How to install the wire rod applicator in the laboratory automatic coating machine?

Laboratory automatic film coating machines generally use wire rods or scrapers to control the thickness of the coating film. For experimental coating films with thinner coating film thickness, lower sample viscosity or higher precision requirements, wire bar coating is generally selected. The device is used to squeegee. The installation design of the wire rod groove of different equipment is different, but the operation is actually similar. The principle is to fix the wire Bar Coater well and not to roll it during the scraping process, which will affect the coating effect.

This article mainly provides tutorial guidance on how to install the wire rod coater for the domestic wire rod coater, and gives prompts at key nodes to ensure that the coating wire rod is installed correctly.

Let me briefly explain the operation steps first:

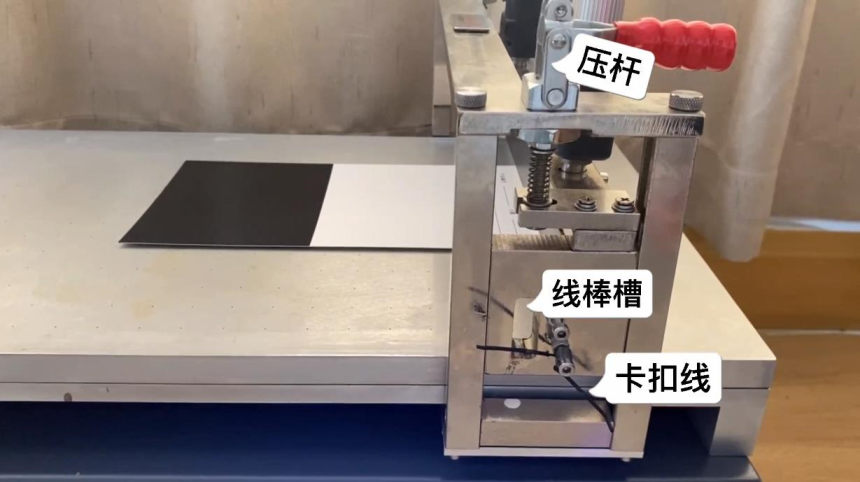

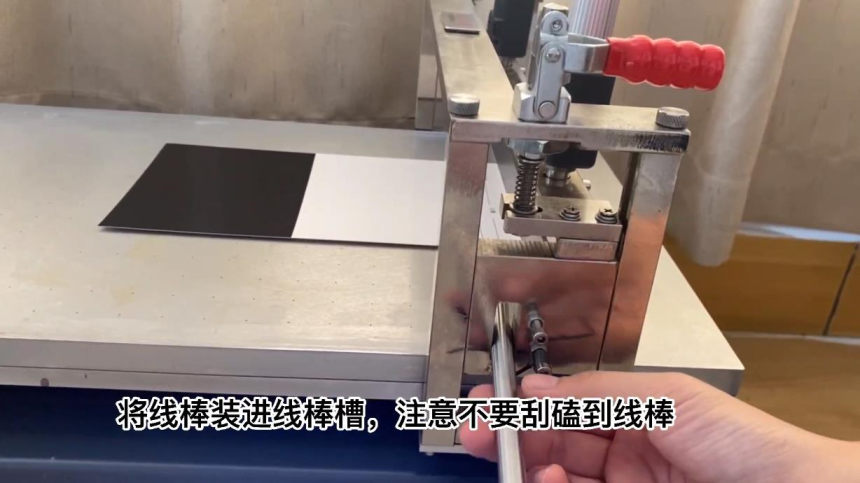

1. Carefully pass the wire rod coater through the wire rod groove, avoid scratching the wire rod winding wire during the process, resulting in broken wire or damage.

2. On both sides of the wire rod groove, respectively press one part of the bayonet wire on the wire rod, and one part buckle the screws on both ends.

3. After confirming that the wire rod will not shake, place it on the pressure rod.

Take a look at the specific operation demonstration video below.

The following intercepts some key video images during the installation of wire rods by the experimental automatic film coating machine.

For more technical knowledge of laboratory coating machines, welcome to communicate with Beichao Technology.

- 1Application of Mayer Rods in protective coating prepative

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 9Application of Automatic Film Applicator in preparing fluorescent diaphragm