Test method and principle of corrugated cardboard folding resistance meter

(1) Corrugated cardboard folding Tester

①Structure and working principle

The domestic corrugated cardboard folding Tester is composed of a box body, a transmission system, upper and lower fixtures, and a counter. The transmission principle is shown in Figure 1. The transmission system is driven by the motor at a speed of 130r/min. The crank drives the connecting rod and transmits it to the swing gear, and then the swing gear meshes with the swing head gear to drive the swing head to swing back and forth, so that the upper clamp reciprocates within the range of 135° swing angle. swing. The upper fixture consists of a fixed splint and a movable splint. The upper fixture swings left and right to make the sample reciprocally bend 270°. The lower fixture is connected with the load bar and equipped with weights of different weights, which can make the load reach 3500g. During the test, the tension depends on the sample, and the counter adopts liquid crystal display.

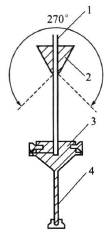

Figure 1 The transmission principle of the corrugated cardboard folding Tester

1- Oscillating gear; 2- Oscillating gear; 3- Crank

②Main technical parameters

a. The maximum swing angle of the upper fixture: 135°.

b. The maximum clamping thickness of the upper and lower clamps : 10mm.

c. Bending speed : 130r/min.

d. The maximum weight of pre-added weight : 3500g.

(2 ) Test method

①Sample collection and processing﹑Sampling according to GB 450, cut 10 samples of 140mm×40mm along the paper width, the size error is ±1mm, the long side is parallel to the corrugated direction, and the short side is perpendicular to the corrugated direction. According to the requirements of GB 10739, carry out temperature and humidity pretreatment on the samples.

Figure 2 The principle of testing the folding endurance of corrugated cardboard

1-sample; 2-upper fixture; 3-lower fixture; 4-load bar

② Clamp the indented corrugated cardboard sample vertically between the upper and lower clamps of the folding Tester, as shown in Figure 2-54. For a single corrugated cardboard sample, the edge of the upper fixture is clamped at a position 3mm away from the centerline of the indentation. For double-corrugated cardboard samples, the edge of the upper fixture is clamped at a position 5mm away from the centerline of the indentation.

③Apply 1500~2500g weight on the load bar of the lower fixture, lift the bottom bracket of the lower fixture, and release it after the sample is clamped, so that the sample is in a tensioned state.

④ Start the instrument and bend the sample through the reciprocating motion of the upper clamp at a speed of 130r/min. The upper fixture is bent from the initial vertical position to the concave surface of the indentation by 135°, then bent by 270° in the opposite direction, and then bent by 135° to the concave surface of the indentation, and then returned to the initial vertical position to complete a 270° reciprocating bending. Figure 3 shows. The sample is subjected to continuous reciprocating bending until the sample is broken. Take the value of the counter, that is, the number of folds of the sample. The counter is cleared and the next test is carried out.

Figure 3 twists and turns

The test results are expressed as the arithmetic mean of all measured values, accurate to integer times, and the maximum and minimum values are reported.

- 1Folding Tester - paper folding performance test

- 2Talking about the application of folding resistance Tester in metal foil

- 3Plastic film folding resistance testing by folding resistance Tester

- 4How is the folding resistance Tester used for the detection of tissue paper?

- 5Analysis on the Application of Folding Tester in Cardboard

- 6What is the folding resistance of paper and cardboard?

- 7What are the factors that affect folding endurance?

- 8FRANK horizontal refractometer test method

- 9MIT refractometer test method