How to test the dryness of ink by heat drying method?

Apply a thin layer of ink on a non-absorbent substrate, simulate different printing conditions (including temperature and time), and heat it in an electric constant temperature oven to observe the drying of the ink. This method is generally applicable to the dry determination of metal inks, glass inks, and aluminum foil oil-wet products.

(1) Equipment and materials

①Apparatus.

(i) Minor tuner knife.

(ii) Small rubber spokes (preferably those containing rubber).

( iii) Oven.

( iv) Glass plate for ink distribution.

② material. Tinplate sheet, aluminum foil, aluminum sheet or glass sheet, the size is according to the applicable degree. The choice of substrate depends on the type of ink.

(2) method

First adjust the oven to the desired temperature and keep it constant.

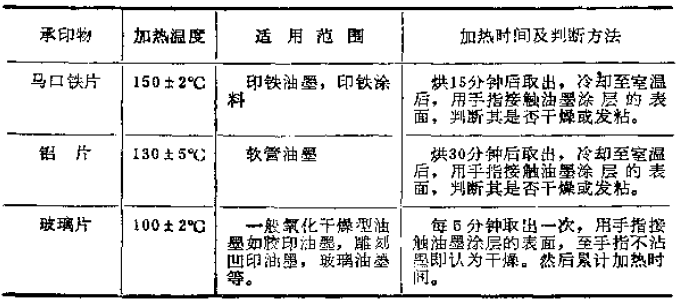

Apply a small amount of the ink to be tested on a small rubber roller, and mix the ink well on a glass plate. When the roller reaches a certain thickness, apply the ink on the rubber to the predetermined substrate. Then put it in a constant temperature oven, and the baking conditions depend on the requirements. The table provides three different situations.

(3) Precautions

①The heating conditions provided in the table below are for reference, and can be specified separately according to the actual application.

② When coating a layer of ink on the substrate, the thickness of the ink layer is the key to the measurement, and it is required to be thin and uniform, which requires rich experience.

③ If the number of times taken out of the oven is too high, the result may be inaccurate. Therefore, the time for taking out can be extended according to the situation, and the number of taking out can be minimized to improve its accuracy.

④ Wear gloves when taking out the substrate from the oven to avoid burns.

- 1Principle, application and selection of Electric Oven

- 2Principle, application and selection of Electric Oven

- 3Principle, application and selection of ozone sterilizing oven

- 4Principle, application and selection of tunnel oven

- 5Working principle and application analysis of laboratory oven

- 6Significance and method of INKS surface tension detection

- 7Testing and test methods for performance of different inks

- 8Hot Air Oven FAQ and its solution

- 9Precision oven FAQ and its solution