Bevel impact test for transport packages

The inclined plane impact test is suitable for evaluating the horizontal impact force that the transport package can withstand and the protection ability of the package for the contents . The principle of the test is: make the sample collide with a baffle perpendicular to the same speed direction at a certain speed according to the predetermined state, and also insert suitable obstacles between the impact surface and edges of the sample to simulate the impact in special situations. under the shock.

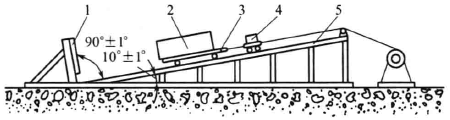

①Incline impact testing machine

It is mainly composed of rails, baffles, trolley mechanisms and release mechanisms, as shown in Figure 6-6. The track consists of two parallel steel rails with an angle of 10°±1° to the horizontal plane, and is installed on the body of the testing machine. The baffle is perpendicular to the track and installed at the bottom of the track. The release mechanism is composed of a roller platen and an electromagnet. It is located at the rear end of the trolley and is controlled by a limit switch to complete the actions of hooking the trolley and the release mechanism, going up, down, stopping, and releasing on the predetermined position of the track. There is a locking mechanism under the baffle. When the package on the trolley collides with the baffle, the locking mechanism will lock the trolley at the predetermined position under the action of the trolley mechanism to prevent the secondary impact from affecting the test results. Impact.

②Test parameters

The instantaneous speed at impact varies with the initial height of the trolley on the track (or the distance the trolley slides). The relationship between the impact speed of the trolley, the sliding distance, and the initial height on the track is:

l=v²/2gsin10°

In the formula, l——the sliding distance of the trolley, l=h/sin10°, m;

v——Instantaneous velocity at the time of impact, m/s;

h - the initial speed of the trolley on the track, m;

g—gravitational acceleration, generally 9.80m/s².

The impact speed can be selected within the range of 1.5m/s, 1.8m/s, 2.2m/s, 2.7m/s, 3.3m/s, 4.0m/s. The basic value of general road transportation is 1.5m/s, and the variation range is 1.5-2.7m/s. The basic value of railway transportation is 1.8m/s, and the variation range is 1.8~4.0m/s. The selection of the range of variation is determined by the transport conditions, quality, and product characteristics of the package.

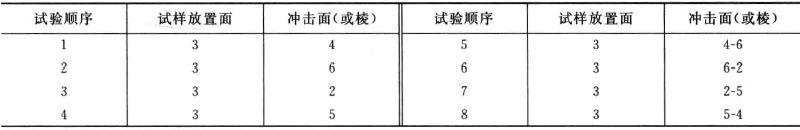

According to product characteristics and transportation conditions, determine the impact surface (or edge ) to be tested , and the number of tests for each impact surface (or edge) is 1 to 4 times, generally 2 times. The test sequence is generally in accordance with the sequence specified in Table 6-4.

Table 6-4 Horizontal impact test sequence

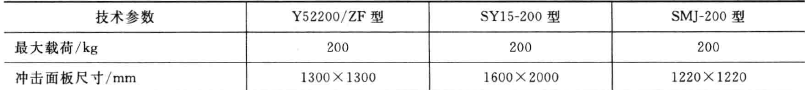

Table 6-5 is the main technical parameters of the inclined plane impact testing machine.

③Test method

The number of samples in each group is generally not less than 3 pieces. Before the test, each part of the sample should be numbered according to GB4857.1, and a condition should be selected according to GB 4857.2 to adjust the temperature and humidity of the sample.

Test according to the national standard GB4857.11 "Packaging and transportation package horizontal impact test method (inclined plane test, pendulum test)". The specific test steps are as follows.

a. Place the sample on the trolley, the impact surface (or edge) of the sample is flush with or protrudes from the front of the trolley, and the distance shall not be greater than 50mm. In the case of surface impact, the angle between the impact surface and the impact surface of the baffle shall not be greater than 2°. When the edge impacts, the angle between the impact edge and the impact surface of the baffle shall not be greater than 2°. If the sample is a parallelepiped, the angle error between one of the two faces forming the edge and the impact surface of the baffle shall not be greater than ±5°, or within ±10% of the predetermined angle (whichever is greater) ).

b. According to the predetermined impact speed, place the trolley on the corresponding position of the track, and then release the trolley to make the sample and the baffle impact. The error of the impact velocity should not be greater than ±5% of the predetermined horizontal impact velocity.

c. After the test, check the damage of the packaging and contents according to the relevant product standards, and analyze the test results.

- 1Application of Pendulum Impact Instrument in Encasement Aluminum Plastic Paper Composite

- 2How to Evaluate Mechanical Properties of Cigarette Pack Aluminized Paper with Pendulum Impact Meter

- 3Application of Pendulum Impact Instrument in Nylon Membrane

- 4Sheet for Pendulum Impact Meter Application

- 5What are the specific applications of pendulum Impact Meter in Plastic film?

- 6General Impact Test for Paints and Coatings - ASTM D2794

- 7Pendulum impact test How to test transport packages?

- 8What is a paper and packaging test instrument? its corresponding standard

- 9Determination of impact resistance of paint film - impact Tester