Clark stiffness Tester test method

The Clark Stiffness Tester expresses the stiffness by the bending degree of the sample under the action of its own weight, and is mainly used to measure the stiffness of paper. Clark stiffness indicates the nature of the sample supporting its own weight, namely:

Clark stiffness=L³/1000

In the formula, L—the length from the center of the chuck to the free end of the sample, mm.

The bending resistance indicates the resistance of the sample to the bending force, namely:

Bending resistance=L³G/1000

In the formula, G —— quantitative quantity of the sample, g/m2.

The bending resistance index indicates the bending resistance inside the sample and the properties of the paper structure, namely:

Bending index=0.1639L³G/1000d³

In the formula, d—thickness of the sample, accurate to 0.01mm.

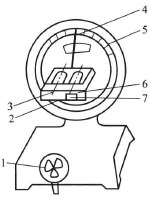

Figure 2-44 Clark Stiffness Tester

1—handle; 2—roller; 3,6—clamp roller; 4—pointer; 5 dial bending angle; 7—worm wheel

The test instrument used to measure the Clark stiffness of paper is a Clark stiffness Tester, as shown in Figure 2-44. The testing method of Clark stiffness is to firstly sample according to GB 450, cut the sample, and pretreat the sample with temperature and humidity according to the requirements of GB 10739. Then insert the 50mm wide sample vertically into the rotary chuck, adjust the length of the sample to make it suitable for measurement, first rotate the chuck slowly clockwise to make it turn through an angle of 90°, and then rotate it counterclockwise Rotate the chuck so that the specimen falls from side to side. Measure the length from the center of the chuck to the free end of the sample, and calculate the Clark stiffness, bending resistance and bending index of the sample.

- 1Precautions and maintenance methods for the use of paper stiffness Tester

- 2Comparison of commonly used stiffness meters

- 3How does the horizontal stiffness meter operate?

- 4Measuring Principle and Method of Taber Stiffness Tester

- 5Test method and principle of Gurley stiffness meter

- 6Taber stiffness test method

-

Yunda YD-TD-B cup stiffness Tester 0-10N$ 2264.00

-

-

-

LD-TD-A-01 Bending Stiffness Tester$ 1691.00

-

CHENCHI ZBT-10 Paper cup Stiffness meter$ 1879.00