Measuring Principle and Method of Taber Stiffness Tester

The Taber stiffness Tester indicates the stiffness of the cardboard by the bending moment when bending a 38mm wide sample to an angle of 15° under certain conditions, and the unit is g-cm (lg·cm=0.098mN·m) or mN·m.

(1) Taber stiffness Tester

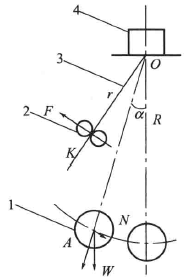

①Structure The Taber stiffness Tester is designed according to the principle of moment balance on the center of the rotating shaft, as shown in Figure 2-46, it is expressed by the bending moment when bending a 38mm wide sample to an angle of 15°, and is mainly used for cardboard stiffness determination. The load dial is engraved according to the sinusoidal function relationship, which represents the sinusoidal function relationship of the torque. The scale is engraved according to the 1mm wide sample and 10g weight, indicating the bending moment. The angle plate rotates with the main shaft, the upper edge has 7.5°, 15° angle engraved lines, the lower part is equipped with a paper pusher, and the paper pusher is installed on the pusher. The vertical distance between the center line of the two rollers and the rotation center is 50mm . When the angle disc rotates, the paper pusher rotates together with it, and the circular roller pushes the sample, giving the sample a bending force and generating a bending moment. The rotation speed of the angle plate is to rotate 200° ± 2° per minute. The straight line of the lower edge of the clamp jaw should coincide with the center of rotation, and the distance from the center of rotation to the center of the lower weight is 100mm. The paper gripper is installed on the load pendulum. There is a balance jack on the upper part and a small shaft on the lower part. Its weight is 0.098N, which replaces the first-level weight. The small shaft can be equipped with weights of 0.49N, 0.98N, and 1.96N. The pendulum can swing freely on the shaft, and the arm length of the pendulum is (100 ± 0.2) mm. The diameter of the small round roller is (8.60 ± 0.05) mm, and it can adjust the spacing.

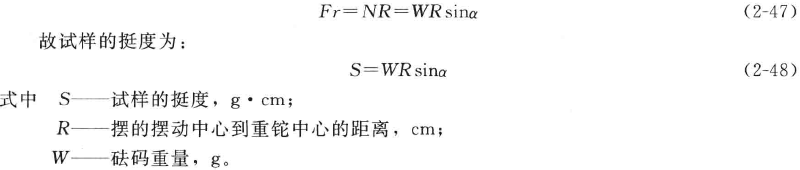

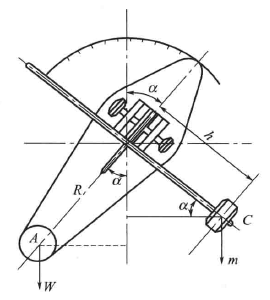

Figure 2-46 Taber Stiffness Tester Figure 2-47 Working Principle of Taber Stiffness Tester

1—load dial; 2—angle plate; 3—sample clamp; 4—load pendulum; 5—small round wheel; 6—heavy thallium; 7—switch 1—pendulum; 2—small round stick; 3—sample ;4—paper clamp

②Working principle When the angle plate rotates, the small round roller starts to move, the paper clips on the pendulum, and the pendulum also rotates accordingly. Two forces with different directions and sizes act on one center of rotation, as shown in Figure 2-47, the moment produced by the two forces F and N on the center of rotation is balanced , the radius of rotation of the loaded weight is OA=R, and the small circular roller The radius of action of the bending moment applied to the specimen OK=r. Before the instrument is started, the sample is not subjected to the bending moment, and the pendulum is in a vertical position due to the gravity of the weight.

When the turntable of the instrument is turned on, the angle disk rotates clockwise, and the sample begins to be bent in the same direction as the circular spokes under the action of bending moment. Since the sample has bending stiffness, the paper clip and the weight spindle rotate to the OA position, and the small round kun stops when it rotates to the OK position. At this time, the sample is in a state of moment balance, namely:

