the screw, the general plastic extruder is not applicable here, for this purpose a special screw extruder has been developed, this extruder is equipped with an auxiliary cleaning medium rod in the front of the raw material mixing part, which can continuously remove any material that may stick to the main screw. In order for the components of the adhesive to be well mixed, the extruder needs to be designed to be long and thin enough, with a length-to-diameter ratio of about 40:l. Since mixing, melting and extrusion are done in a single pass in the screw extruder, the total residence time of the pressure-sensitive adhesive in the extruder is only a few minutes, and the time at high temperatures is even shorter, so the thermal decomposition problem is not serious. With this coater, the viscosity of the adhesive that can be applied is wider than that of the first two types of coaters, and even the pressure sensitive adhesive with a melt viscosity of 20~2000pa·s can be coated. In addition, this type of applicator does not require the substrate to withstand high temperatures, so it is very promising to use it to coat plastic substrates such as polyvinyl chloride and polypropylene.

- 1High-low temperature resistance test solution for pressure sensitive tape

- 2Application of Film Applicator in Pressure sensitive adhesive film

- 3Composition material of pressure sensitive tape

- 4Pressure sensitive adhesive performance test overview

- 5Coating Spreader Process Introduction A roller painting

- 6Coating Spreader Method - Coating

- 7Coating Spreader dipping

- 8Coating Spreader Method One Brush

- 9Pressure sensitive adhesive type