Tensile strength test principle and method of plastic film

Experimental principle

The principle of the plastic film tensile strength test is to apply a gradually increasing tensile load in the length direction of the plastic standard sample to deform it until it is destroyed. The maximum tensile stress required for the sample to fail is the tensile strength. The change in the tensile length of the sample is expressed by the elongation at break. On the straight line before the yield point of the stress-strain curve, the elastic modulus of the plastic film can be obtained by selecting appropriate stress and strain.

The tensile strength of the plastic film is:

σt=P/bd

In the formula

σt - the tensile strength of the sample, N/mm2;

P——the maximum tensile load when the sample breaks, N;

b——sample width, mm;

d—thickness of sample, mm.

The elongation at break of the plastic film is:

εt=(ll 0 )/l 0 *100%

Where εt - elongation at break, %;

l 0 - the original gauge length of the sample, mm;

l—the length of the marking line when the sample breaks, mm.

The modulus of elasticity of the plastic film is:

E= σ/ ε

In the formula, E——the modulus of elasticity of the sample, N/mm2;

σ ——tensile stress, N/mm2;

ε ——strain , %.

Test Methods

The test is carried out according to the national standard GB1040 "Test Method for Tensile Properties of Plastics". The test equipment can be an electronic multifunctional testing machine, which is suitable for the tensile strength test of paper, plastic film, composite film, and composite non-metallic materials.

According to the requirements, cut 5 samples along the longitudinal direction and the transverse direction. The shape and size of the samples are shown in Figure 3-19, and process all the samples to balance under the standard environment, and the processing time is not less than 4 hours.

Figure 3-19 Sample shape and size

The specific test methods include the following points.

①Measure the thickness of the sample according to the national standard GB 6672, measure the thickness of each sample at three points within the marking line, and take the arithmetic mean value, accurate to 1um.

② Make a marking line on the parallel part of the sample. This marking line should not affect the test result.

③ Clamp the sample so that the longitudinal axis of the sample coincides with the line connecting the center of the upper and lower clamps of the testing machine, and the tension is appropriate.

④Start the testing machine at the specified speed ((250±50)mm/min) for tensile test.

⑤ After the sample breaks, read the load and the elongation of the marking line spacing. If the specimen breaks somewhere other than the marked line, the test shall be repeated with a new specimen.

⑥ When measuring the elastic modulus, the deformation Recorder should be installed and adjusted to record the load and deformation. Calculate tensile strength, elongation at break, and modulus of elasticity.

Figure 3-20 Tensile stress-strain curve of plastic film

In the actual packaging process, the tensile strength of the plastic film has a limited range. Within this range, the deformed film can return to its original shape. However, if the tensile strength exceeds this range, the deformed film cannot be recovered. Usually, the yield strength is used to affect the service limit of the plastic film, as shown in Figure 3-20, where σ S and σ B represent the yield strength and tensile strength, respectively. Yield strength refers to the tensile force on the sample at the yield point. It is characterized in that the tensile force does not increase significantly during the stretching process of the film, and the stress-strain curve presents a relatively horizontal trend at this time. North and South Chao reminds you: the longitudinal stretch and transverse stretch of plastic film are generally different.

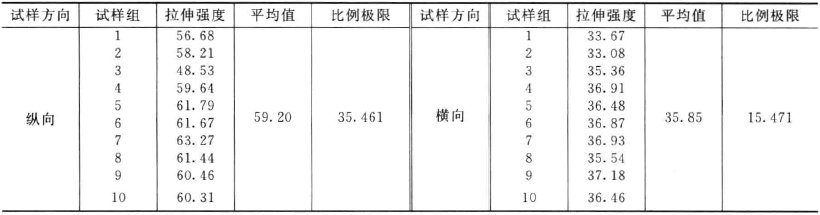

Table 3-6 Analysis results of tensile properties of paper/plastic/aluminum composite materials

For example, Table 3-6 and Figure 3-21 provide the longitudinal and transverse /min, slowly apply a unidirectional load on both ends of the sample until the sample breaks.

Figure 3-21 Comparison of tensile stress-strain curves of paper/plastic/aluminum composites

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines

-

-

-

CHINA NBC-1024-2 Tensile Tester 5T$ 6635.00

-

-

-