What is the permeability of ink?

Ink permeability refers to the penetration ability of the ink layer transferred on the surface of the printed sheet, which characterizes the penetration phenomenon and properties of the ink in the early stage of the drying process. In the offset printing process , the penetration process of ink (link material) includes two processes, namely , the instant rapid penetration process at the moment of printing pressure and the slow free penetration .

In the offset printing process, the permeability of printing ink mainly depends on the properties , and is also related to printing pressure, printing speed, the type of paper used, and surface properties (such as ink absorption, smoothness, etc.). 1. The penetration of general ink ink layer on paper shows different penetration properties and penetration speeds due to different types of inks and different viscosities. Usually, the permeability Small.

The permeability of the ink is of great significance to the fixation and drying of the imprinted ink layer and the color reproduction . When the permeability of the ink and the ink absorption of the paper are too strong, it is easy to cause chalking and strike-through, which will significantly reduce the color, gloss and friction resistance of the imprinted ink film; when the permeability of the ink is too high If it is small, it will cause the back of the printed sheet to be dirty (or dirty), and in severe cases, the printed sheets that are piled up will stick to each other .

-

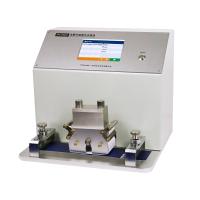

CHINA BLD-PH10 Smoothness Meter$ 1695.00

-

-