Conventional color determination method

(一)宗旨与定义

我们知道,一张印刷品给人最明显的感觉莫过于它的色彩,耶它的鲜艳程度及苌反映的真实性等,也就是说,一张印刷品除了图案的结构外,几乎大多要由颜色来表达。又因有很多印刷厂,每月都印固定的某一种产品,要求油墨的颜色前后一致,否则就会导致印剧品的色彩不一致 etc.。所以,油墨的颜色、色相的检验是非常重要的。

测定油墨颜色的方法主要是将油墨涂布于纸张上后在进行判断比较的。往纸张上涂布的方法则有(1)刮刀刮样法;(2)墨辑辑涂法;(3)用印刷适应性试验仪(或小型印刷机)印刷的方法。至于判断测定的方法则有肉眼判断法和仪器〈如测色计〉测定法两种。所谓肉眼判断法就是凭人的腿睛对标(准)样和试(验)样进行平行观察比较的方法,此法比较简易,但不可能得刭数字上的表示。用仪器法测定则可得到三刺激值,即CIE系统中的主波长、纯度和完度或孟寒尔系统中之色相、彩度(饱和度)和明度等数值。并可以色差数据来表示,所谓色差就是指两个颜色之感觉上的差别以数字形式表示的-种方法。一般都用NBS色差单位表示它们之间的关系 。

本文主要介绍刮刀刮样对比法。因为这种方法比较简易,在工业生产上也已足敷应用了。实际上,从世界范围看来,这种方法仍被普遍地应用着。

(二)器具与材料

1.器具。

(1)小调墨刀。

(2)刮(墨)刀。

(3)玻璃板。

2.材料。

(1)刮样纸。

(2)玻璃板。

(三)方法

用小调墨刀取标准油墨样(下简称标样)和试验油墨样(下简称试样)各少量,分别置于玻璃板上,各将其调匀。然后用小调器刀取标样少许涂抹于刮样纸的左上方处,再取试样少许涂抹于刮样纸的右上方处,二者的位置应相邻近而不相连。

用力使刮刀自上而下将两处油墨在纸上刮成薄层,当刮至5厘米左右黑线以下处时,将刮刀渐渐放平(即使刮刀与纸张所成之角度变小),同时减少用力以使油墨在纸上形成较厚之油器层,在较厚之油墨层上盖上一小片坡璃纸,以免造成污脏。

然后凭i试验以哏睛判断标样与试样在底色、面色及墨色方面的差别。

(四)注意事项

1. Scraping (Drawdown, Pulldown) is one of the main basic skills of ink manufacturers. Thin and fluid inks are easier to scrape, while thick (thick) and viscous inks are not easy to scrape well. If the ink is not good, too thick, short and rough, the scraped shape will be irregular and not smooth (this phenomenon often occurs in engraving gravure ink), which is very ugly.

2. When the blade of the scraper is sharp, the ink layer scraped on the paper is thinner, otherwise, the ink layer scraped is thicker.

3. When scraping relatively thin ink, the angle of the knife can be smaller, so as to ensure that the scraped ink layer is thicker. When scraping thick and sticky ink, the angle of the knife should be larger so that the ink left on the paper is thinner.

4. The quality of the paper has a great influence on the scraping sample. Generally, it is more suitable to use security paper with uniform fiber and smooth surface, or high-grade Dowling paper. The color of the paper should be a neutral white with no fluorescent light and no watermarks.

The International Standard Organization (ISO) recommends that 150 g/m² glossy wood-free paper be used when measuring color, gloss and light fastness. For the determination of gravure and flexographic inks, 140 g/m² wood -free, non-coated high-grade calendered paper is used. These two papers have already been adopted by the National Ink Testing Center.

According to the situation in our country, the size of the scraping paper is about 6.5 x 11.0 cm. It is better to print a black line with a width of about 1 cm at the lower 4 cm to facilitate observation and judgment.

Internationally, the American habit is to place the standard sample on the right and the sample on the left, which is different from ours. According to the concept of smoothness and convenience, we can think that our way of placing is superior.

The size of international scratch-off paper is mostly about 12.5×19 cm (called Standard Drawdown Sheets in the United States), which is about four times larger than that in my country.

