Process principle of preparing polymer thin films by phase conversion method

Among all membrane-making methods, the phase inversion method is the most important and the most practical one. Phase inversion refers to the process of changing the homogeneous membrane-forming solution from the liquid phase to the solid phase through the volatilization of the solvent or adding the non-solvent to the phase solution or heating the membrane-forming solution . After the phase separation of the polymer solution, the polymer-rich phase solidifies into a porous membrane structure, while the polymer-poor phase occupies the pore space. According to the cause of phase inversion, the film forming process can be divided into: temperature change process (thermally induced phase inversion); concentration change process (addition of non-solvent from vapor phase, solvent evaporation, immersion in non-solvent). Among them, the method of immersing in non- solvent has the characteristics of fast speed and controllable production of various structures, so it is the main research object.

In 1960, Loeb and Sourirajan used the phase inversion method for the first time to make an asymmetric reverse osmosis membrane. This membrane method is also called the LS type membrane method. The important method in the phase inversion film making process is the LS type film making method. The LS-type film-making method can be roughly divided into the following six stages:

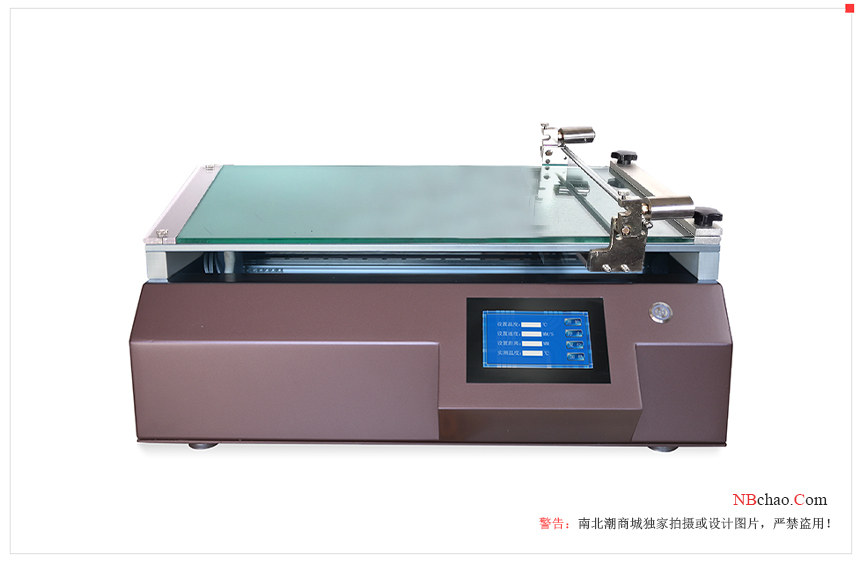

(1) The polymer material is dissolved in a solvent, and additives are added to make a casting solution.

(2) The casting solution is made into a flat plate type and a round tube type by a salivation method, and a hollow fiber is made by a spinning method.

(3) Partially volatilize the solvent in the film.

(4) Immerse the membrane in a liquid that is a coagulant for polymers, and the liquid membrane will gel and solidify in water.

(5) Heat treatment, this step is not necessarily used, it can be treated separately according to the material and type of the membrane .

(6) Pre-compression treatment of the membrane to stabilize the membrane structure.

The phase inversion method is generally divided into wet method and dry/wet method. The wet method refers to that after the formation of the nascent film, it is directly immersed in coagulation bath, and the solvent and the polymer phase are separated through the mutual exchange of the solvent and the non-solvent in the coagulation bath. Film immersed information coagulation bath to exchange the solvent with the non-solvent, and finally achieve phase separation.

This article is excerpted from "Research on PVA Blended Temperature Sensitive Film". The copyright belongs to the original author. If there is any infringement, please contact us immediately, and we will deal with it in time!

- 1What problems should be paid attention to in the daily application of Leeb Hardness Tester?

刘吉萍 - 《里氏硬度计使用时应注意的几个问题》

- 2Introduction to the Application of Electronic Balance in Pharmaceutical Industry

王青 - 《电子天平在制药行业中的应用》

- 3Corrosion behavior and surface oxide of Cold rolled steel plate

王印旭; 胡凡; 王佳 - 《冷轧钢板锈蚀行为及表面氧化物影响的研究》

- 4Introduction to the principle and structure of magnetic drive Stirrer

聂鹏飞 - 《磁力传动技术在脱硫侧进式搅拌器上的应用》

- 5Electronic Balance Daily Maintenance and Problem Countermeasures

陆金霞; 周敏 - 《电子天平的使用、维护及故障处理》

- 6What is Grinder and Grinding Principle?