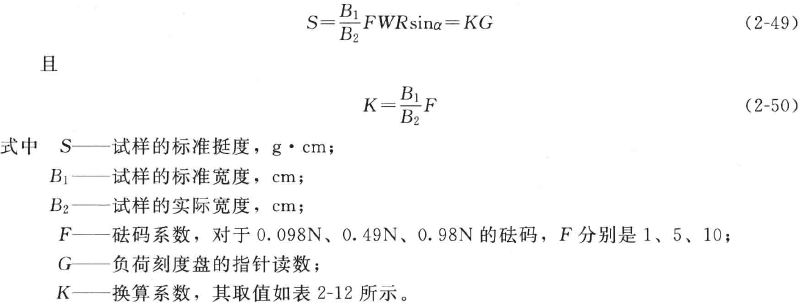

The Taber stiffness Tester is designed with the sample width lcm as the standard width, and the angle of 15° is the measurement constant, that is, a 0.098N weight is added to the pendulum. Take a sample with a width of 1 cm for measurement. When the sample is bent to an angle of 15°, the required torque is the standard stiffness of the sample. The scale of the instrument is calculated according to the standard stiffness condition and the sinusoidal function relationship. However, in the actual test, it is allowed to cut the sample within the range of 15~40mm, and the weight of the weight can also be determined according to the stiffness of the sample, which are 0.49N, 0.98N and 1.96N respectively. In this case, the measured value needs to be converted into standard stiffness. Considering the influence of sample width and weight weight, standard stiffness of sample:

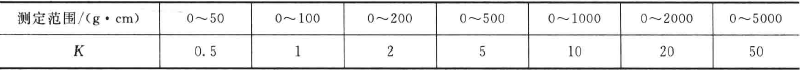

Conversion factor of taber stiffness Tester

③ Calibration procedure

a . The calibration of the load dial accuracy requires no more than ±3% within the range of 10% to 90% of the maximum load. The calibration method is to calibrate with a special force-measuring lever, as shown in Figure 2-48, clamp the special lever in the clamp On the paperware, align the center line, add a weight (weight m) on one side of the lever, and the weight hall can slide on the lever. Slide the heavy blunt to align the zero line of the pendulum to the position of the measured point, and tighten the top wire on the heavy D. Then use a vernier caliper with an accuracy of 0.02mm to measure the distance h, and calculate the stiffness and its error from S=mhcosa, where α is the indexing angle corresponding to a certain scale of the load dial.

b. Check the sensitivity of the pendulum movement, release the pendulum after turning it 15°, and allow it to swing freely. The number of back and forth swings should not be less than 20 times, otherwise find out the reason.

c. Calibration of the rotation speed of the instrument angle disc is measured on the instrument with a stopwatch. The rotation speed of the angle disc should be 200° ± 20° per minute.

Figure 2-48 Principle of special force measuring lever

(2) Test method

The test is carried out according to the national standard GB2679.3 "Determination of Stiffness of Cardboard". The testing instrument is a Taber stiffness Tester. The specific test steps include the following points.

①Sample collection and processing. Sampling according to GB450, cut samples with length (70 ± 1) mm and width (38.0 ± 0.1) mm along the paper web, and no less than 5 samples in the vertical and horizontal directions. According to the requirements of GB 10739, carry out temperature and humidity pretreatment on the samples.

②Adjust the level of the instrument, and then adjust the angle plate, so that the center scale of the pendulum, the zero point of the angle plate and the zero point of the load plate coincide, and then adjust the sensitivity of the pendulum movement.

③Put one end of the sample vertically on the fixing clip, and insert the other end between the two small circles under the instrument , and then fix the sample with the fixing screw, making sure that the sample coincides with the central marking line of the pendulum . Adjust the distance between the sample and the two small round wheels to (0.33 ± 0.03) mm with the small round roller distance adjustment device.

④According to the different stiffness of the sample, select the measurement range by changing the weight blunt, so that the reading of the sample on the load angle disk is between 20°~70°, turn on the switch, and bend the sample to the center line of the pendulum When it coincides with the 15° angle engraved line on the angle plate, turn off the switch immediately, and record the reading of the load dial indicated by the center line of the hem, accurate to half a division. The above operations are carried out in the left and right directions respectively, that is, the readings of the 15° angle of the sample bending to the front and the back are respectively measured. If the specimen is too stiff or breaks when bent to an angle of 15°, it can be bent to an angle of 7.5°. The test result can be multiplied by 2 to get an approximate value, but it should be noted in the report.

⑤ Calculate the stiffness of the sample. The test results are expressed as the arithmetic mean of all measured values in the vertical and horizontal directions, and the settlement results take three significant figures, and report the maximum and minimum values.

- 1Precautions and maintenance methods for the use of paper stiffness Tester

- 2Comparison of commonly used stiffness meters

- 3How does the horizontal stiffness meter operate?

- 4Test method and principle of Gurley stiffness meter

- 5Clark stiffness Tester test method

- 6Taber stiffness test method

-

Yunda YD-TD-B cup stiffness Tester 0-10N$ 2264.00

-

-

-

LD-TD-A-01 Bending Stiffness Tester$ 1691.00

-

CHENCHI ZBT-10 Paper cup Stiffness meter$ 1879.00