What is the specific gravity of ink? How to measure?

(1) Purpose and Definition

The ratio of the weight of the same volume of ink to water at a certain temperature is called the specific gravity of the ink.

Regarding the definition of specific gravity, it is often expressed by D (or d) in some references. The symbol d indicates the ratio of the density of the substance at 25°C to the density of water at 4°C (the density of water at 4°C is exactly equal to 1.000000 g/ml).

Since there is no strict distinction between mass (i.e. density) and weight in industry, simply speaking, the specific gravity of an object is the ratio of its weight to its volume. That is, the weight per unit volume of an object, and its unit is g/cm.

Determining the specific gravity of ink has two purposes, one is to calculate the size of the required packaging container, and the other is to estimate how many prints can be printed (such as printing a book, a ream of paper requires about For drawing, one ream of paper needs about 1 kg of various colored inks). Obviously, when the thickness of the ink layer is the same, the printing number of the ink with a large specificity is relatively small.

Generally speaking, the specific gravity of paste ink is between 1.00-2.25.

(2) Equipment and materials

1. Utensils.

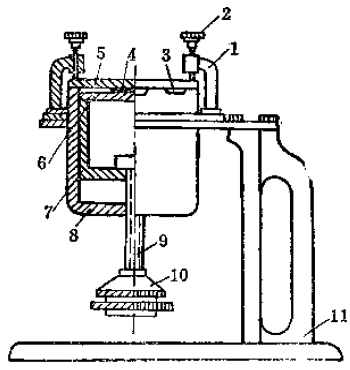

(1) A set of hydrometer, including one piece of upper glass sheet (about 6.8 cm in diameter) and one lower glass sheet (about 6.0 cm in diameter), and two standard steel gaskets with a thickness of 0.3 mm and 0.5 mm respectively. Its brief structure is shown in Figure 27-14 . In the figure 1. Screw bracket; 2. Screws for fixing the upper glass sheet; 3. The groove on the upper edge of the outer cylinder; 4. The ink expanded into a cylindrical shape under pressure; 5. The upper glass sheet; 6. The lower glass sheet; 7. The inner cylinder for raising the lower glass sheet; 8. The outer cylinder; 9. The screw ; 10. The handle; 11. The base and bracket of the instrument.

Figure 27-14 Schematic diagram of the structure of the hydrometer

(2) Transparent measuring ruler with a scale of 60-70 mm.

(3) An analytical balance with an accuracy of one dry part.

(4) Minor Ink Knife.

(3) Method

Use an analytical balance with a precision of one thousandth to weigh 0.3 grams of ink at the center of the lower glass slide. Then the lower glass sheet is placed on the liftable inner circle, and the rotary handle 10 is turned so that the ink surface on the lower glass sheet is lower than the upper edge of the outer cylinder.

Put the upper glass sheet on the edge of the outer cylinder, tighten the screw 2 to fix the upper glass sheet, and at the same time insert steel gaskets into the two corresponding grooves on the upper edge of the outer circle, rotate the knob 10 to raise the inner cylinder, Until the lower glass piece and the upper glass piece just clamp the steel gasket.

At this time, the ink on the downhill glass sheet is squeezed by the two glass sheets and expanded into a column as thick as the gasket. Measure the diameter of the ink circle with a transparent measuring ruler. Ink specific gravity is calculated according to the following formula:

D=W/πr²H

In the formula: D = the specific gravity of the tested ink.

W = the weight of the ink to be tested (ie 0.3 grams).

π = pi, take 3.1416.

r = the radius of the ink circle (centimeters).

H = the height of the cylinder of the oil wall, that is, the thickness of the steel gasket (cm).

(4) Matters needing attention

1. Before weighing, it is best to adjust the ink with a small ink knife, so as to ensure that the expanded oil can be rolled into a round shape.

2. When rotating the handle 10, do not use too much force, so as not to cause the glass sheet to be crushed due to excessive pressure.

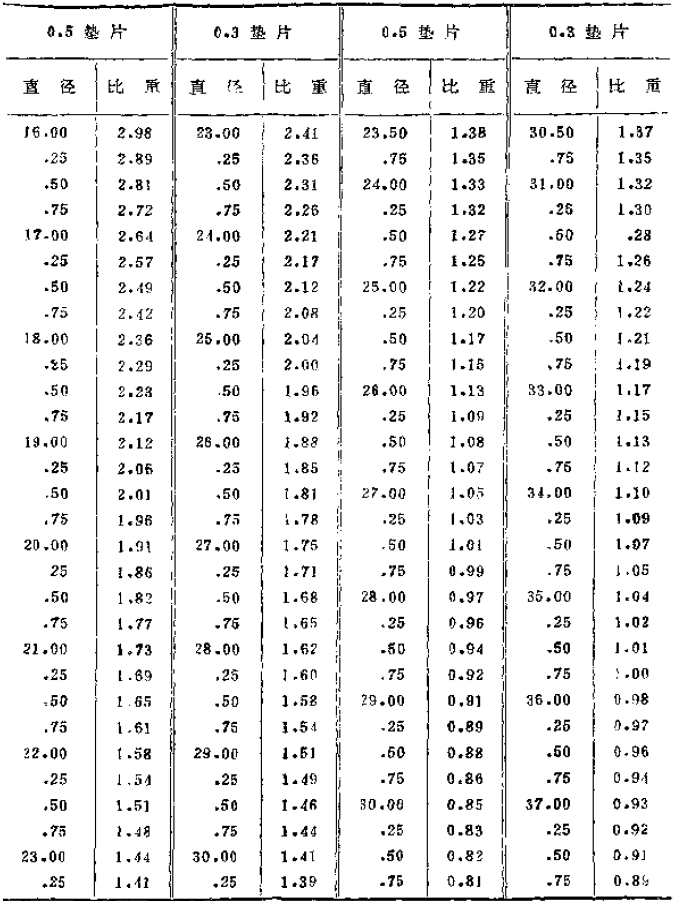

3. When inserting steel gaskets (commonly known as calipers), you can first insert the 0.5 mm one, take it out after the measurement, and then insert the 0.3 mm one. This is equivalent to obtaining two data, which can be checked with each other.

4. When measuring the diameter of the ink circle, the eyes should be observed vertically to reduce measurement errors. Generally, the diameters that are perpendicular to each other are measured at least twice, and when the difference between the two measured results is not more than 2 mm, the average value can be taken; if the difference between the two measured diameters is more than 2 mm, the test needs to be repeated.

5. See Table 27-8 for the conversion table of ink specific gravity.

6. There are many methods for measuring the specific gravity of ink. For example, hydrometer, Webster balance, pycnometer, etc. can be used for liquid ink; Hubbard pycnometer can be used for paste ink, etc. But the errors are relatively large.

- 1Application of Specific Gravity Cup in Coating Density Detection

- 2Significance and method of INKS surface tension detection

- 3Testing and test methods for performance of different inks

- 4Paint specific gravity detection method

- 5Frequently Asked Questions about the 2022 Gravity Cup

- 6What is specific gravity? How to measure it?

- 7Determination of Wear Resistance of Ink Film by Abrasion Meter

- 8Thixotropy - the viscosity of inks and paints

- 9What are the subjects of ink testing for food, pharmaceutical and other packaging?