5. The content of judging and comparing colors includes three aspects: background color, face color and ink color. When judging the background color of the spot, the scraping paper should be turned away from the light source, and it should be done through the method of perspective. Internationally, undertone generally refers to the color printed on paper by a thin layer of ink. Toptone and Masstone are synonymous, referring to the color reflected by a pile of ink.

In my country, the background color generally refers to the color of the scraped paper with its back to the light source and observed through perspective. Face color refers to the color of thin layer ink observed under normal conditions. Ink color also refers to the color of a pile of ink. However, they do not have a very clear concept, especially between the base color and the face color.

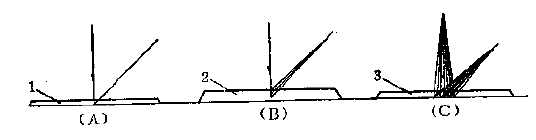

The exact definition of background color, surface color, etc. is: the background color is the color that light reaches the paper through the thin layer of oil, and then reflected by the paper through the thin layer of ink (see Figure A); the surface color is the light that shines on the thick ink layer , the reflection is only produced by the ink (see Figure B); the color is the sum of the base color and the surface color, and the reflection comes from two parts, that is, one part is reflected by the paper through the ink layer after the light passes through the ink layer, and the other Part of it comes from the reflection of the ink (see Figure C).

In the figure, 1. is a thin layer of ink; 2. is a thick layer of ink; 3. is a normal ink layer.

6. When judging and comparing colors, it should generally be carried out under the light of the northern half of the day. It should be pointed out that the light requirements for color work are relatively strict, so as not to cause illusions.

7. In addition to directly scraping the gravure ink for comparison, another method is to put 0.5 grams of ink and 5 grams of standard white ink (can be arbitrarily fixed) on the toner Grinder to grind and mix 150 times (not Add weights), and then compare them by scraping.

8. Solution ink can also be used for scraping comparison in this way.

However, they can also be put into the two grooves of the standard sample and the sample with a double-groove scraper instrument, then scrape it flat with a scraper, then spread a piece of paper, and then use the hand (or rubber roller) to emboss the ink in the groove Compare and judge on paper.

If the sample is scraped on a plastic film: first, a plastic film must be selected, and second, a scraper rod (which can be wound around a metal round rod with a length of about 15 cm and a diameter of 0.5-0.7 mm) It is a steel wire of 0.15-0.17 millimeters, and the width of the winding is about 8 centimeters) instead of a scraper, and the ink layer thickness of the scraped sample scraped by this method is about 30 ± 5 microns.

It is true that for solvent-based inks, the most satisfactory method of color comparison is to use a small printing machine (flexographic letterpress printing machine, gravure printing machine) to print and compare it with a printed sample.

9. Lithographic inks and letterpress inks can also be compared by roller coating on paper. However, the thickness of the ink layer should be strictly controlled (this can be done by putting a certain amount of ink on an area of a certain size, such as a glass plate or a metal plate, and then using a child to coat the oiler (roller) evenly. , the ink on the roller is relatively uniform, and then the ink on the roller is mixed on the paper, and the sample can get a satisfactory result). However, the operation process of this method is relatively complicated, so there are not many adopters.

The more accurate method is to use a printability Tester for printing and then compare and judge with the printed samples. Of course: the method of using a small printing press is not excluded.

10. It is very easy to measure the color by using a color meter (Color Meter). For example, when using a Colorimeter, it only takes a few minutes to calculate the tristimulus value xYz, chromaticity coefficient *.y., total color difference △E, and color difference Lab. and L·a*b· values are determined.

Some countries set the color difference as less than 3 NBS units, which is considered qualified, but this work has not yet been carried out in our country.

- 1Significance and method of INKS surface tension detection

- 2Testing and test methods for performance of different inks

- 3Color and brightness factors for signal testing

- 4Determination of Wear Resistance of Ink Film by Abrasion Meter

- 5Thixotropy - the viscosity of inks and paints

- 6What are the subjects of ink testing for food, pharmaceutical and other packaging?

- 7ASTM Ink Tape Testing

- 8What is the cheese and oil resistance of ink?

- 9How to test the heat resistance of ink?