What are the compression tests for cartons?

In order to test the pressure resistance of the packaging box and the protection ability of the packaging to the contents, it is usually necessary to simulate the pressure of the carton at the bottom of the stack during the circulation process (such as loading and unloading, transportation, storage) in the laboratory. Factors affecting the compressive strength of cartons include storage time, ambient humidity and stacking methods. According to the national standard GB4857.4 "Package, transport package, pressure test method", the carton compression test is carried out. The test instrument generally uses a pressure testing machine. Before the test, each part of the carton sample should be marked according to GB 3538, and a temperature and humidity condition should be selected according to GB 4857.2, and the temperature and humidity pretreatment should be carried out on the sample for more than 24 hours.

(1) Test principle

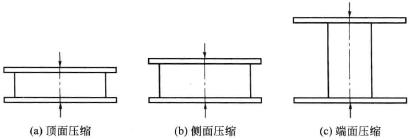

The principle of the carton compression test is the same as that of the corrugated box. As shown in Figure 2-60, the carton is placed between the upper and lower platens of the pressure testing machine. Move the lower platen) to apply a compressive load to the carton. The carton compression test is divided into three types: plane compression test, diagonal compression test and diagonal compression test.

(2) Plane compression test

Take the carton sample that has been regulated by temperature and humidity out of the temperature and humidity control box, and start the pressure test within 5 minutes. The sample is generally placed in the state of normal transportation (the side and end faces can also be subjected to pressure tests) placed at the center of the lower platen so that the upper platen is in contact with the sample, as shown in Figure 2-63.

Figure 2-63 Schematic diagram of carton plane compression test

First apply an initial load of 220N to make the sample in good contact with the upper and lower platens, adjust the recording device, and use this as the starting point for recording. The upper platen moves evenly at a speed of (10±3) mm/min, and is pressed until one of the following situations occurs:

①The compressive load reaches the limit value, and the sample ruptures;

② When the size of the sample changes or the compressive load reaches the predetermined value, the predetermined value is stipulated by the relevant standards, and the package is inspected for damage.

(3) Opposite edge compression test

If it is necessary to test the pressure resistance capacity of the carton, it is necessary to use a pressure testing machine whose upper platen cannot be tilted freely. The depth and angle of the groove shall not affect the compressive strength of the specimen. Before the test, install the metal accessories on the symmetrical positions of the center of the upper and lower pressure plates, so as to ensure that the sample bears pressure along the direction of the opposite edge during the test.

Figure 2-64 Diagonal compression test Figure 2-65 Diagonal compression test

(4) Diagonal compression test

If it is necessary to test the diagonal pressure resistance of the carton, it is necessary to use a pressure testing machine whose upper platen cannot be tilted freely. The test loading method is shown in Figure 2-65. A pair of metal accessories with 120° conical holes must be equipped. The depth of the accessory hole shall not exceed 30mm. Before the test, install the metal accessories on the symmetrical positions of the center of the upper and lower pressure plates, so as to ensure that the sample bears pressure along the diagonal direction during the test.

- 1GBT14907 Standard Indoor Steel Structure Fireproof Coating Performance Testing Scheme [Instrument List]

- 2How to test the compressive strength of corrugated boxes and what are the influencing factors?

- 3What factors will affect the compressive strength of the carton?

- 49 Corrugated Box Test Methods to Ensure Packaging Quality

-

CHINA NBC-600 Carton Compressive Tester$ 1959.00

-

-

CHINA NBC-1000 Carton Compression Tester$ 3011.00

-

-

-