Elmandorf single tearing meter test method

(1) Elmandorf single tear Tester

①Structure and working principle

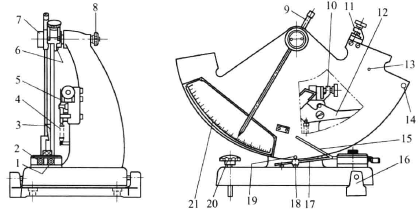

The Elmandorf single tear Tester is suitable for measuring the internal tearing degree of paper and cardboard. It will pre-cut a slit sample and tear it into two halves when the pendulum is released. The tearing degree is measured by the potential energy consumed by the pendulum. As shown in Figure 1. The tearing potential energy is stored by the pendulum around the center of gyration above the frame when its center of gravity is lifted. When the pendulum swings to the left and the right side of the pendulum crosses the center vertical line, it is blocked by the elastic release block below it, so that the sample holders on the pendulum and the sample holders on the frame are both in the state of clamping the sample. When the sample is clamped and the crack is cut with the cutter equipped on the instrument, the elastic release stopper can be pressed to release the potential energy of the pendulum and apply tearing force to the sample. When the sample is torn into two halves, the pointer stops at a certain position on the upper scale, and the scale value is read to calculate the tearing degree of the sample.

Figure 1 Elmandorf single tear Tester

1,2—regulator; 3,9,15—pointer and locator; 4—spring; 5,12 cutter and handle; 6,8—nut; 10,11—sample holder; 13—fine adjustment weight Holes; 14, 18, 19 are scalers; 16—retainer; 17—block; 20—adjusting screw; 21—scale

②Main technical parameters

a. Tear measurement range: A# pendulum is 0~1500mN; B# pendulum is 600~3000mN; C# pendulum is 600~7500mN.

b. Pendulum factor: A# pendulum is 2; B# pendulum is 4; C# pendulum is 8.

③ Calibration procedure

a. When installing the calibration pendulum, do not damage the journal.

b. Remove the pointer and press the release button of the pendulum by hand. When the pendulum is at rest, the calibration line of the pendulum should be aligned with the calibration line of the frame. If there is a gap, it can be adjusted with the pendulum zero adjuster.

c. The calibration line on the frame should be aligned with the zero calibration line on the right side of the pendulum when the pendulum is in its initial position, and the two sample clamps should be flush. If the sample holder is not level, use the sample holder adjuster to adjust.

d. The pointer should be turned to the initial position.

e. Quickly press the release button, and hold it still until the pendulum swings back. At this time, the pointer should indicate the zero scale of the scale.

(2) Test method

The test is carried out according to the national standard GB455 "Determination of tearing degree of paper and cardboard". The testing instrument is an Elmandorf tear Tester. The specific test steps are as follows.

①Sample collection and processing. Sampling according to GB450, for the test of single tearing degree, cut enough paper samples (calculated according to 10 tests, 4 or 8 sheets each time), mark the vertical and horizontal, and cut it into a sample of 63mm×75mm size. The tested direction of the sample should be parallel to the short side. According to the requirements of GB 10739, carry out temperature and humidity pretreatment on the samples.

② Select a suitable pendulum so that the measured value falls within the range of 20% to 60% of the full scale as much as possible. After a comprehensive inspection of the instrument, clamp the cut sample horizontally in two clamps, and place the front and back sides of the sample facing the swinging direction of the pendulum. In general, the samples are stacked in 4 layers.

③Use a knife to cut the sample into a 20mm incision (tear length is 43mm), move the pointer to the pointer limiter, press down the pendulum limiter, make the pendulum drop and tear the sample apart. At the moment when the pendulum returns to the starting position, gently grasp the pendulum with your hand and record the pointer reading.

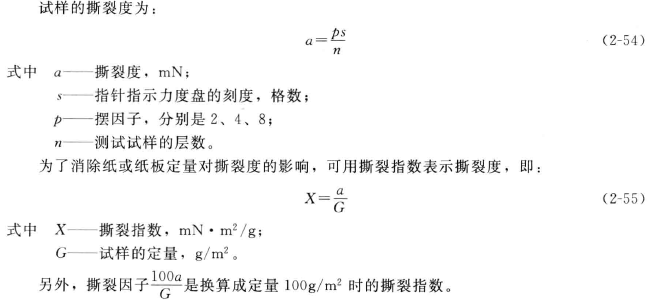

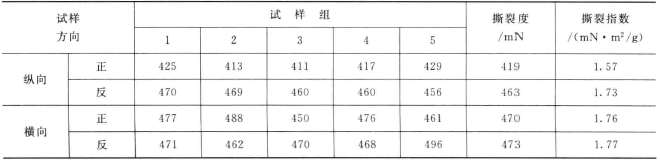

④ During the test, at least 5 tests shall be carried out in the longitudinal and transverse directions respectively. If the sample is deflected when it is torn, and the end of the tear line and the extended line of the knife edge deviate more than 10mm left and right, the result should be discarded. If more than half of the samples exceed 10 mm, all test results are averaged. If the test results of the 4-layer sample are too large or too small, the number of layers can be appropriately reduced or increased. Generally, 2 layers, 4 layers, 8 layers, and 16 layers are used. The test results are expressed as the tear degree and tear index by the arithmetic mean value of all measured values, taking three significant figures.

For example, Table 2-15 shows the tear test analysis results of Tetra Pak paper/plastic/aluminum composite materials. The amount of displacement is large; the tearing displacement of the transverse front is relatively large, while the tearing of the transverse reverse is basically a straight line tear.

- 1Paper tearing determination - Alimendorf method and instrument operation guide

- 2Tear Tester of paper strength

- 3Test method for tensile strength of fabrics

- 4What is tear strength? How to test fabric tear strength?

- 5Brech-Imset Double Tear Tester and Edge Tear Tester Test Method

- 6Test method and principle of LW tearing Tester

- 7What is tearing degree? What are the factors that affect tearing degree?

- 8Paper tear Tester operating instructions

- 9What are the common mechanical performance indicators of paper?