MIT refractometer test method

MIT folding endurance refers to the ability of paper or cardboard to withstand 135° reciprocating folding under a certain tension, expressed in the number of reciprocating folding.

(1) MIT folding Tester

①Structure and working principle

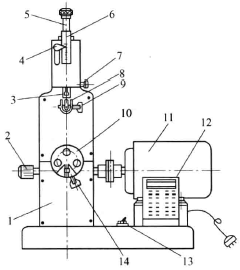

The MIT folding Tester is shown in Figure 1. The sample is folded back and forth 135° under the specified tension condition, and the maximum number of folds when the sample is broken is recorded. The instrument is suitable for measuring the folding endurance of paper and cardboard with a thickness below 1mm.

Figure 1 MIT folding Tester

1-front cover; 2-sample adjustment handle; 3-tension adjustment screw; 4-pointer; 5-tension rod; 6-tension scale; 7-braking screw; 8-upper chuck; 9-holding Screw; 10-folding head; 11-motor; 12-counter; 13-power switch; 14-clamping screw

②Main technical parameters

a. Tension adjustment range: 4.9 ~ 14.7N.

b. Folding angle : 135°±2°.

c. Folding speed : (175 ± 10) times/min.

d. Folding head width : not less than 19mm.

e. Arc radius of fold : (0.38 ± 0.02)mm.

f. The distance of the seam of the folding chuck : 0.25mm, 0.50mm, 0.75mm, 1.00mm.

③ Calibration procedure

It is mainly to calibrate the tension applied to the sample during folding. Add a counterweight to the upper end of the tension rod, and the pointer should indicate the force value of the counterweight. If it does not meet the requirements, you can adjust the tension spring adjustment screw.

In addition, the NZ-135 MIT folding endurance Tester is suitable for measuring the folding endurance of paper, cardboard and other sheet materials with a thickness of less than 1mm. The instrument adopts photoelectric control technology, which can make the folding chuck return automatically after each experiment, which is convenient for the next operation. Its main technical parameters are as follows.

a. Measuring range: 1 to 99999 times.

b. Folding angle: 135°±2°.

c. Folding speed: (175 ± 10) times/min.

d. Tension adjustment range: 4.9~14.7N.

e. The distance of the seam of the folding chuck: 0.25mm, 0.50mm, 0.75mm, 1.00mm.

(2) Test method

The test was carried out in accordance with the national standard GB 2679.5 "Measurement of folding endurance of paper and cardboard (MIT folding endurance Tester)". The testing instrument is the MIT folding Tester. The specific test steps include the following points.

①Sample collection and processing. Sampling according to GB450, cut 8 samples each with a width of (15±0.1) mm and a length of 150 mm along the longitudinal and lateral directions of the paper web, and perform temperature and humidity pretreatment on the samples according to the requirements of GB 10739.

② Calibrate the instrument, adjust the required spring tension, and fix it. Generally, the spring tension required for paper is 1kgf, while that for cardboard is 1kgf or 1.5kgf.

③Choose the folding collet required for the thickness of the sample, clamp the sample vertically between the two clamps of the folding Tester, loosen the spring fixing screw, and observe whether the spring tension pointer points to the position of 1kgf or 1.5kgf. If there is an error, readjust.

④ Start to fold the sample back and forth until the sample breaks, and read the indication number of the calculator, that is, the number of times of reciprocating folding at an angle of 135°. Return the counter to zero for the next test.

The test results are expressed as the arithmetic mean of all the measured values in vertical and horizontal directions, front and back, accurate to integer times, and the maximum and minimum values are reported.

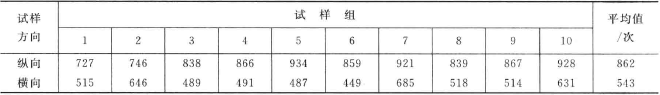

For example, Table 2-14 shows the analysis results of the folding endurance test of Tetra Pak packaging paper/plastic/aluminum composite materials. Due to the influence of fiber arrangement, the longitudinal bonding force is relatively large, and more work is required to break. The longitudinal folding resistance of this composite material is larger than that of the transverse direction, and the mechanical strength is better.

- 1Folding Tester - paper folding performance test

- 2Talking about the application of folding resistance Tester in metal foil

- 3Plastic film folding resistance testing by folding resistance Tester

- 4How is the folding resistance Tester used for the detection of tissue paper?

- 5Analysis on the Application of Folding Tester in Cardboard

- 6What is the folding resistance of paper and cardboard?

- 7What are the factors that affect folding endurance?

- 8Test method and principle of corrugated cardboard folding resistance meter

- 9FRANK horizontal refractometer test method