How to test the compressive strength of corrugated boxes and what are the influencing factors?

Main Factors Affecting Compressive Strength

① Base paper performance.

②The edge compressive strength and stiffness of the cardboard.

③ Box structure. When the height of the corrugated box is constant and the peripheral length of the bottom surface changes, different strengths of the corrugated box can be obtained. When the perimeter of a corrugated box is constant, the greater the height, the lower the strength. When the aspect ratio of the corrugated box is in the range of 0.6~0.8, the compressive strength is suitable.

④ circulation environment conditions. Including storage time, ambient humidity and stacking methods.

Compressive strength test

According to the national standard GB4857.4 "Package, transport package, pressure test method", the compression strength . At least 3 corrugated boxes are required for each test. The testing instrument is a pressure testing machine, such as Amsra compression testing machine, ALWEROW CT 30 pressure testing machine, etc. About the structure and working principle, main technical parameters, calibration procedures, etc. of ALWEROW WT 30 pressure testing machine.

Figure 2-60 Corrugated box compression test principle

1-upper platen; 2-carton; 3-lower platen

Before the test, mark each part of the carton sample according to GB 3538, and select a temperature and humidity condition according to GB4857.2, and carry out temperature and humidity pretreatment on the sample for more than 24 hours. During the test, place the corrugated carton at the center of the lower platen, so that the lower platen rises at a constant speed of (12±3) mm/min, as shown in Figure 2-60, the plane of the carton is pressed until it is crushed and deformed, and the meter The reading when the upper pointer stops rotating is the compressive strength of the carton sample. The test results take the average value of all test values as the compressive strength of the carton.

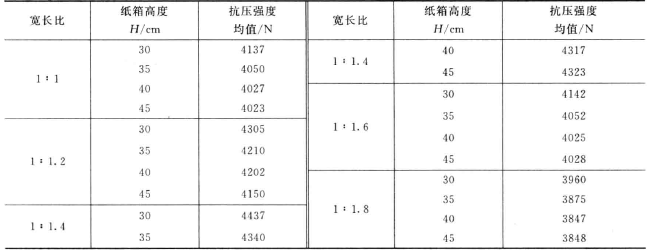

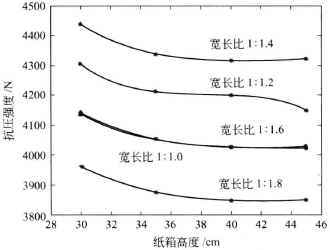

Table 2-17 Compressive strength values of 0201 type BC double corrugated boxes

For example, the sample box is a 0201 type BC double corrugated box, with a fixed perimeter of 160cm, 5 types of width-to-length ratios, and 4 types of heights. The face paper and inner paper of corrugated cardboard are 200g/m2 container board paper, and its ring pressure index is 7.8N m/g, while the core paper is 120g/m2 corrugated base paper, and its ring pressure index is 8.0N m/g. The test environment temperature is 20°C and the relative humidity is 65%. The analysis results of the carton compressive strength test shown in Table 2-17 and Figure 2-61 show that the compressive strength of the carton has a relatively obvious decline from 30 to 35cm in height, and the height of the carton after 35cm has a great influence on the compressive strength. Small, the compressive strength does not change much. When the circumference of the carton is constant, the compressive strength of this kind of carton is higher when the aspect ratio is between 1.3 and 1.5, and reaches the maximum value near the aspect ratio of 1.4.

For another example, Table 2-18 and Figure 2-62 are the analysis results of the flat pressure, side pressure, and top pressure performance tests of the brick-shaped Tetra Pak package produced by paper/plastic/aluminum composite packaging materials. Obviously, this composite packaging box The static compression deformation process of a body consists of three stages, namely, elastic deformation stage, yield stage, and densification stage.

Figure 2-62 Compressive stress-strain curve of brick Tetra Pak packaging

A, B, C, D are data points