How is corrugated cardboard edge compression strength (ECT) tested?

Test Principle

Place a rectangular corrugated cardboard sample between the two pressure plates of the compressive strength Tester, and make the corrugated direction of the sample perpendicular to the two pressure plates of the instrument, and then apply pressure to the sample until the sample is crushed. The unit is expressed in N/m. The compressive strength Tester can use a spring plate type compression Tester or a sensor type compression Tester.

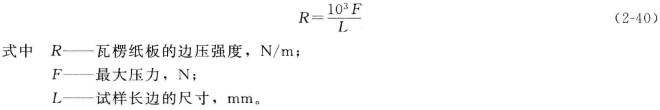

The edge compression strength of corrugated cardboard is:

Test Methods

The test is carried out in accordance with the national standard GB 6546 "Determination of edge crush strength of corrugated cardboard", which is suitable for the determination of single corrugated cardboard, double corrugated cardboard and triple corrugated cardboard. The specific test steps include the following points.

a. Sample collection and processing. Sampling according to GB 450, cut 10 rectangular samples along the paper web, the sample size is (25 ± 0.5) mm on the short side, (100 ± 0.5) mm on the long side, and the short side is along the corrugated direction. Due to the large thickness of corrugated cardboard, it is easy to deform under pressure, which will change the shape of the corrugated core in the middle, resulting in large errors in test results . the edge of. According to the requirements of GB10739, carry out temperature and humidity pretreatment on the samples.

b. Wrap the upper and lower pressing plates of the compression Tester evenly with fine emery cloth, and keep the upper and lower pressing plates parallel.

c. Place the sample at the center of the lower platen of the compression Tester, clamp it with a guide plate, and keep the corrugated direction of the sample perpendicular to the plane of the lower plate.

d. Start the compression Tester and apply pressure to the sample. When the pressure is about 50N, remove the guide plate and continue to apply pressure until the sample is crushed. Read the value displayed on the instrument, that is, the maximum pressure value that the sample can withstand. Accurate to 1N.

e. Restore the upper platen and prepare for the next test.

f. Calculate the edge compressive strength of corrugated cardboard.

The test results represent the edge compressive strength of the sample as the arithmetic mean of 10 tests, accurate to 100N/m.

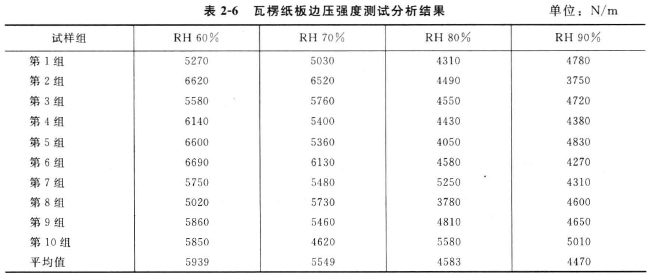

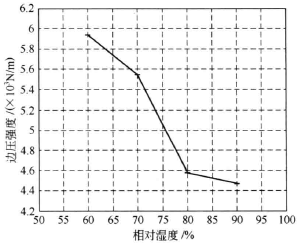

For example, for AB type double corrugated cardboard, the surface paper is 300g/m2 kraft paper, and the inner paper and core paper are 180g/m2 corrugated base paper. The test environment temperature is 20°C, and the relative humidity is selected as 60%, 70%, 80%, and 90%, respectively. Table 2-6 and Figure 2-39 show the analysis results of the edge compressive strength test, which show that with the increase of the relative humidity of the environment, the edge compressive strength of the AB type double corrugated cardboard gradually decreases, and the edge compressive strength at 90% relative humidity is The strength is about 24.7% lower than the edge compressive strength with a relative humidity of 60%, which is a large drop. Because the corrugated core layer is similar to the I-beam structure, it can withstand greater pressure. However, as the relative humidity increases, the core paper itself becomes loose and its stability deteriorates, resulting in a significant decrease in edge pressure strength.

Figure 2-39 The relationship curve between edge compressive strength and relative humidity of corrugated cardboard