Corrugated core flat compressive strength (CMT) test

Test Principle

The flat crush strength of the corrugated core refers to the corrugated core paper pressed into a certain shape of corrugation on a certain tooth-shaped flute instrument at a certain temperature, and then the maximum pressure that the corrugated core can withstand is measured on a compression Tester. The unit is N said. The test equipment adopts a compression Tester and a corrugated core flute meter, and the corrugated core paper is made into a corrugated core by using the corrugated core flute meter. The compression Tester can utilize a spring plate type compression Tester or a sensor type compression Tester.

Test Methods

The test is carried out according to the national standard GB 2679.6 "Measurement method of flat compressive strength of corrugated core". The specific test steps are as follows.

a. Sample collection and processing. Sampling according to GB450, cut along the paper width (12.7 ± 0.1) mm, length of at least (152 ± 0.5) mm (longitudinal) several samples of the sample. According to the requirements of GB 10739, carry out temperature and humidity pretreatment on the samples.

b. Start the corrugated core flute Tester, pre-heat to (177 ± 5) ℃, and then insert the sample vertically into the corrugated spoke wheel to make a corrugated core sample. The corrugated core sample is then placed on the comb, and the comb teeth are pressed against the sample.

c. Use an adhesive tape about 120mm long to place on the flute peak of the corrugated core sample, and then press the flat plate to fix the corrugated shape. Gently take out the comb teeth, remove the corrugated core sample from the rack, and place it flat on the center of the lower platen of the compression instrument, with the side without the adhesive tape facing up. Start the compression Tester, crush the corrugated core sample, read the value on the Recorder, and obtain the flat compressive strength of the corrugated core. If necessary, the corrugated core sample can also be placed under constant temperature and humidity conditions for 30 minutes, and then the compression test is carried out. If the surface of the upper and lower platens of the compression Tester is smooth, the upper and lower platens should be covered with fine emery cloth to prevent sliding during corrugation. During the test, if the tape comes off or the corrugation is pushed to one side, the test shall be repeated.

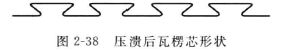

The shape of the corrugated core after being crushed is shown in Figure 2-38. The test results are expressed as the arithmetic mean of all measured values, accurate to 1N, and the maximum and minimum values are reported.